Preparation method and application of tubular tungsten oxide-graphene composite material

A composite material and tungsten oxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, electrical devices, etc., to achieve improved performance, excellent temperature-sensitive characteristics, and quality controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

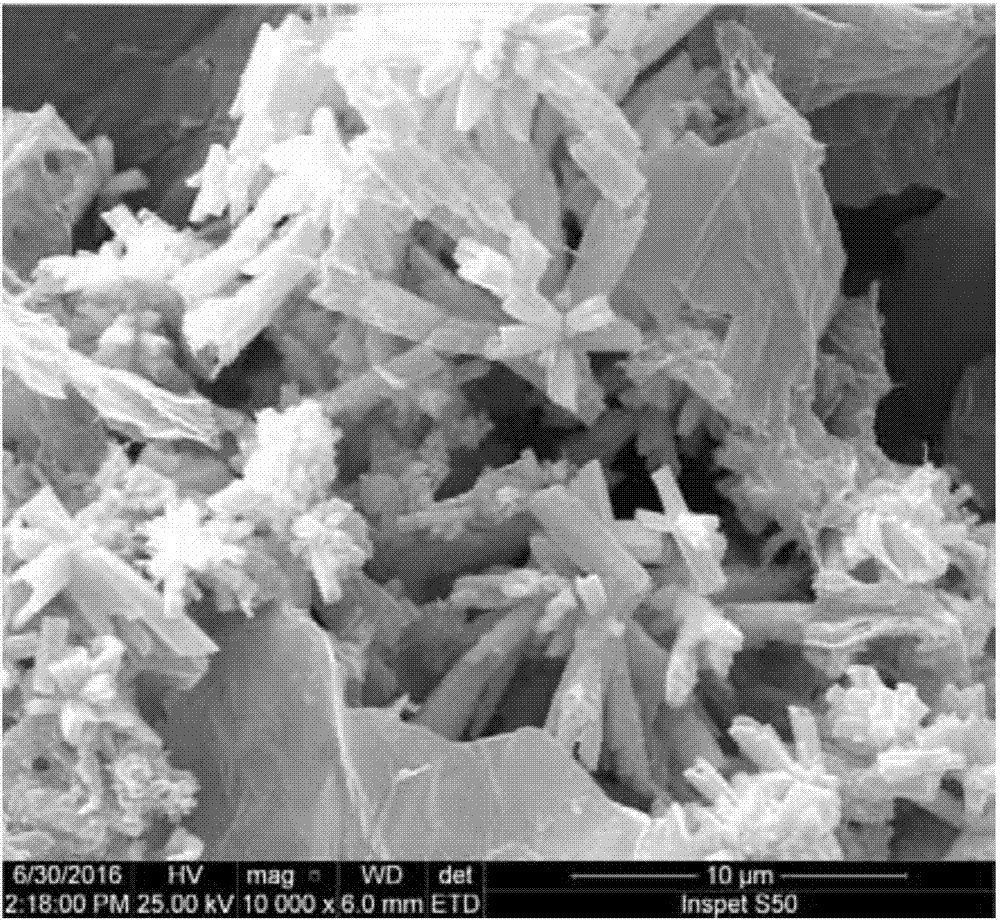

[0024] Specific embodiment one: the preparation method of a kind of tubular tungsten oxide-graphene composite material of this embodiment is carried out according to the following steps:

[0025] One, the graphite powder is oxidized by the improved Hummers method to obtain graphite oxide powder;

[0026] 2. Ultrasonic disperse the graphite oxide powder obtained in step 1 in n-propanol, the ultrasonic frequency is 35kHz-45kHz, and the ultrasonic time is 0.5h-1.5h to obtain a dispersion solution, and then add tungsten hexachloride to the dispersion solution, wait After the tungsten hexachloride is completely dissolved, transfer the solution into the reactor for hydrothermal reaction to obtain a mixed solution; wherein the hydrothermal reaction temperature is 150-250°C, and the hydrothermal reaction time is 10h-14h;

[0027] The mass ratio of graphite oxide powder described in step 2 to n-propanol is 1 mg to 5 mg: 3 mL;

[0028] The volume ratio of the amount of tungsten hexachl...

specific Embodiment approach 2

[0031] Specific embodiment two: what this embodiment is different from specific embodiment one is: the specific process that the improved Hummers method is carried out oxidation to graphite in the step one is: 1. graphite powder is mixed with sodium nitrate, then add the concentrated sulfuric acid, stir in ice bath 1h, mixed solution A is obtained; the mass ratio of the graphite powder to sodium nitrate is 5:1.5; the mass ratio of the graphite powder to the concentrated sulfuric acid is 2g:67.5mL; Add potassium permanganate at a rate of 9g / h in the mixed solution A, continue the ice bath for 2h, then transfer to a water bath, and react for 120h at room temperature to obtain mixed solution B; the potassium permanganate and step 1. The mass ratio of described graphite powder is 9:2; 3. add the sulfuric acid that mass fraction is 5% in the mixed solution B that step 2. obtains, stir 2h, obtain mixed solution C; Described mass fraction is the sulfuric acid of 5% and step The volum...

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 to Embodiment 2 in that the volume ratio of the graphite oxide powder described in step 2 to n-propanol is 1 mg: 1 mL. Other steps and parameters are the same as those in the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com