Preparation method of nitric oxide gas sensor element based on pseudodirected tungsten trioxide nano tape

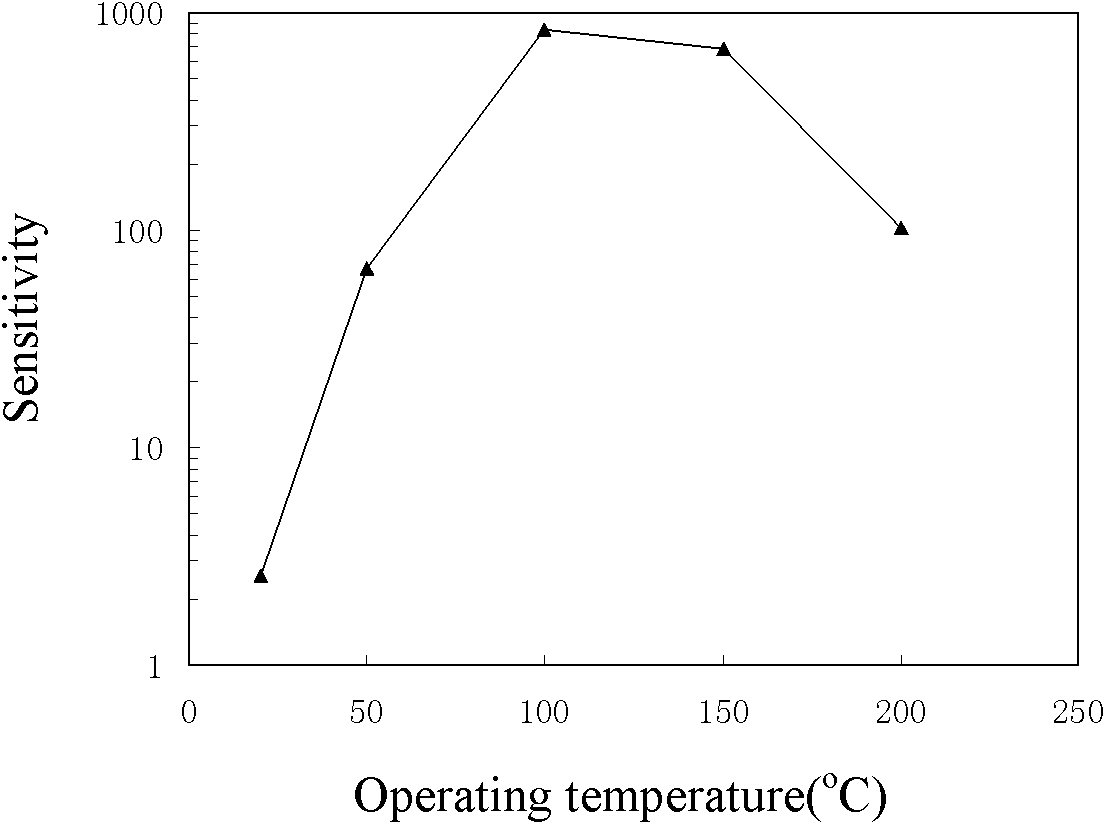

A technology of gas sensor and nitrogen oxide, which is applied in the direction of material resistance, can solve the problems of low sensitivity and high power consumption of nitrogen oxide gas, and achieve the effects of low power consumption, low operating temperature and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

