A kind of preparation method of array type porous oxide thin film

A porous oxide, array-type technology, applied to the surface coating liquid device, pre-treated surface, coating, etc., can solve the problems of poor repeatability, difficulty in large-scale popularization, difficulty in ensuring product uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example provides a method for preparing an arrayed porous oxide thin film, the steps comprising:

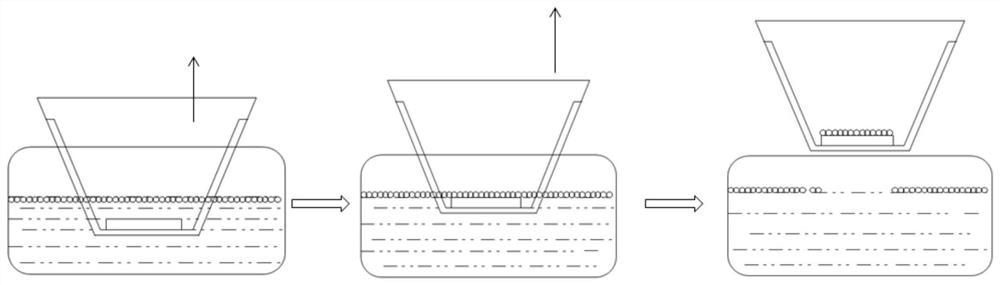

[0039] S1: placing the substrate at the bottom of the filter basket 10, and then immersing the filter basket 10 in the precursor solution 50;

[0040] S2: drop the microsphere solution onto the surface of the precursor solution 50;

[0041] S3: lift the filter basket 10 up to the bottom of the filter basket 10 to leave the precursor solution, take out the substrate 30 and heat to obtain the precursor film;

[0042] S4: heating the precursor thin film and then sintering to obtain the arrayed porous oxide thin film;

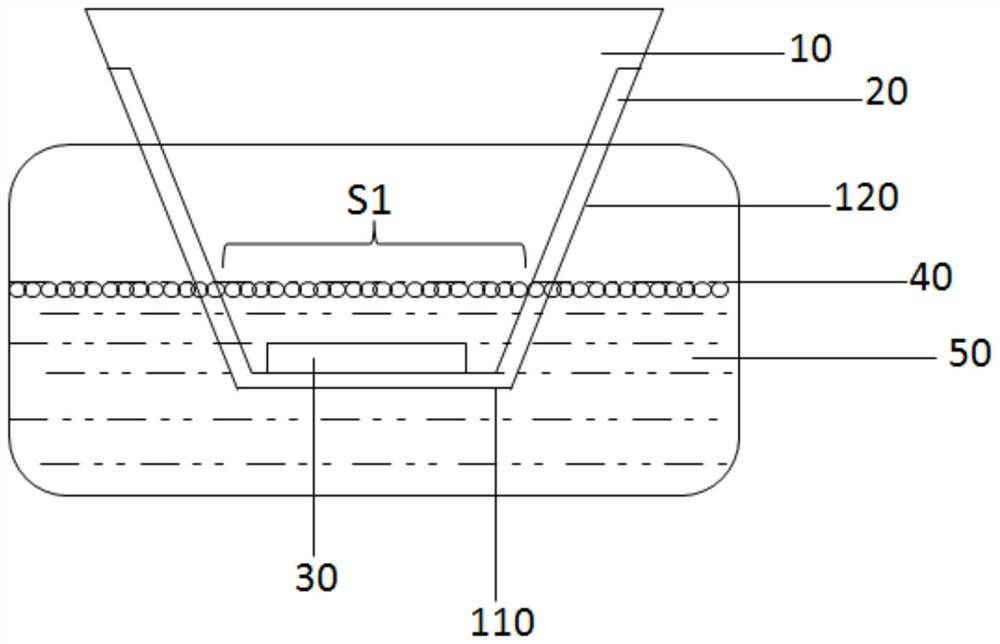

[0043] like figure 1 As shown, the filter basket 10 has a bottom plate 110 and a side wall 120 formed around the bottom plate 110. Filter holes (not shown in the figure) are distributed on the bottom plate 110. The included angle is 120°.

[0044] like figure 2 As shown, as the filter basket is lifted, the microspheres originally suspended on the sur...

Embodiment 2

[0060] This example provides a method for preparing an arrayed porous oxide film. The difference between this example and Example 1 is that in this example, the side wall 120 of the filter basket 10 and the bottom plate 110 form a right angle. like Figure 4 shown.

[0061] When the angle between the side wall 120 of the filter basket 10 and the bottom plate 110 is greater than 90°, the liquid surface area S1 of the precursor solution 50 in the filter basket 10 will gradually decrease with the lifting of the filter basket, which is more conducive to gathering and suspending the liquid. The microspheres 40 make the microspheres 40 form a regular and dense arrangement. When the angle between the side wall 120 of the filter basket 10 and the bottom plate 110 is 90°, the liquid surface area S1 of the precursor solution 50 in the filter basket 10 will remain constant as the filter basket is raised.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com