Synthetic method of tungsten oxide nano-wires for preparing gas sensitive sensors

A technology of tungsten oxide nanowires and gas sensor, which is applied in the field of synthesis of tungsten oxide nanowires, can solve problems such as easy residue of organic matter and impact on gas sensing performance, and achieve high crystallization degree, high safety, and easy promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The synthesis method for preparing the tungsten oxide nanowires of the gas sensor of the present invention, the specific synthesis steps include:

[0028] (1) Tungsten hexachloride is placed in dehydrated alcohol;

[0029] Dissolve a predetermined amount of tungsten hexachloride in absolute ethanol, the mass ratio of ethanol to tungsten hexachloride is 1000:0.5~20, stir on a magnetic stirrer for 0.5~1 hour, after completely dissolving, light green hexachloride is obtained. Tungsten chloride alcohol solution;

[0030] (2) After stirring evenly, the formed light green tungsten hexachloride alcohol solution is transferred to a stainless steel hydrothermal reaction kettle, and the reaction is carried out at a predetermined temperature for a predetermined time, so that the tungsten hexachloride is completely converted into tungsten oxide;

[0031] Transfer the obtained light green tungsten hexachloride alcohol solution into a stainless steel hydrothermal reaction kettle wit...

Embodiment 1

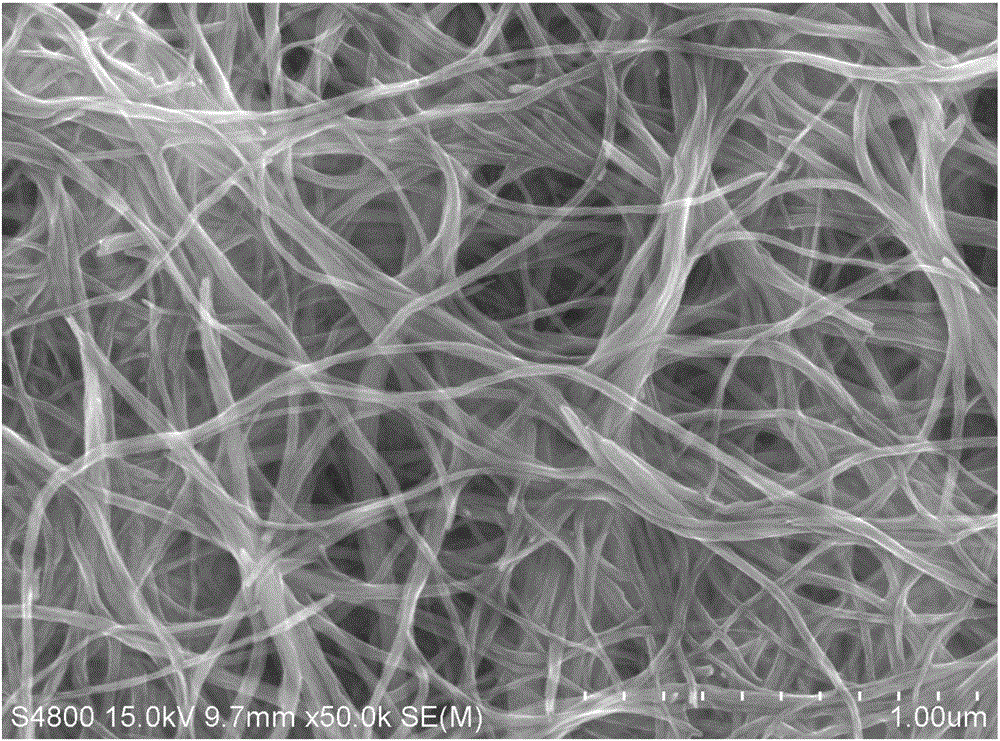

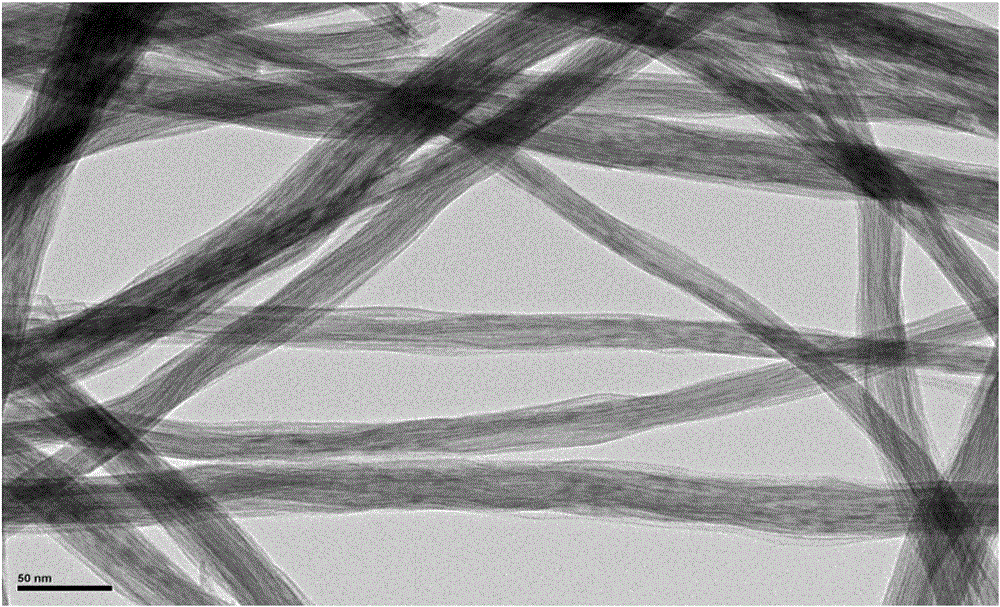

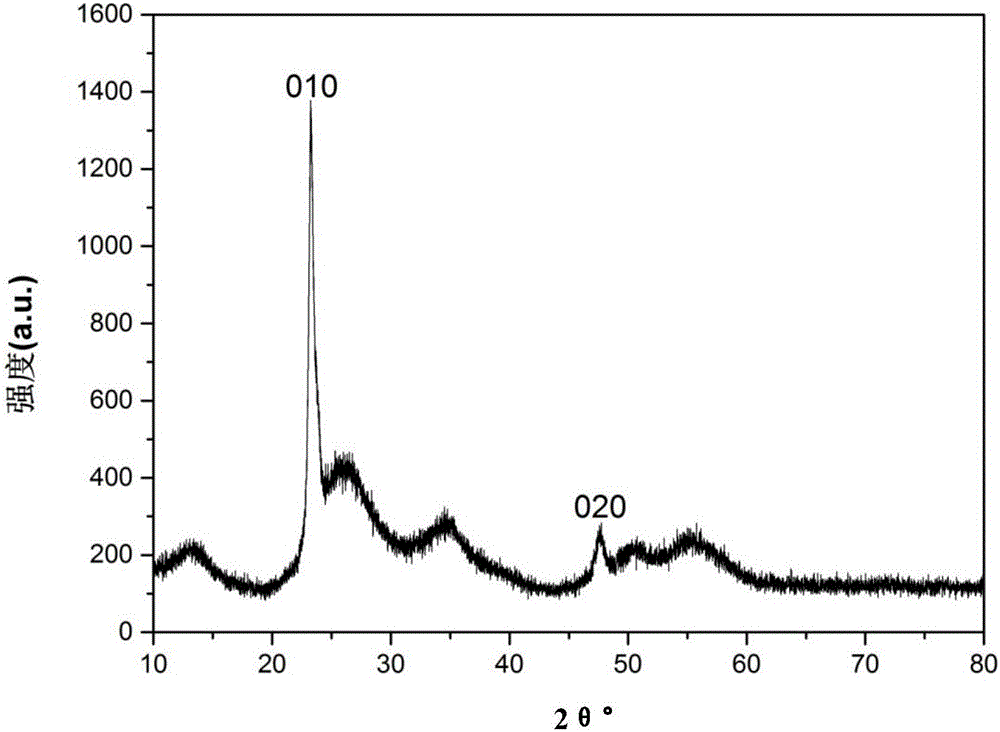

[0041] Weigh 0.3g of tungsten hexachloride, put it in 100mL of absolute ethanol, stir with a magnetic stirrer for half an hour, completely dissolve the tungsten hexachloride, and obtain a light green alcohol solution of tungsten hexachloride. The alcohol solution was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, sealed with a cover, placed in an oven, and heated at 180°C for 24 hours. After the reaction, the obtained product was transferred to a centrifuge tube, centrifuged at 8000 rpm for 10 minutes, and the upper layer liquid was discarded. The centrifuged product was ultrasonically cleaned with ethanol for 10 minutes, centrifuged at a speed of 8000 rpm for 10 minutes, the supernatant was discarded, and the washing was repeated once. Ultrasonic washing was performed twice with excess deionized water, and the washed blue solid product was vacuum-dried. After the obtained product is characterized by SEM, XRD, TEM and EDX, it is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com