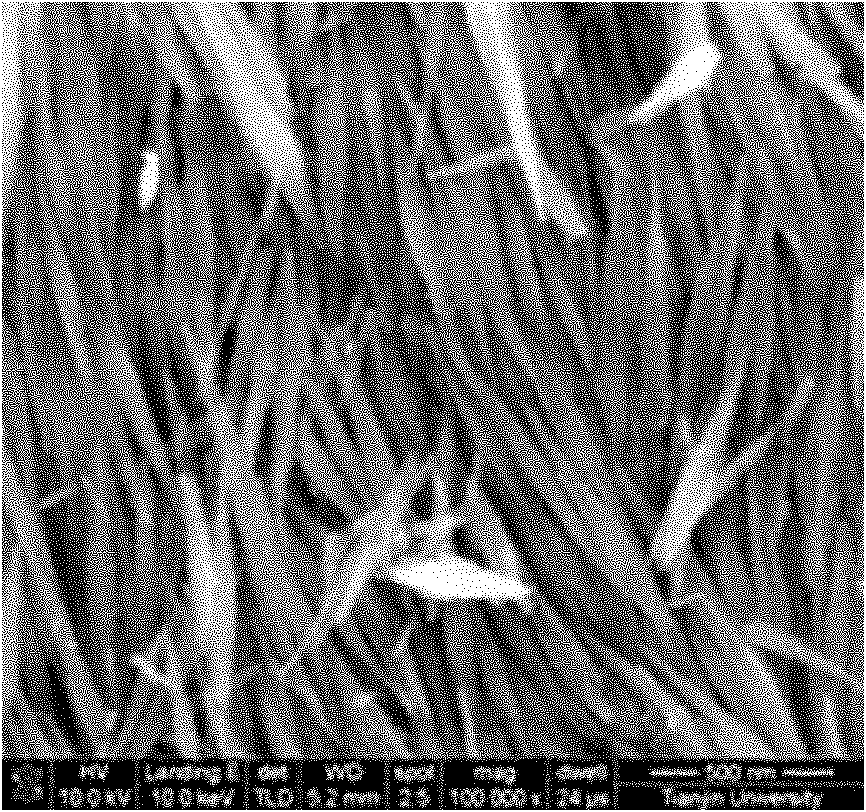

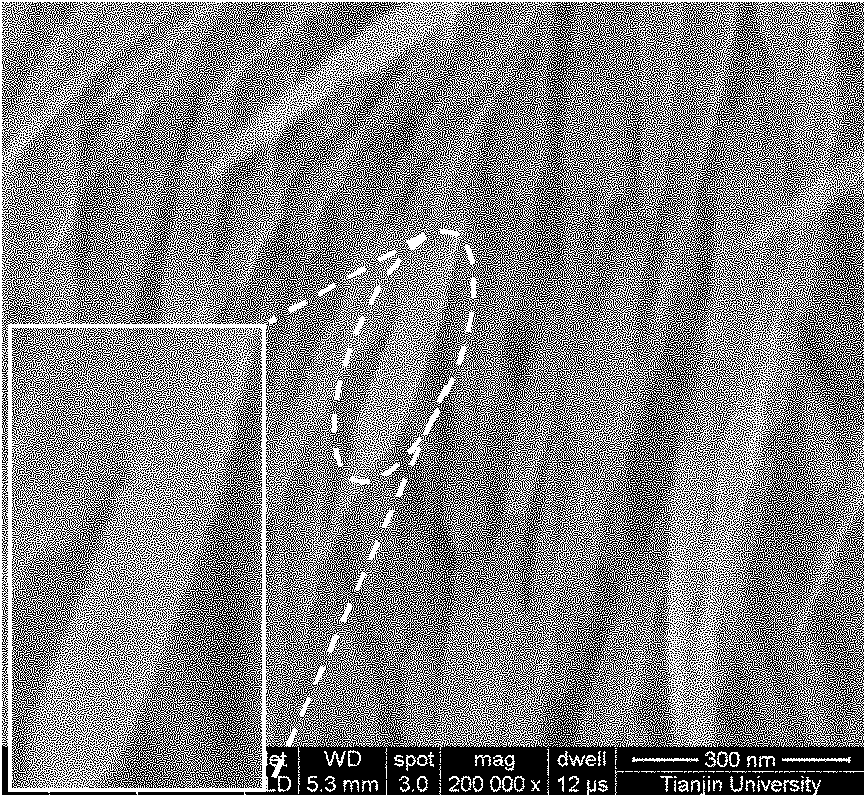

[0021] The present invention uses WCl 6 As the reactive W source, the quasi-oriented tungsten oxide nanowire bundle was synthesized by the solvothermal method, and the organic slurry of the tungsten oxide nanowire bundle was coated on the surface of the sensor substrate, and annealed in air atmosphere to form a quasi-oriented tungsten trioxide nanobelt-based gas sensor. element.

[0022] The raw materials used in the present invention all adopt commercially available chemically pure reagents, with WCl 6 As the reaction W source, using n-propanol or cyclohexanol as the synthesis solvent, the quasi-aligned tungsten oxide nanowire bundle was synthesized by solvothermal method [steps (1)-(4)]. Examples are shown in Table 1.

[0023] Table 1

[0024]

[0025] Using the quasi-aligned tungsten oxide nanowire bundle prepared in Table 1 as the initial material, prepare the quasi-oriented tungsten trioxide nanobelt-based gas sensor element [steps (5)-(6)]. See Table 2 for specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com