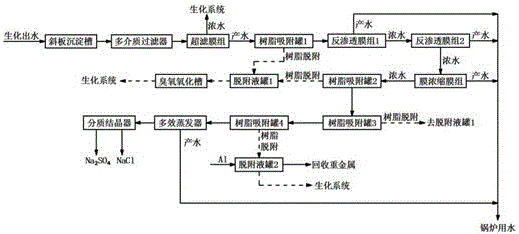

Zero-discharge treatment process for crushed coal pressurized gasification wastewater

A crushed coal pressurized gasification and treatment process technology, applied in the direction of heating water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of difficult and difficult disposal of hazardous waste, and achieve high adsorption rate Fast, chemically stable, chemically stable and easy to regenerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The water quality characteristics of biochemical effluent are: PH=6, CODcr=100mg / L, conductivity=1500μs / cm, turbidity=6NTU, heavy metal ion content 3mg / L.

[0046] (1) After adding 10ppm polyaluminum chloride (PAC) and 2ppm sodium hypochlorite into the biochemical effluent, it enters the inclined plate settling tank for a residence time of 2h. After removing large particles of solid particles (SS) in the water by precipitation, it enters the upper layer It is fruit shell, with a particle size of 0.9-1.2mm, accounting for 40% of the height of the packing layer. The middle layer is quartz sand, with a particle size of 1.6-2mm, accounting for 50% of the height of the packing layer. The lower layer is quartz sand, with a particle size of 3-3.5mm. Accounting for 10% of the height of the packing layer, the operating pressure is 0.3MPa, and the filtration speed is 12m / h. The multi-media filter removes the unsettled suspended solids and colloidal particles, and enters the coiled...

Embodiment 2

[0056] The water quality characteristics of biochemical effluent are: PH=7.2, CODcr=200mg / L, conductivity=2230μs / cm, turbidity=14NTU, heavy metal ion content 5mg / L.

[0057] (1) After adding 40ppm of polyacrylamide (PAM) and 3ppm of sodium hypochlorite into the biochemical effluent, it enters the inclined plate settling tank for a residence time of 3h. After removing large particles of solid particles (SS) in the water by precipitation, it enters the upper layer for The shell, with a particle size of 0.8-1.2mm, accounts for 50% of the height of the packing layer; the middle layer is quartz sand, with a particle size of 1.4-1.8mm, accounting for 35% of the height of the packing layer; the lower layer is quartz sand, with a particle size of 2.5-3mm, accounting for 15% of the height of the packing layer, the operating pressure is 0.4MPa, and the filtration speed is 9m / h. The multi-media filter removes the suspended solids and colloidal particles that cannot be precipitated, and en...

Embodiment 3

[0067] The water quality characteristics of biochemical effluent are: PH=8, CODcr=300mg / L, conductivity=3000μs / cm, turbidity=20NTU, heavy metal ion content 8mg / L.

[0068] (1) Add 30ppm of polyacrylamide (PAM) + 70ppm of polyferric sulfate (PFS) and 5ppm of chlorine dioxide into the biochemical effluent and enter it into the inclined plate settling tank for a residence time of 4h to remove large particles in the water by precipitation After the solid particles (SS) enter the upper layer, they are fruit shells, with a particle size of 0.6-1.0mm, accounting for 60% of the height of the packing layer. The middle layer is quartz sand, with a particle size of 1.2-1.6mm, accounting for 35% of the height of the packing layer. It is quartz sand with a particle size of 2.0-3.0mm, which accounts for 5% of the height of the packing layer. The operating pressure is 0.5MPa, and the multimedia filter with a filtration speed of 5m / h removes suspended solids and colloidal particles that have n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com