Preparation method of WO3 nano-sheet array

A nanosheet array and substrate material technology, applied in the field of photocatalysis and photoelectrochemical materials, can solve the problems of low crystallinity, complicated operation process, and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

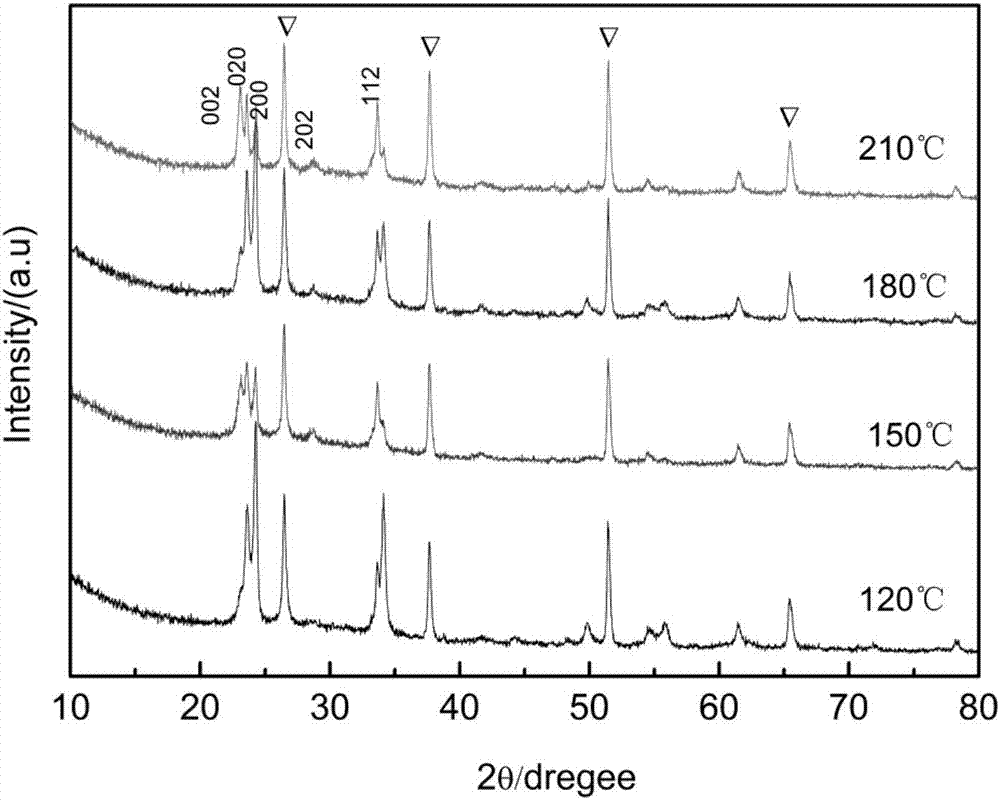

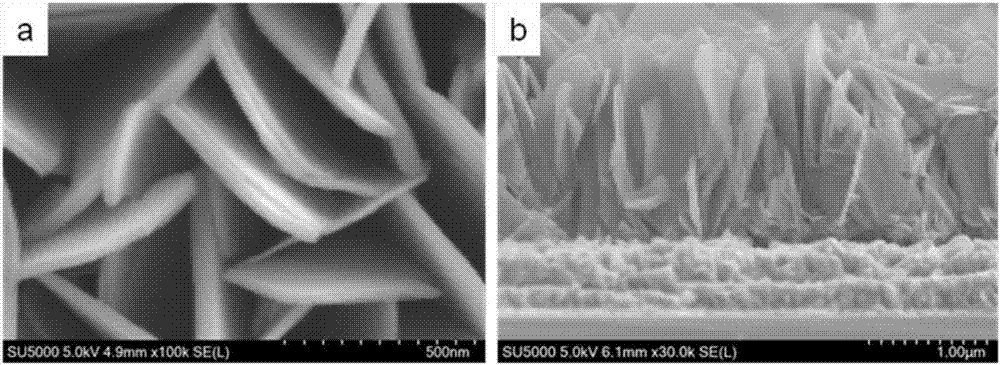

[0014] (1) Dissolve 0.4 g of oxalic acid in 40 mL of absolute ethanol, and weigh 0.2 g of tungsten hexachloride in a vacuum glove box. After mixing evenly, add it into a polytetrafluoroethylene reaction kettle with a volume of 60mL, then put the cleaned FTO into the polytetrafluoroethylene reaction kettle obliquely, react at 180°C for 6 hours, cool the reaction kettle with tap water for 30 minutes, and wash it with distilled water The surface of the FTO was vacuum-dried at 60°C for use.

[0015] (2) Put the electrode material synthesized in step (1) into a muffle furnace, raise the temperature to 500°C at a heating rate of 5°C / min, anneal for 120min, take it out after it drops to room temperature, and obtain the FTO surface with WO 3 Photoelectrodes of nanosheet arrays.

