Preparation method of composite hollow microspheres with improved triethylamine detection performance

A technology of hollow microspheres and triethylamine, which is applied in the preparation of microspheres, microcapsule preparations, measuring devices, etc., to achieve the effects of high sensitivity, low cost, and wide-concentration linear response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, 0.2g W 18 O 49 The hollow microsphere powder sample was dispersed in 20mL Co(NO 3 ) 2 In the ethanol solution, put it in an oven to volatilize the ethanol to obtain a powder sample, which is calcined and dried for 2 hours in an air atmosphere at 300°C to obtain W 18 O 49 / Co 3 O 4 Composite hollow microspheres.

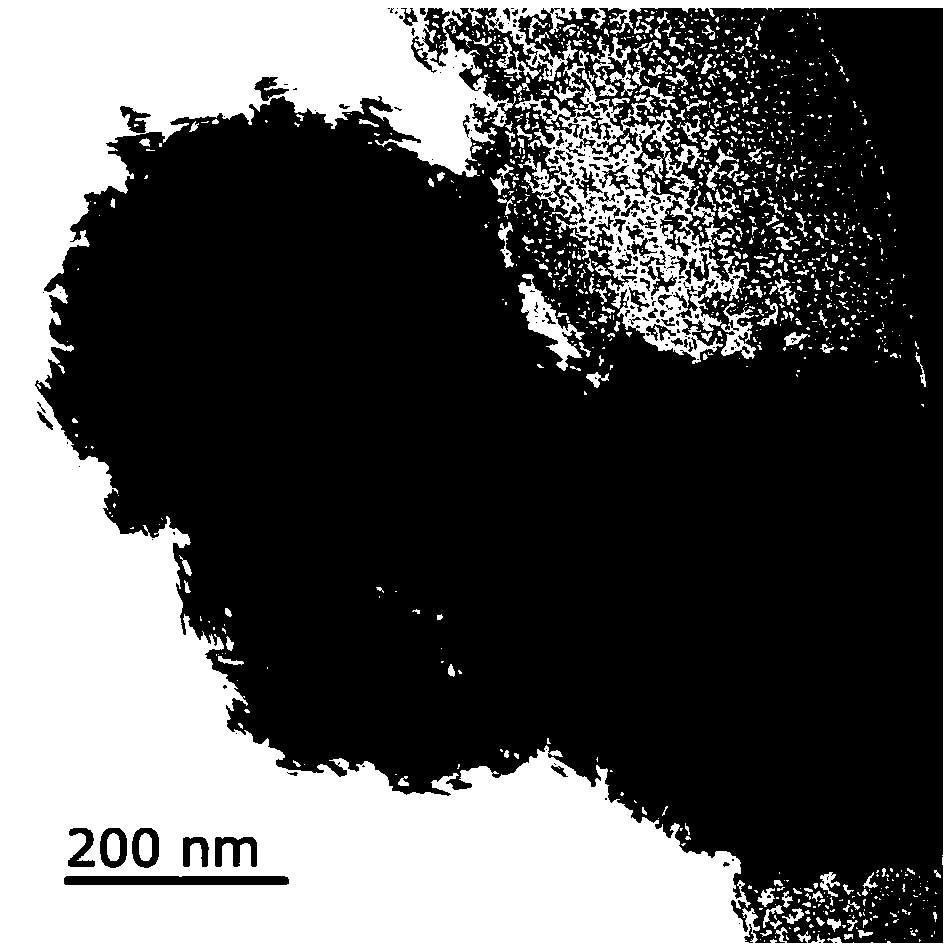

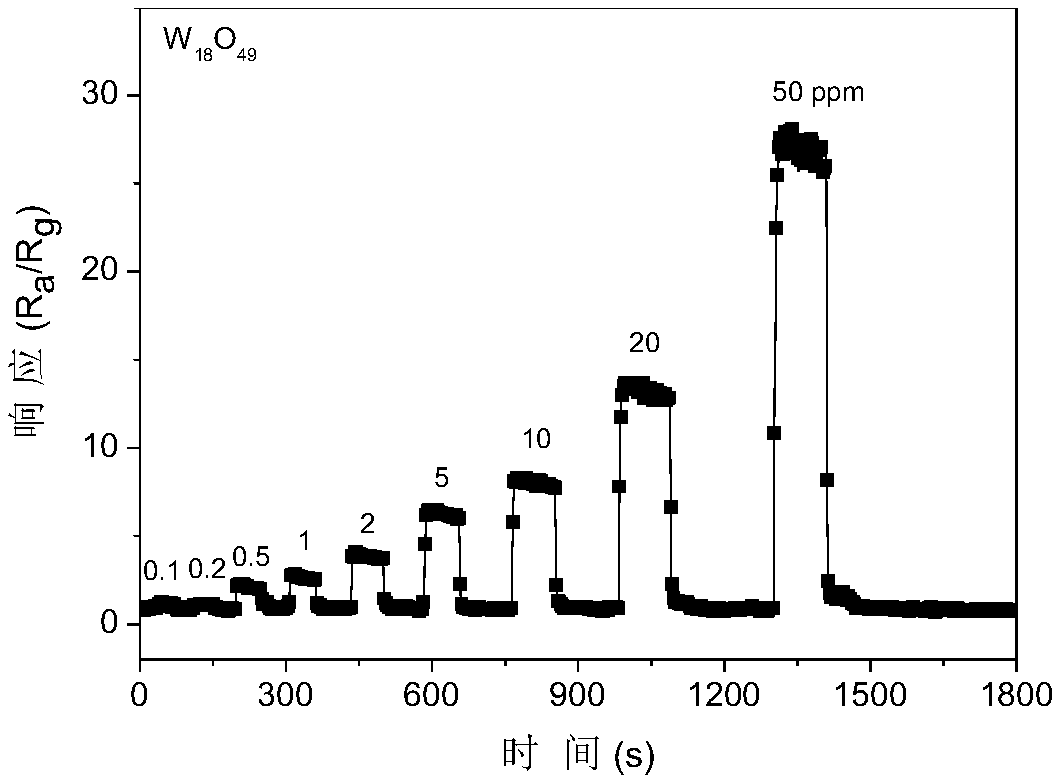

[0028] W 18 O 49 / Co 3 O 4 TEM characterization of composite hollow microspheres, the results are as follows Figure 5 As shown, the sample has a hollow structure, the spherical shell has a typical layered structure, the diameter of the microspheres is 400-600 microns, but the tube wall is relatively thick; the HRTEM characterization results show that Image 6 As shown, the spherical shell has a highly crystalline structure, and the lattice fringes correspond to W 18 O 49 (010) and Co 3 O 4 The (220) crystal plane; the gas sensitivity test on it, the result is as Figure 7 As shown, the sample has better response-recovery characteristics to 0.1-5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com