Method for recovering valuable metals from ternary positive electrode material of waste power battery

A technology for positive electrode materials and power batteries, which is applied in the field of recovering valuable metals from waste power battery ternary positive electrode materials, and can solve the problem of low leaching rate of valuable metals, low purity, and high impurities in valuable metal oxides or metal salt solutions and other problems, to achieve the effect of less impurities, high purity, efficient and easy recovery method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

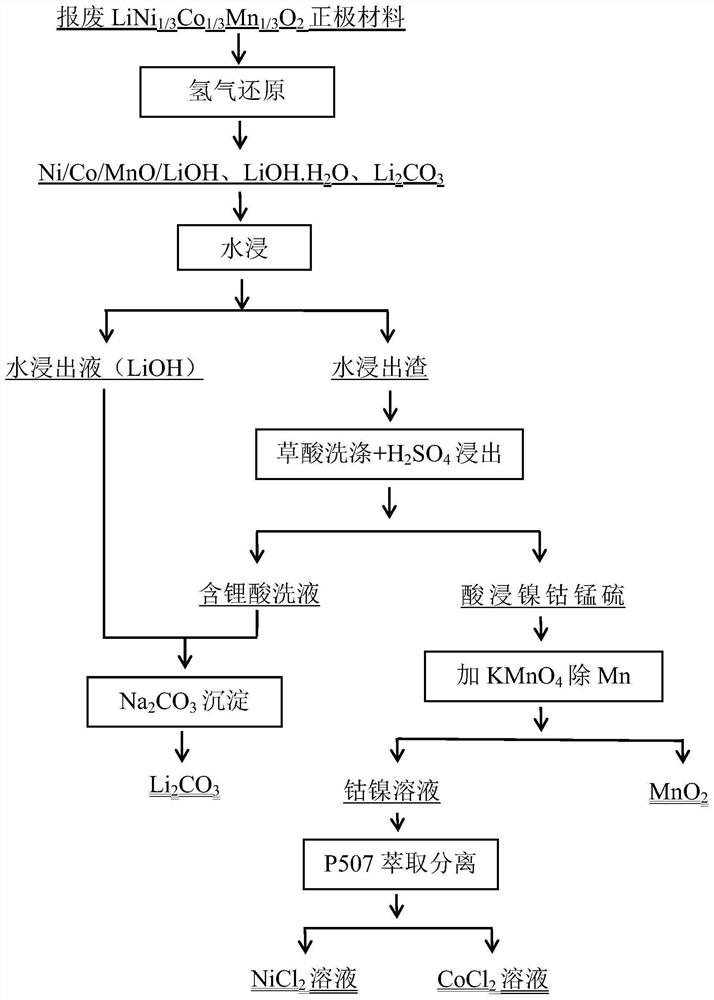

Method used

Image

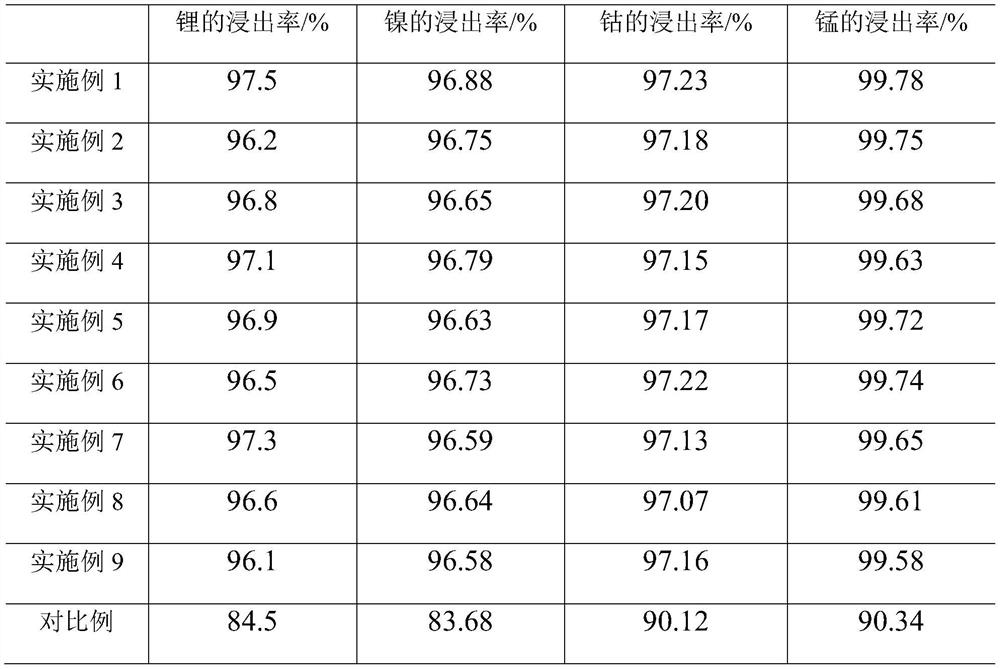

Examples

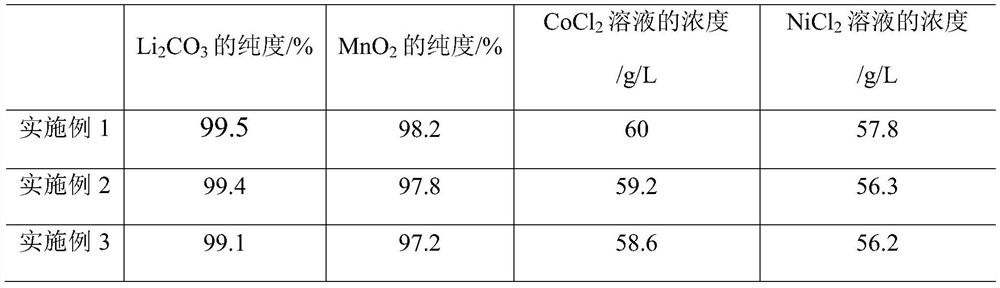

Embodiment 1

[0031] A recovery of valuable metals from waste power battery ternary positive electrode materials is achieved through the following steps:

[0032] Step 1. At 450°C, use a mixed reducing gas of hydrogen and nitrogen with a molar mass ratio of 3:1 to reduce the waste power battery ternary positive electrode material for 3 hours to obtain the reduced ternary positive electrode material;

[0033] Step 2, put the reduced ternary positive electrode material described in step 1 into water for water immersion, stir with a stirring speed of 100r / min for 0.5h during water immersion, and then filter to obtain a water leaching solution (lithium-containing leaching solution) and water leaching slag;

[0034] Step 3, the water leaching slag obtained in step 2 is sequentially passed through oxalic acid pickling and sulfuric acid pickling, wherein, during sulfuric acid pickling, it should be stirred at a stirring speed of 100r / min for 2h to obtain pickling solution (lithium-containing pickl...

Embodiment 2

[0039] A recovery of valuable metals from waste power battery ternary positive electrode materials is achieved through the following steps:

