Preparation method of high purity WO<3> mesoporous nano-belt

A nanobelt, high-purity technology, applied in the direction of textiles and papermaking, fiber treatment, artificial filament of inorganic raw materials, etc., can solve the problems of complex process and low purity, and achieve the effect of simple process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

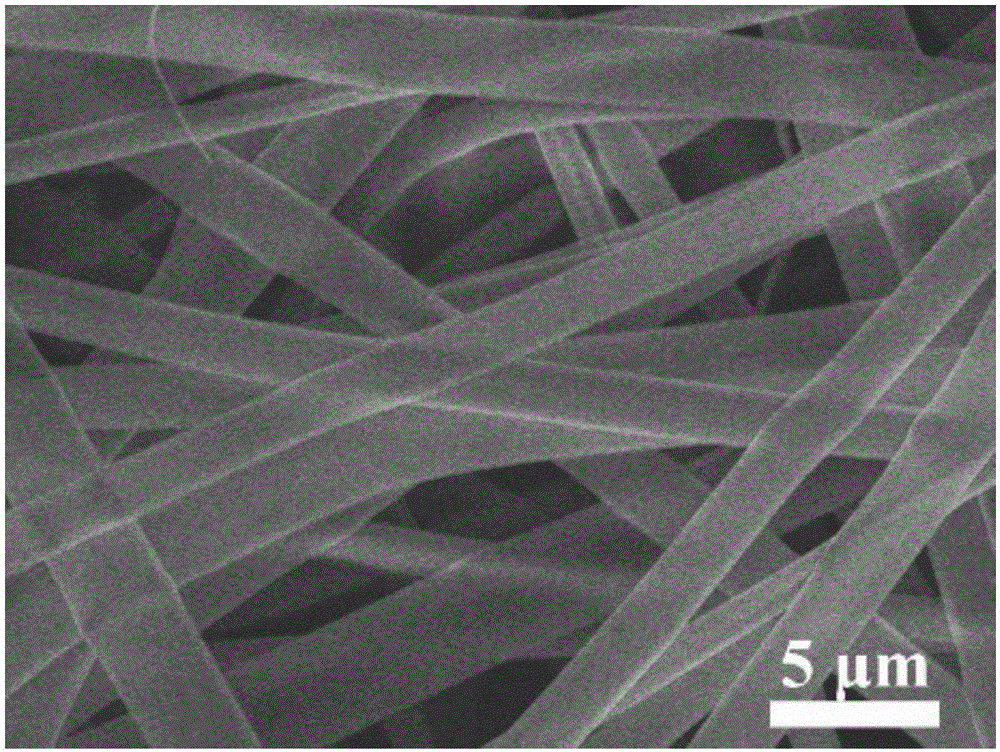

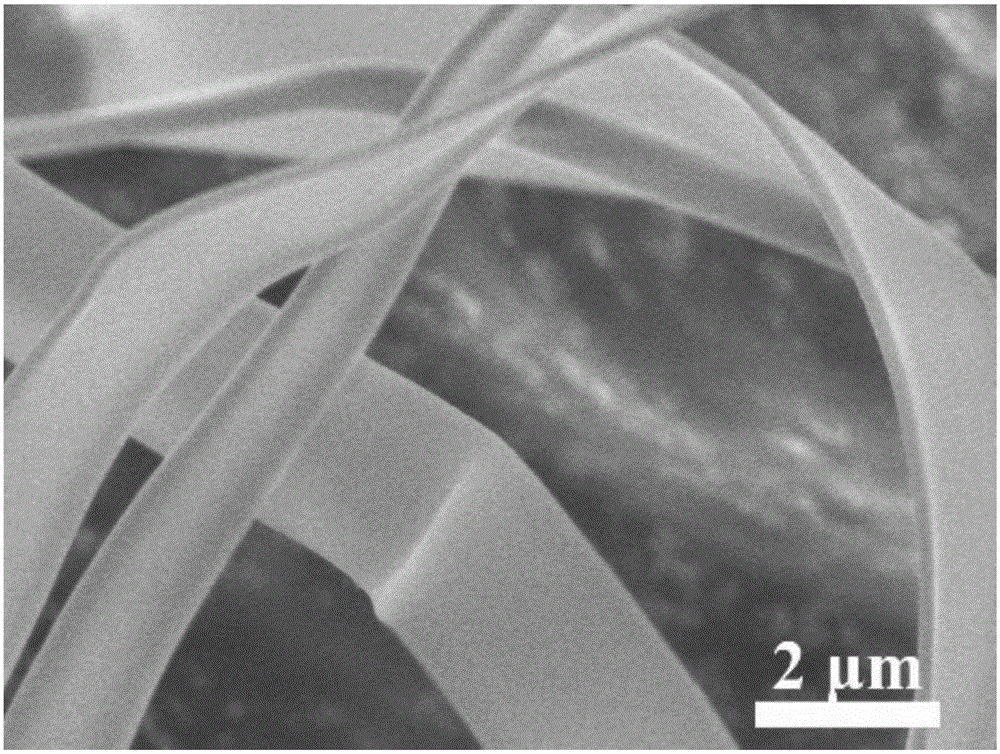

[0050] Measure 1ml of absolute ethanol and 4ml of N,N-dimethylformamide (DMF) into a conical flask, weigh 0.4g of polyvinylpyrrolidone (PVP) and slowly add to the weighed In the mixed solution of water ethanol and DMF, stir at room temperature for 2h until a clear and transparent PVP solution is obtained; then weigh 2g of WCl 6 Quickly add to the dispersed PVP solution and continue to stir at room temperature for 0.5h until clear dark blue WCl is formed 6 / PVP