Purification method of tungsten hexafluoride gas

A technology of tungsten hexafluoride and purification method, which is applied in the direction of tungsten halide, etc., can solve the problems of low purity of tungsten hexafluoride and non-conformity with electronic grade products, so as to improve product quality and recovery rate, wide range of raw material adaptability, and The effect of less control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

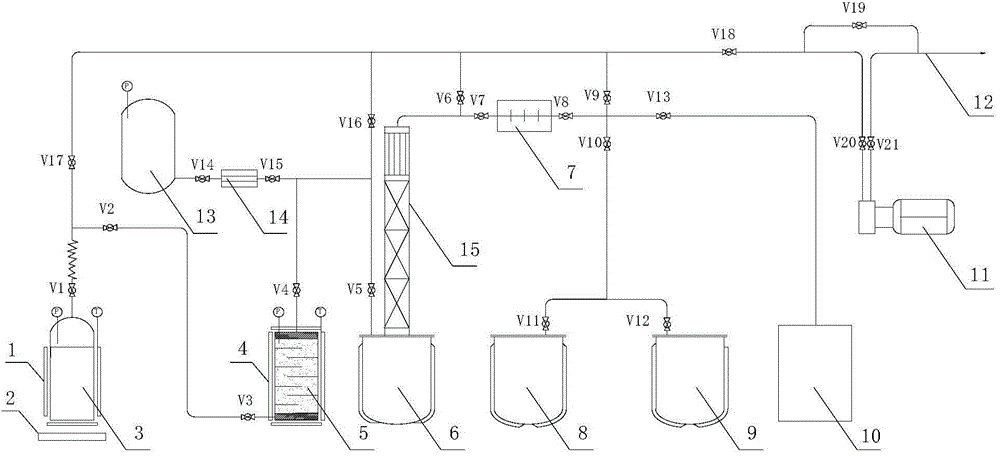

[0027] see figure 1 Firstly, acetone is used to degrease the hydrogen fluoride removal tower 5, the rectifying still 6, the rectifying tower 15, the front collecting tank 8, the finished product collecting tank 9 and the pipelines connected thereto, then clean and dry with ultrapure water, and Install according to the process. Then open the valves V14, V15, V2, V3, V4, V5, V6, V9, V10, V11, V12, V16, V17, fill the pipeline with nitrogen to 0.06MPa, and check each interface with leak detection fluid or soap bubbles. Leak detection until no bubbles appear is qualified. After the leak detection is qualified, add nitrogen pressure to 0.6MPa, close valves V14 and V15, and then keep the pressure for 24 hours. If the pressure drop of the entire purification system is less than 0.01MPa, it is qualified. If the pressure drop is greater than 0.01MPa , it is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com