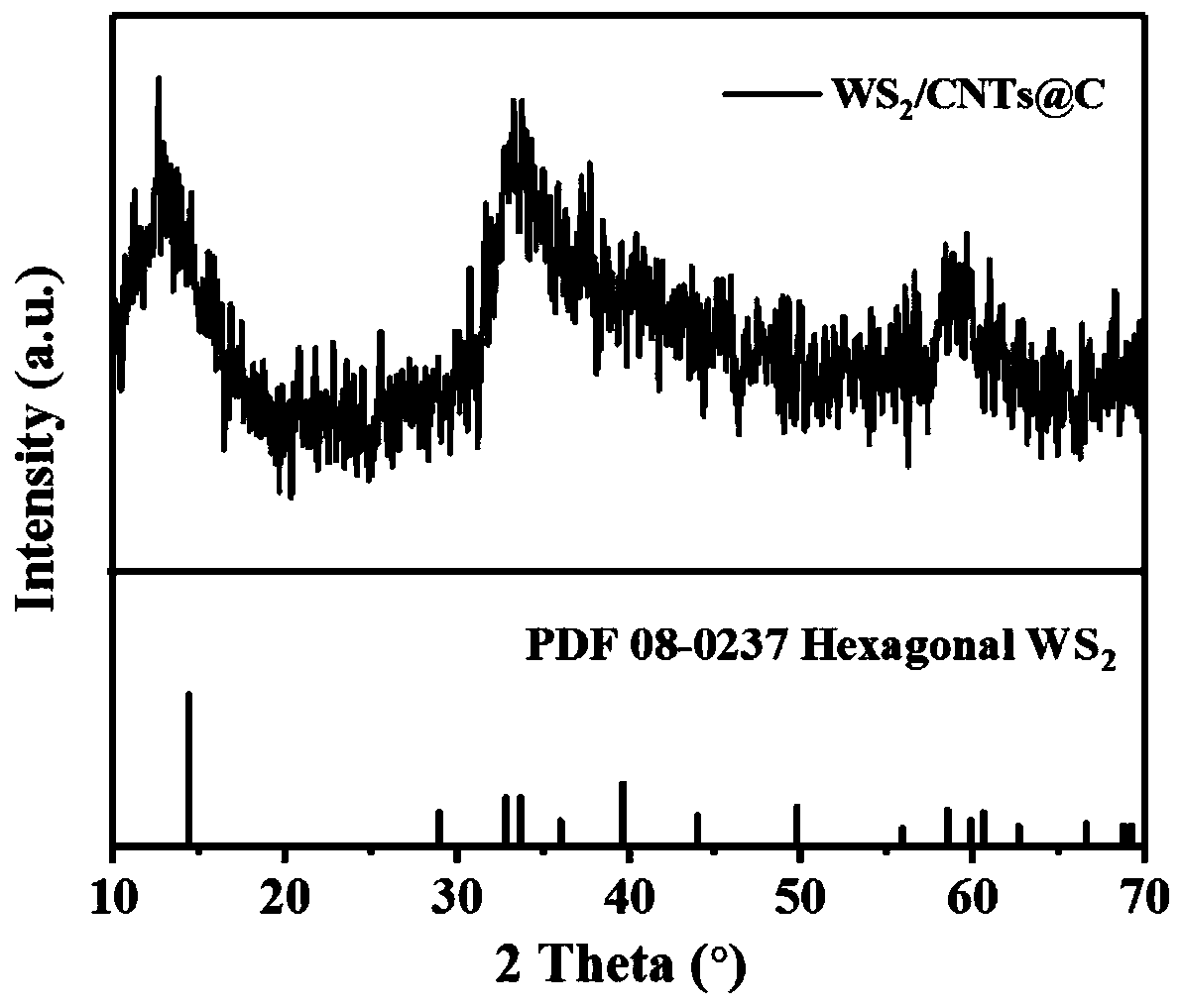

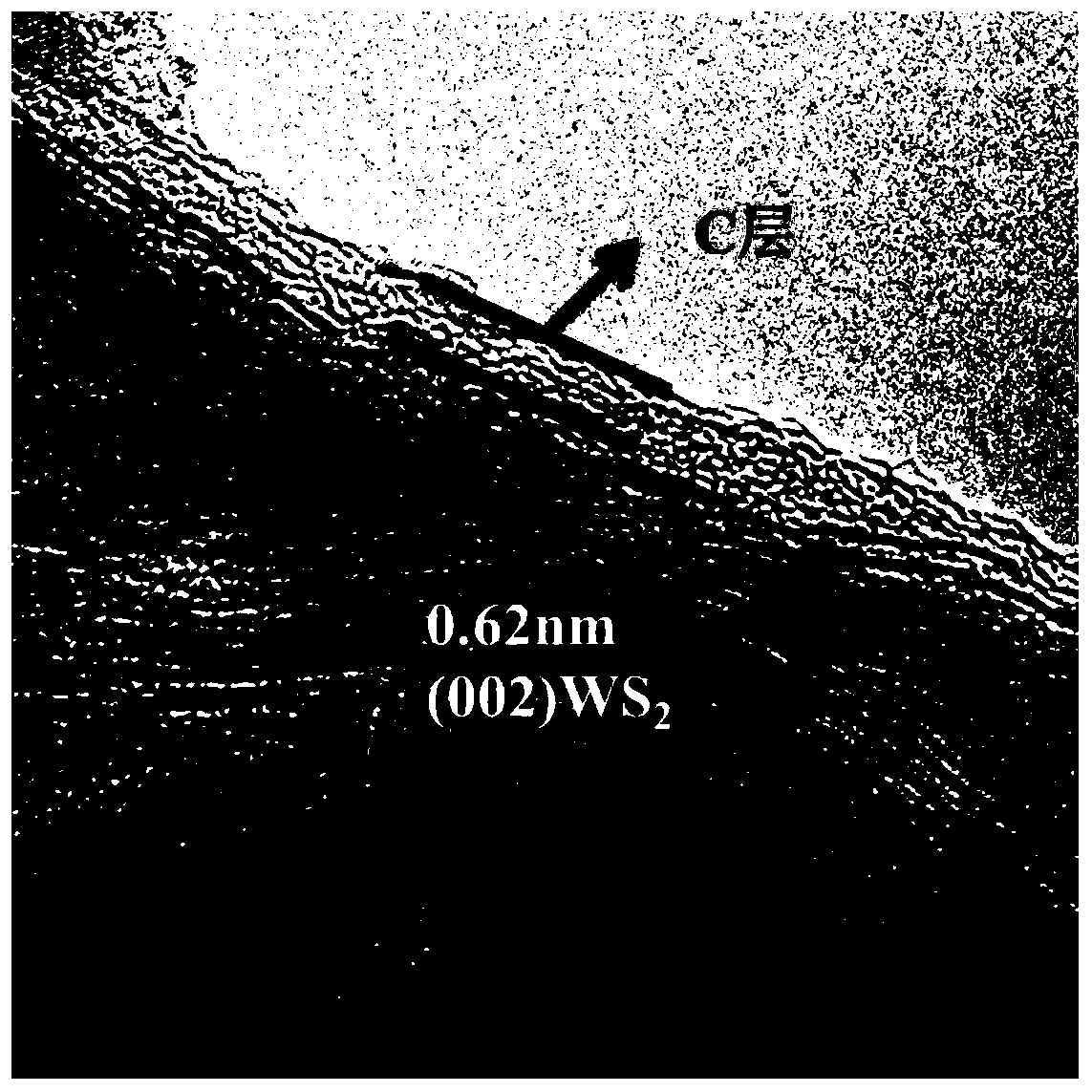

Tungsten sulfide/CNTs (carbon nanotubes)-C composite electrode material and preparation method thereof

A composite electrode and composite material technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problem of further improvement of cycle stability, and achieve the effects of excellent cycle stability, improved electrical conductivity, and shortened reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1: At room temperature, 40 mg of CNTs were added to 40 mL of ethanol solution and ultrasonicated for 2 h. The concentration was controlled to be 1 mg / mL, and the ultrasonic power was 1000 W to form suspension A with better dispersibility.

[0038] Step 2: Add 0.275 g of tungsten hexachloride and 0.5625 g of thioacetamide into suspension A, stirring at a speed of 800 r / min for 3 hours, and the obtained solution is solution B.

[0039] Step 3: Transfer the above solution B to a 100mL microwave hydrothermal kettle, control the filling ratio at 40%, then seal the hydrothermal kettle, put it into a high-throughput ultra-high pressure microwave digestion apparatus, and control the microwave hydrothermal temperature to be 200 ℃, the pressure is 2MPa, the reaction time is 0.5h, after the reaction is completed, it is naturally cooled to room temperature.

[0040] Step 4: Open the microwave reaction kettle, take out the product, wash it with absolute ethanol and deionized wa...

Embodiment 2

[0044] Step 1: Add 60 mg of CNTs to 30 mL of ethanol solution and sonicate for 2 h at room temperature, control the concentration to 2 mg / mL, and the ultrasonic power to 1000 W to form suspension A with better dispersibility.

