Preparation method and application of modified material based on titanium dioxide

A technology of titanium dioxide and modified materials, applied in the field of materials, can solve the problems of limited light absorption range and slow charge transfer kinetics, and achieve the effects of broadening the light absorption range, improving efficiency and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

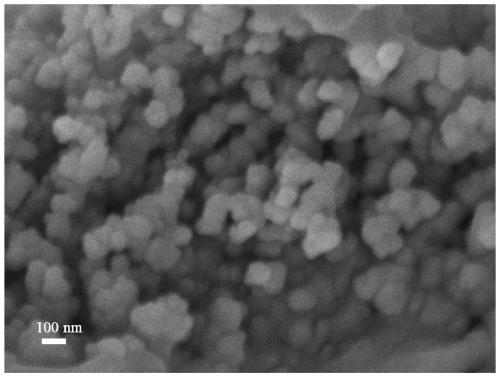

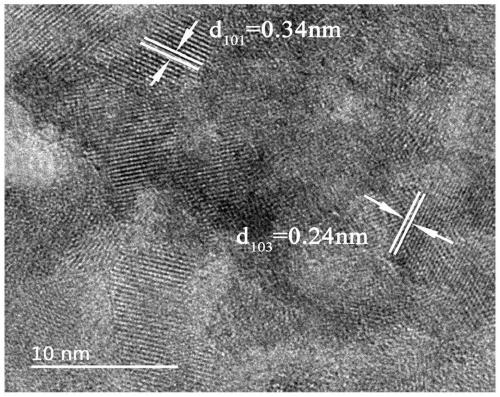

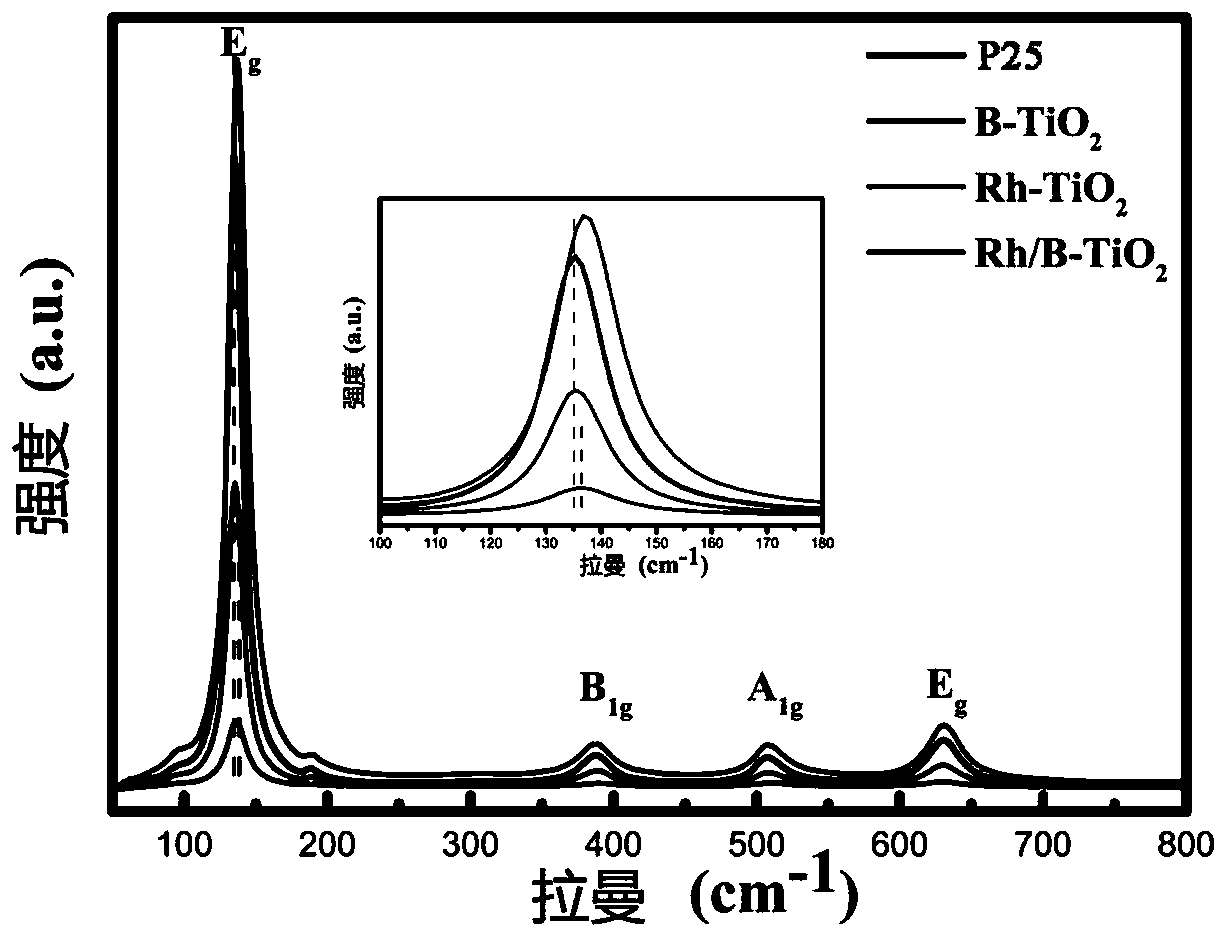

[0025] The invention provides a preparation method based on titanium dioxide modified material, specifically comprising the following steps:

[0026] Step 1, dissolving a certain amount of boric acid and rhodium chloride trihydrate in a mixed solution of alcohol and water containing a certain amount of nitric acid, and mixing evenly to obtain liquid A. Wherein, the molar ratio of boric acid to rhodium chloride trihydrate is 50:1~5:1, the molar ratio of nitric acid, alcohol and water is 0.1:1:1~0.1:4:1, and the alcohol can be methanol or ethanol. In the embodiment of the present invention, ethanol is used, and in practical application, using methanol can achieve the same technical effect as ethanol.

[0027] Step 2, in a dry environment, under the condition of 0°C to 4°C, add isopropyl titanate dropwise into the ethanol solution to obtain liquid B. Wherein, the molar ratio of boric acid to isopropyl titanate is 5:1-20:1, and the reaction temperature is controlled at 0-4°C. I...

Embodiment 1

[0033] This example prepares a modified material based on titanium dioxide, the molar ratio of isopropyl titanate, boric acid and rhodium chloride trihydrate is selected as 500:50:1, and the specific operation is as follows:

[0034] Step 1: Dissolve boric acid and rhodium chloride trihydrate in a mixed solution of ethanol and water containing a certain amount of nitric acid (the molar ratio of nitric acid, ethanol and water is 0.1:1:1), and mix evenly to obtain liquid A.

[0035] Step 2, in a dry environment, under the condition of 0°C to 4°C, add isopropyl titanate dropwise into the ethanol solution to obtain liquid B. Control the reaction temperature to maintain it at 0-4°C. In this step, the isopropyl titanate is partially hydrolyzed, that is, the system is slightly turbid during the dropping process, but no obvious white precipitate appears, and the finally obtained liquid B is a translucent suspension.

[0036] Step 3, slowly drop the liquid A into the liquid B, continu...

Embodiment 2

[0040]This example prepares a modified material based on titanium dioxide, the molar ratio of isopropyl titanate, boric acid and rhodium chloride trihydrate is selected as 500:50:5, and the specific operation is as follows:

[0041] Step 1: Dissolve boric acid and rhodium chloride trihydrate in a mixed solution of ethanol and water containing a certain amount of nitric acid (the molar ratio of nitric acid, ethanol and water is 0.1:2:1), and mix evenly to obtain liquid A.

[0042] Step 2, in a dry environment, under the condition of 0°C to 4°C, add isopropyl titanate dropwise into the ethanol solution to obtain liquid B. Control the reaction temperature to maintain it at 0-4°C. In this step, the isopropyl titanate is partially hydrolyzed, that is, the system is slightly turbid during the dropping process, but no obvious white precipitate appears, and the finally obtained liquid B is a translucent suspension.

[0043] Step 3, slowly drop the liquid A into the liquid B, continuo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com