solution; then weigh 0.8g of tea saponin and quickly add to the dispersed WCl 6 / PVP solution, continue to stir at room temperature for 0.5h until clear dark blue WCl is formed 6 / PVP / Tea-saponin solution.

[0051] After the prepared precursor spinning solution is left to stand, it is injected into the plastic needle tube and placed horizontally on the spinning machine. The metal needle (0.22mm) is used as the electrospinning anode, and the barbed wire is used as the cathode of the receiving material. The distance bet...

Embodiment 2

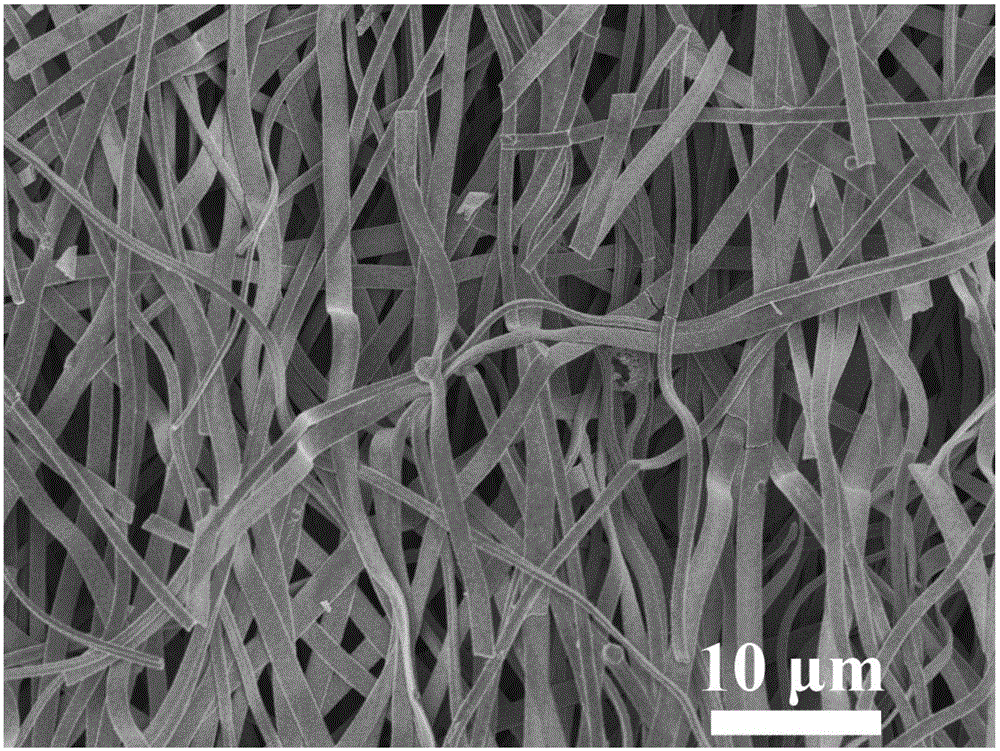

[0054] The only difference from Example 1 is the addition of 0.2g tea saponin, and the other processes are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0056] Only difference with embodiment 1 is adding 0.5g tea saponin, other processes are identical with embodiment 1, repeat no more here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com