Nano grass composite photoelectric material for photoelectrochemical cathode protection and preparation and application of nano grass composite photoelectric material

A photoelectric material and cathodic protection technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as easy compounding, limited photoelectric performance, narrow spectral response range, etc., to achieve large light capture area, good Improvement of transmission performance and photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

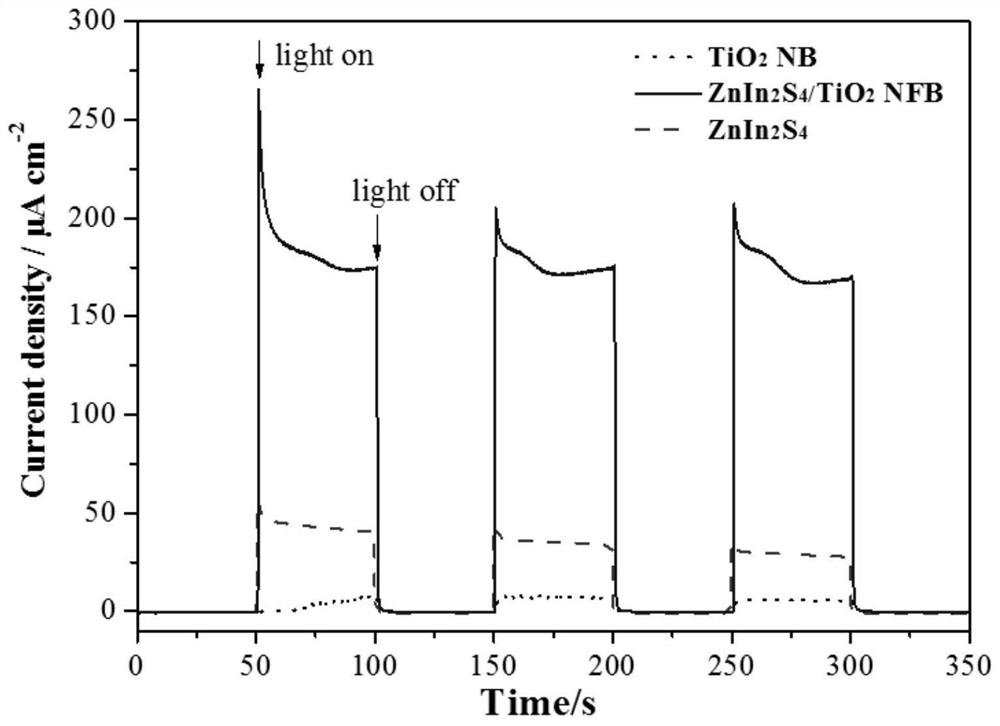

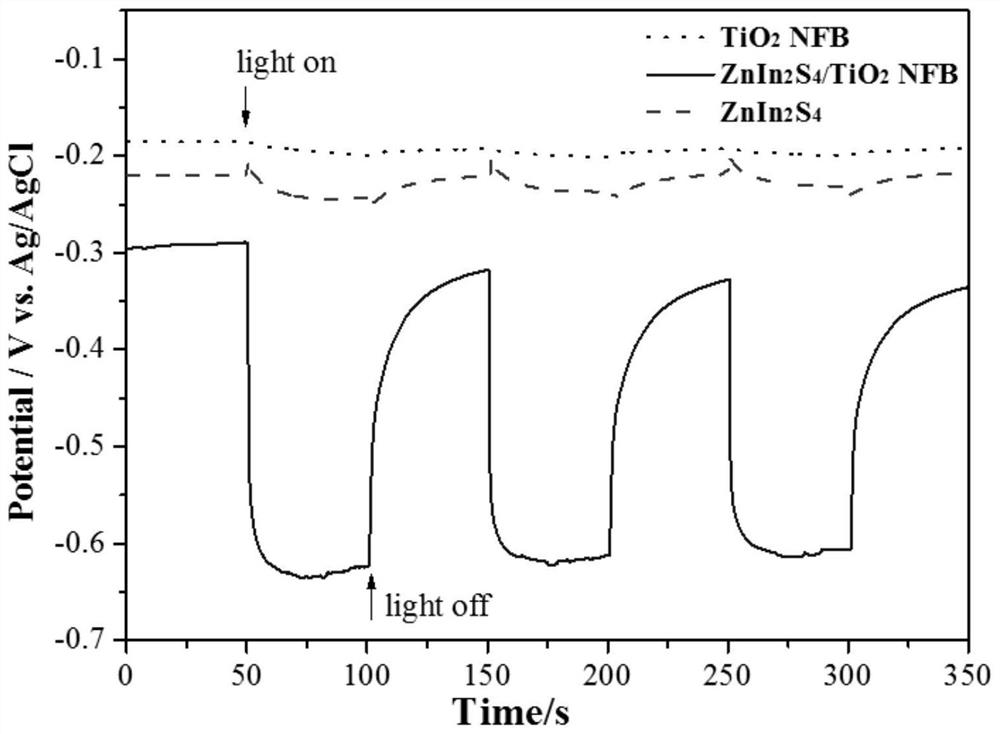

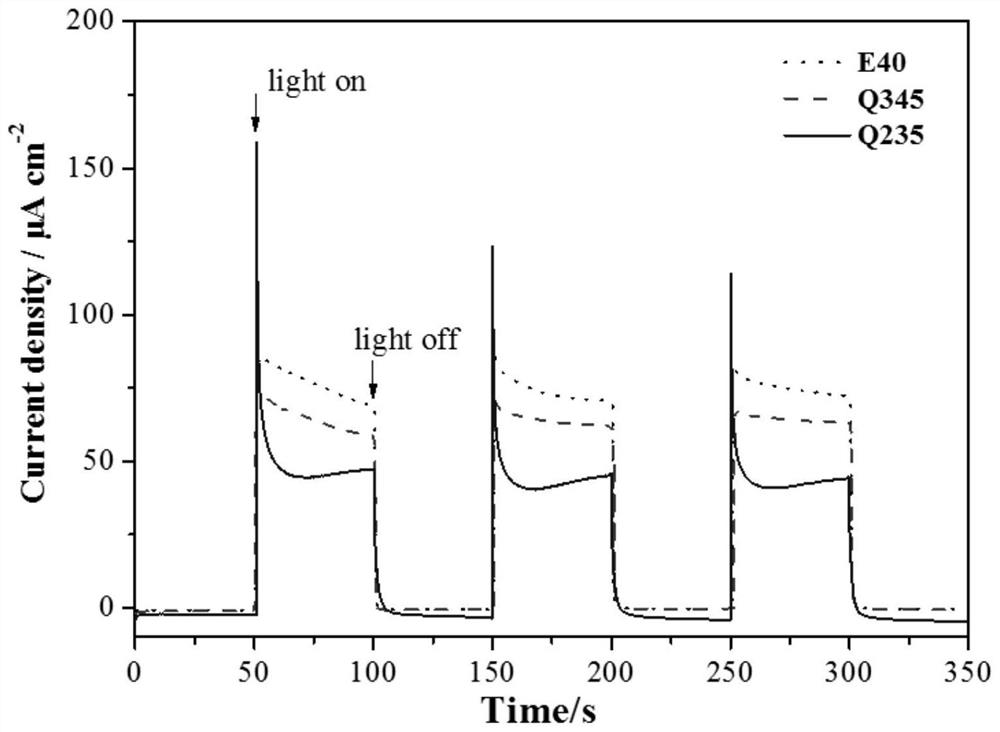

[0038] ZnIn for Photoelectrochemical Cathodic Protection 2 S 4 / TiO 2 Preparation of nanograss composite optoelectronic materials:

[0039] 1) Preparation of FTO conductive glass: first cut the FTO glass into 20×10mm 2 size, and then ultrasonically cleaned in analytical grade acetone for 5 minutes, and then cleaned in deionized water for 5 minutes, and then the FTO glass was dried for use.

[0040] 2) TiO 2 Preparation of the nanograss substrate: place the FTO conductive glass treated in step 1) in the liner of the autoclave, with the conductive side facing down and at an angle of 45° to the wall of the autoclave, and add solution a into the autoclave to immerse the glass substrate material, and then heated in water at 180°C for 9 hours. After the hydrothermal treatment, the FTO glass was taken out, rinsed repeatedly with deionized water and dried, and then annealed at 450 °C for 1 hour to obtain TiO 2 Nanograss film substrate (see figure 1 a and b). Among them, soluti...

Embodiment 2

[0051] ZnIn for Photoelectrochemical Cathodic Protection 2 S 4 / TiO 2 Preparation of nanograss composite optoelectronic materials:

[0052] 1) Preparation of FTO conductive glass: first cut the FTO glass into 20×10mm 2 size, and then ultrasonically cleaned in analytical grade acetone for 5 minutes, and then cleaned in deionized water for 5 minutes, and then the FTO glass was dried for use.

[0053] 2) TiO 2 Preparation of the nanograss substrate: place the FTO conductive glass treated in step 1) in the liner of the autoclave, with the conductive side facing down and at an angle of 45° to the wall of the autoclave, and add solution a into the autoclave to immerse the glass substrate material, and then heated in water at 180°C for 9 hours. After the hydrothermal treatment, the FTO glass was taken out, rinsed repeatedly with deionized water and dried, and then annealed at 450 °C for 1 hour to obtain TiO 2 Nanograss film substrate. Among them, solution a is a solution in wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com