[0045] Step 2: 0.55g of tungsten hexachloride and 1.125g of thioacetamide were added to suspension A, the stirring speed was 800r / min, and the mixture was stirred for 2h, and the obtained solution was solution B.

[0046] Step 3: Transfer the above solution B to a 100mL microwave hydrothermal kettle, control the filling ratio at 30%, then seal the hydrothermal kettle, put it into a high-throughput ultra-high pressure microwave digestion apparatus, and control the microwave hydrothermal temperature to be 220 ℃, the pressure is 3.5MPa, the reaction time is 2h, after the reaction is completed, it is naturally cooled to room temperature.

[0047] Step 4: Open the microwave reaction kettle, take out the product, wash it with absolute ethanol and deionized wa...

Embodiment 3

[0051] Step 1: At room temperature, 60 mg of CNTs were added to 60 mL of ethanol solution and ultrasonicated for 4 h. The concentration was controlled to be 1 mg / mL, and the ultrasonic power was 800 W to form suspension A with better dispersibility.

[0052] Step 2: 0.38g of tungsten hexachloride and 1.18g of thioacetamide were added to suspension A, the stirring speed was 800r / min, and the mixture was stirred for 1.5h, and the obtained solution was solution B.

[0053] Step 3: Transfer the above solution B to a microwave hydrothermal kettle, control the filling ratio at 60%, then seal the hydrothermal kettle, put it into a high-throughput ultra-high pressure microwave digestion apparatus, and control the microwave hydrothermal temperature to be 210 ° C , the pressure is 1MPa, the reaction time is 4h, and the reaction is naturally cooled to room temperature after the completion of the reaction.

[0054] Step 4: Open the microwave reactor, take out the product, wash it with abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com