[0040] Step 1, at 350°C, use a mixed reducing gas of hydrogen and nitrogen with a molar mass ratio of 2:1 to reduce the waste power battery ternary positive electrode material for 4 hours, and obtain the reduced ternary positive electrode material;

[0041]Step 2, put the reduced ternary positive electrode material described in step 1 into water for water immersion, stir for 2.5h at a stirring speed of 50r / min during water immersion, and then filter to obtain a water leaching solution (lithium-containing leaching solution) and water leaching slag;

[0042] Step 3, the water leaching slag obtained in step 2 is sequentially passed through oxalic acid pickling and sulfuric acid pickling, wherein, during sulfuric acid pickling, it should be stirred at a stirring speed of 50r / min for 2.5h to obtain a pickling solution (lithium-containing pick...

Embodiment 3

[0047] A recovery of valuable metals from waste power battery ternary positive electrode materials is achieved through the following steps:

[0048] Step 1, at 650°C, use a mixed reducing gas of hydrogen and nitrogen with a molar mass ratio of 4:1 to reduce the waste power battery ternary positive electrode material for 2 hours, and obtain the reduced ternary positive electrode material;

[0049] Step 2, put the reduced ternary positive electrode material described in step 1 into water for water immersion, stir for 1.5h at a stirring speed of 150r / min during water immersion, and then filter to obtain a water leaching solution (lithium-containing leaching solution) and water leaching slag;

[0050] Step 3, the water leaching slag obtained in step 2 is sequentially passed through oxalic acid pickling and sulfuric acid pickling, wherein, during sulfuric acid pickling, it should be stirred at a stirring speed of 100r / min for 1.5h to obtain a pickling solution (lithium-containing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com