Method for recovering barium sulfate in the desulfurization process of extracting and refining wet-process phosphoric acid

A technology of wet-process phosphoric acid and recovery method, applied in chemical instruments and methods, calcium/strontium/barium sulfate, calcium/strontium/barium compounds, etc., can solve the problem of long purification process production line, high process operation intensity and complex reaction system and other problems, to achieve the effect of high cost performance, high product quality and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

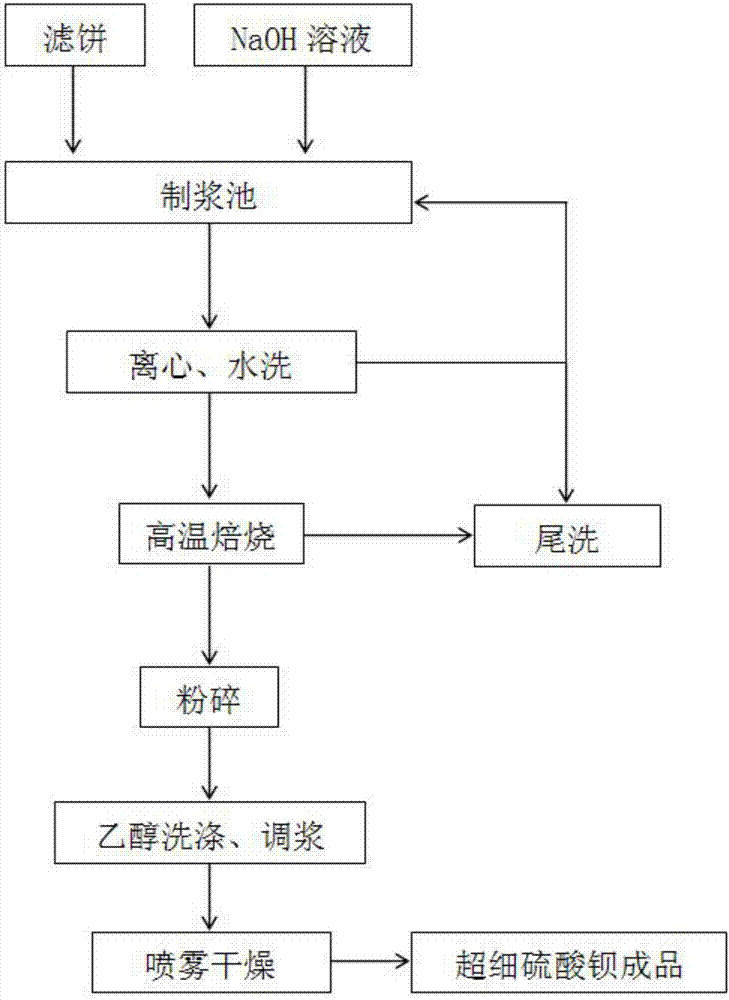

[0092] see Figure 1 to Figure 14 , a method for recovering barium sulfate in the desulfurization process in extracting and refining wet-process phosphoric acid, the recovery method comprising the following steps in turn:

[0093] Pulping and centrifugation process: first put the barium sulfate filter cake in the sodium hydroxide solution pool and stir evenly. The mass percentage concentration of the sodium hydroxide solution is 5%, and the stirring time is 0.5 hours, and then the slurry obtained by stirring is transported Centrifuge in a centrifuge to obtain the initial filter cake, then wash the initial filter cake with hot water to obtain the final filter cake, the washing temperature of the hot water is 75°C; wherein the barium sulfate filter cake includes barium sulfate and an organic sedimentation agent, and The mass percent concentration of barium sulfate is greater than or equal to 90%;

[0094] High-temperature roasting process: put the above-mentioned final filter c...

Embodiment 2

[0098] Basic content embodiment 1, the difference is:

[0099] Pulping and centrifugation process: the mass percentage concentration of sodium hydroxide solution is 5%, the stirring time is 1 hour, and the washing temperature of hot water is 75°C;

[0100] High-temperature roasting process: the roasting temperature is 600°C, and the roasting time is 1 hour;

[0101] Ethanol washing and pulping process: the mass percent concentration of the ethanol solution is 80%, and its usage is twice the volume of the filter cake powder; the mass percent concentration of the barium sulfate slurry is 75%;

[0102] Spray drying process: the spray drying temperature is 180°C, the properties of the barium sulfate powder are: barium sulfate content is equal to 99.9%, whiteness > 99.8, D 50 =0.15μm, moisture<0.05%.

Embodiment 3

[0104] Basic content embodiment 1, the difference is:

[0105] Pulping and centrifugation process: the mass percentage concentration of sodium hydroxide solution is 3%, the stirring time is 0.8 hours, and the washing temperature of hot water is 72°C;

[0106] High-temperature roasting process: the roasting temperature is 800°C, and the roasting time is 0.5 hours;

[0107] Ethanol washing and pulping process: the mass percentage concentration of the ethanol solution is 70%, and its usage is 2.5 times the volume of the filter cake powder; the mass percentage concentration of the barium sulfate slurry is 65%;

[0108] Spray drying process: the spray drying temperature is 160°C, the properties of the barium sulfate powder are: barium sulfate content is equal to 99.8%, whiteness > 99.8, D 50 =0.16μm, moisture<0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com