Method for preparing mesoporous WO3/SBA-15 molecular sieve

A technology of molecular sieve and mesoporous, which is applied in the field of preparation of mesoporous WO3/SBA-15 molecular sieve, to achieve the effect of improving olefin disproportionation reaction performance, good technical effect and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Synthesis of all-silicon SBA-15

[0025] With electromagnetic stirring, weigh 60 ml of concentrated hydrochloric acid (concentration 38%) and dissolve it in 312 ml of deionized water, and keep the temperature in a water bath at 40°C. Then add 12 grams of polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer (Aldrich, molecular formula is H(-OCH 2 -CH 2 -) x [-OCH(CH 3 )CH 2 -] y (OCH 2 CH 2 -) z OH, the molar ratio of x:y:z is 20:70:20, the average molecular weight is 5800, referred to as P123), and stirred at constant temperature for 4 hours to obtain solution A. 25.6 g of tetraethyl orthosilicate (TEOS) was slowly added dropwise to A, and vigorously stirred at 40° C. for 24 hours to obtain milky white suspension B. The gel was transferred to a 200 ml autoclave with a Teflon liner and subjected to static crystallization at 95°C for 3 days. Filter, wash with deionized water three times, and bake in an oven at 120°C for 24 hours. The ob...

Embodiment 2~5

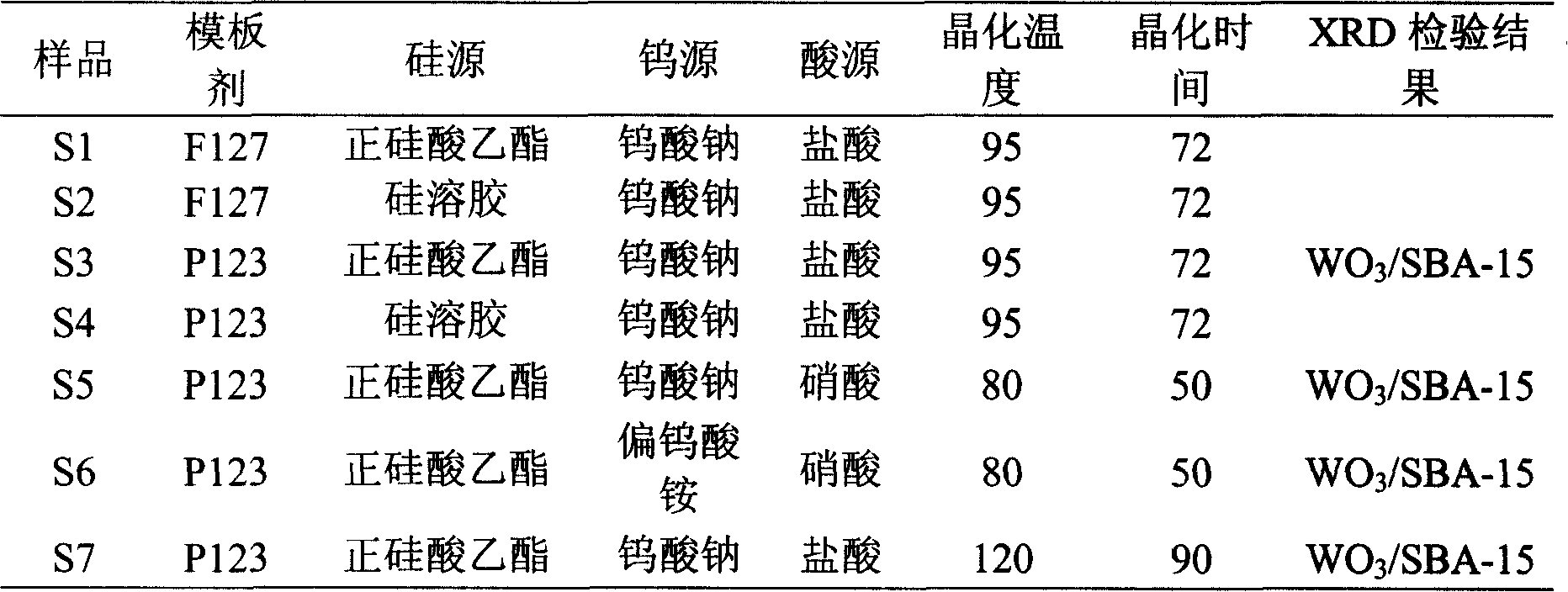

[0027] Synthetic samples S1, S2, S3 and S4

[0028] With electromagnetic stirring, weigh 60 ml of concentrated hydrochloric acid (concentration 38%) and dissolve it in 312 ml of deionized water, and keep the temperature in a water bath at 40°C. Then add 12 grams of polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer P123 (Aldrich, molecular formula is H(-OCH 2 -CH 2 -) x [-OCH(CH 3 )CH 2 -] y (OCH 2 CH 2 -) z OH, the molar ratio of x:y:z is 20:70:20, and the average molecular weight is 5800) and 30 grams of polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer F127 (Aldrich, molecular formula is H( -OCH 2 -CH 2 -) x [-OCH(CH 3 )CH 2 -] y (OCH 2 CH 2 -) zOH, the molar ratio of x:y:z is 106:70:106, and the average molecular weight is 14600), stirred at constant temperature for 4 hours to obtain solutions A and B. 25.6 grams of tetraethyl orthosilicate (TEOS) were slowly added dropwise to A and B respectively to ...

Embodiment 6~7

[0030] Synthetic samples S5 and S6

[0031] With electromagnetic stirring, weigh 300 ml of concentrated nitric acid (concentration 2 mol / L) and dissolve in 100 ml of deionized water, and keep the temperature in a water bath at 40°C. Then respectively add 12 grams of polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer P123 (Aldrich, molecular formula is H(-OCH 2 -CH 2 -) x [-OCH(CH 3 )CH 2 -] y (OCH 2 CH 2 -) z OH, the molar ratio of x:y:z is 20:70:20, and the average molecular weight is 5800), stirred at constant temperature for 4 hours, slowly added dropwise 25.6 grams of tetraethyl orthosilicate (TEOS) and stirred at 40°C for 10 minutes; Add 5 ml of aqueous solutions containing 1.43 g of sodium tungstate and 5 ml of 1.18 g of sodium metatungstate dropwise, and stir vigorously at 40°C for 24 hours to obtain solutions G and H; transfer G and H to 200 ml Static crystallization at 80°C for 50 hours in an autoclave with a Teflon liner. Filter, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com