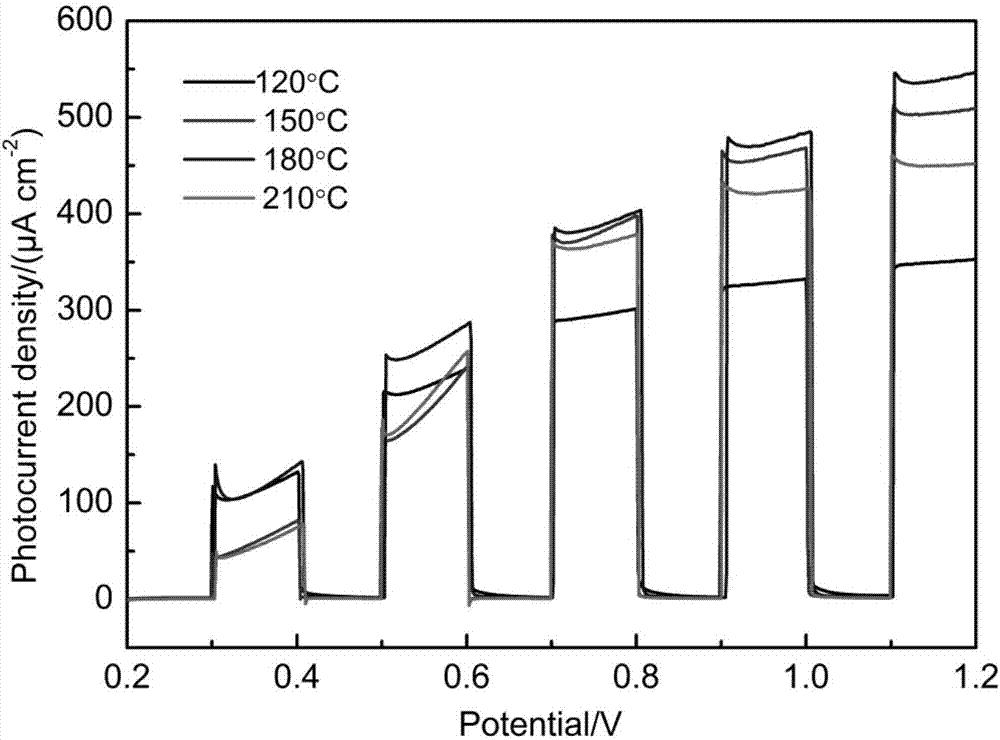

[0016] With the prepared WO 3 The nanosheet array photoelectrode was used as the working electrode (with an area of 1 cm 2 ), the auxiliary electrode is a platinum electrode, the saturated calomel electr...

Embodiment 2

[0018] (1) Dissolve 0.4 g of oxalic acid in 40 mL of absolute ethanol, and weigh 0.2 g of tungsten hexachloride in a vacuum glove box. After mixing evenly, add it to a polytetrafluoroethylene reaction kettle with a volume of 60mL, then put the cleaned carbon cloth into the polytetrafluoroethylene reaction kettle, react at 120°C for 6h, cool with tap water for 30min, and clean the surface of the carbon cloth with distilled water , vacuum-dried at 60°C and set aside.

[0019] (2) Put the electrode material synthesized in step (1) into a muffle furnace, raise the temperature to 400°C at a heating rate of 5°C / min, anneal for 120min, take it out after it drops to room temperature, and obtain carbon cloth substrate surface with WO 3 Photoelectrodes of nanosheet arrays.

[0020] WO 3 Nanosheet array carbon cloth as the working electrode (with an area of 1 cm 2 ), the auxiliary electrode is a platinum electrode, the saturated calomel electrode (SCE) is used as a reference electr...

Embodiment 3

[0022] 1) Dissolve 0.8g of oxalic acid in 40mL of absolute ethanol, and weigh 0.2g of tungsten hexachloride in a vacuum glove box. After mixing evenly, add it to a polytetrafluoroethylene reaction kettle with a volume of 60mL, then put the cleaned silicon chip into the polytetrafluoroethylene reaction kettle obliquely, react at 180°C for 6h, cool with tap water for 30min, and wash the silicon wafer with distilled water. The surface of the sheet was vacuum-dried at 60°C for use.

[0023] (2) Put the electrode material synthesized in step (1) into a muffle furnace, raise the temperature to 600°C at a heating rate of 5°C / min, anneal for 120min, take it out after it drops to room temperature, and obtain a substrate with WO 3 Photoelectrodes of nanosheet arrays.

[0024] WO 3 Nanosheet array carbon cloth as the working electrode (with an area of 1 cm 2 ), the auxiliary electrode is a platinum electrode, the saturated calomel electrode (SCE) is used as a reference electrode, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com