Preparation method of WS2 nano-material with macroporous network structure

A technology of network structure and nanomaterials, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limited energy storage performance, limited contact area between carbon materials and electrolyte, and achieve simple and effective preparation methods , Conducive to transmission, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment includes the following steps:

[0019] Step 1, powder mixing

[0020] Weigh 1.1897g tungsten hexachloride (WCl 6 ), 2.2767g thioacetamide (CH 3 CSNH 2 ), added to a beaker with 70ml of deionized water, and magnetically stirred at room temperature for 1h to completely mix the powder materials;

[0021] Step 2, hydrothermal reaction

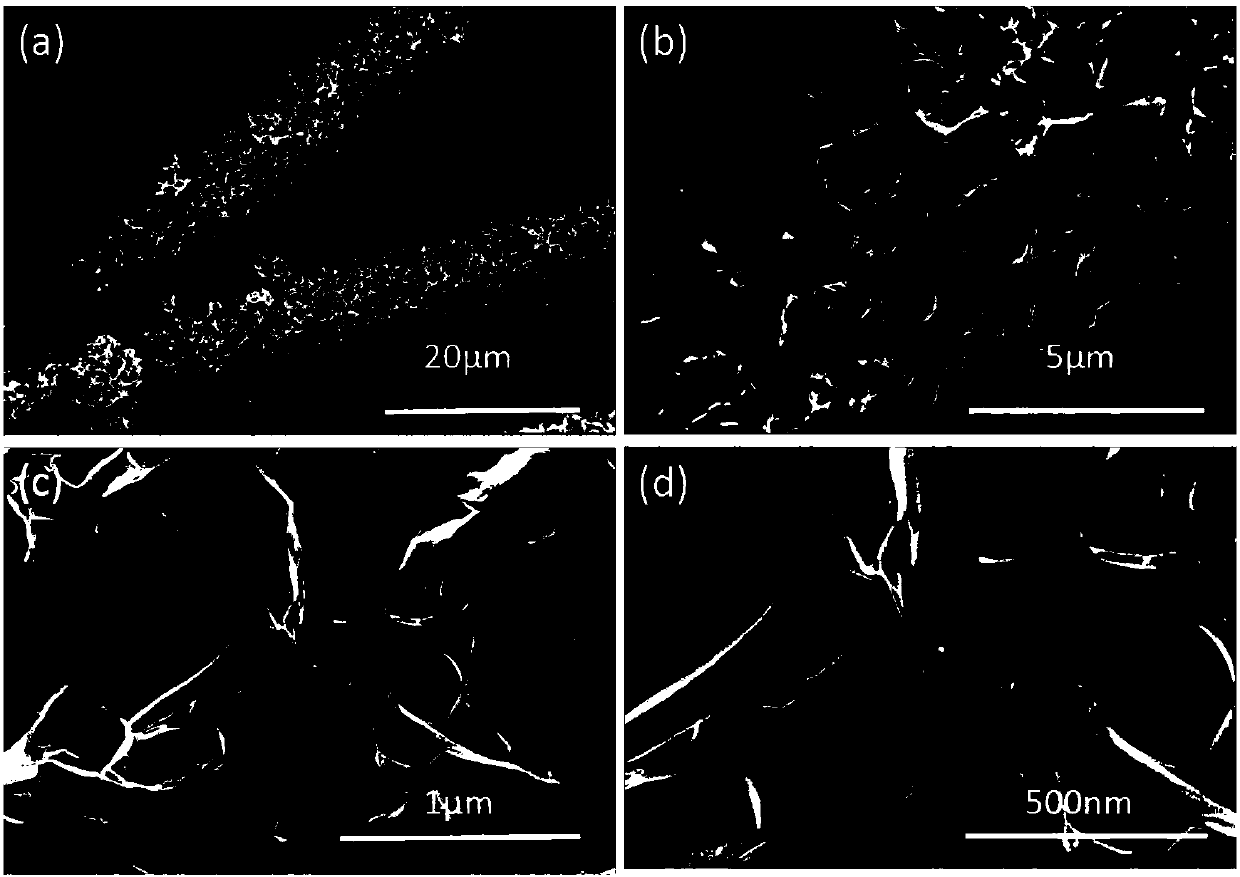

[0022] Transfer the solution obtained in step 1 into a 100ml hydrothermal kettle, and put a 1*2cm carbon cloth, heat it at 265°C, and keep it warm for 24 hours; after the reaction, wash the carbon cloth with absolute ethanol and deionized water respectively 3 times, then vacuum-dried at 60°C and kept for 12 hours. Get WS 2 -carbon paper nanomaterials. Such as figure 1 (a) shows that a uniform macroporous network of WS grows on the surface of nickel foam 2 nanomaterials. From the enlarged pictures of (b)-(d), the macroporous network structure can be clearly seen, and the morphology is complete and evenly distributed....

Embodiment 2

[0026] This embodiment includes the following steps:

[0027] Step 1, powder mixing

[0028] Weigh 1.1897g tungsten hexachloride (WCl 6 ), 1.13835g thioacetamide (CH 3 CSNH 2 ), added to a beaker with 70ml of deionized water, and magnetically stirred at room temperature for 1h to completely mix the powder materials;

[0029] Step 2, hydrothermal reaction

[0030] Transfer the solution obtained in step 1 into a 100ml hydrothermal kettle, and put a 1*2cm carbon cloth, heat it at 265°C, and keep it warm for 24 hours; after the reaction, wash the carbon cloth with absolute ethanol and deionized water respectively 3 times, then vacuum-dried at 60°C and kept for 12 hours to obtain WS 2 -carbon paper nanomaterials.

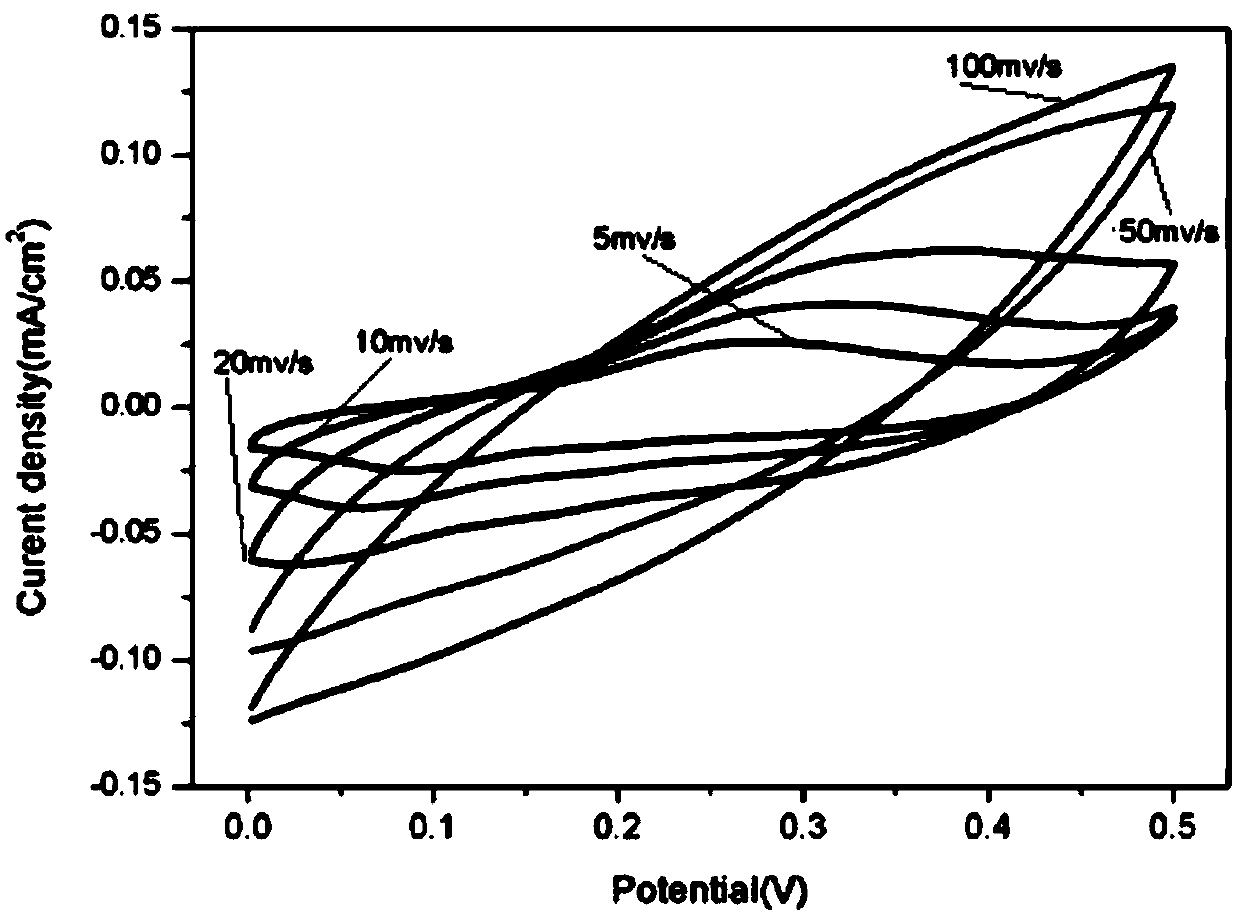

[0031] The carbon cloth obtained in this example is directly used as the working electrode of the three-electrode system, the pt electrode is the counter electrode, the SCE is the reference electrode, and the 1M H 2 SO 4 As the electrolyte, the electrochemical wo...

Embodiment 3

[0033] This embodiment includes the following steps:

[0034] Step 1, powder mixing

[0035] Weigh 1.1897g tungsten hexachloride (WCl 6 ), 2.2767g thioacetamide (CH 3 CSNH 2 ), added to a beaker with 70ml of deionized water, and magnetically stirred at room temperature for 1h to completely mix the powder materials;

[0036] Step 2, hydrothermal reaction

[0037] Transfer the solution obtained in step 1 into a 100ml hydrothermal kettle, and put a 1*2cm carbon cloth, heat it at 200°C, and keep it warm for 24 hours; after the reaction, wash the carbon cloth with absolute ethanol and deionized water respectively 3 times, then vacuum-dried at 60°C and kept for 12 hours to obtain WS 2 -carbon paper nanomaterials.

[0038] The carbon cloth obtained in this example is directly used as the working electrode of the three-electrode system, the pt electrode is the counter electrode, the SCE is the reference electrode, and the 1M H 2 SO 4 As the electrolyte, the electrochemical wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com