Method for preparing hydrogen peroxide by using enol-ketone type covalent organic framework/graphite phase carbon nitride composite photocatalyst

A graphitic carbon nitride, covalent organic framework technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve structural dissociation, poor crystallinity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing hydrogen peroxide by using enol-ketone covalent organic framework / graphite phase carbon nitride composite photocatalyst, comprising the following steps:

[0045] Take enol-ketone covalent organic framework / graphite phase carbon nitride composite photocatalyst (1%TpMa / CN, 5%TpMa / CN, 15%TpMa / CN, 25%TpMa / CN), carbon nitride photocatalyst (CN), each 100mg, and they are respectively added to 100mL, the volume concentration is 10% isopropanol aqueous solution (this isopropanol aqueous solution is the mixed solution of isopropanol and ultrapure water, wherein isopropanol and ultrapure water The volume ratio of water is 1:9), stir magnetically in a dark place (i.e. under dark conditions) for one hour, turn on the light source after reaching adsorption equilibrium, and carry out photocatalytic reaction under visible light (λ≥420nm) for 60min to obtain hydrogen peroxide .

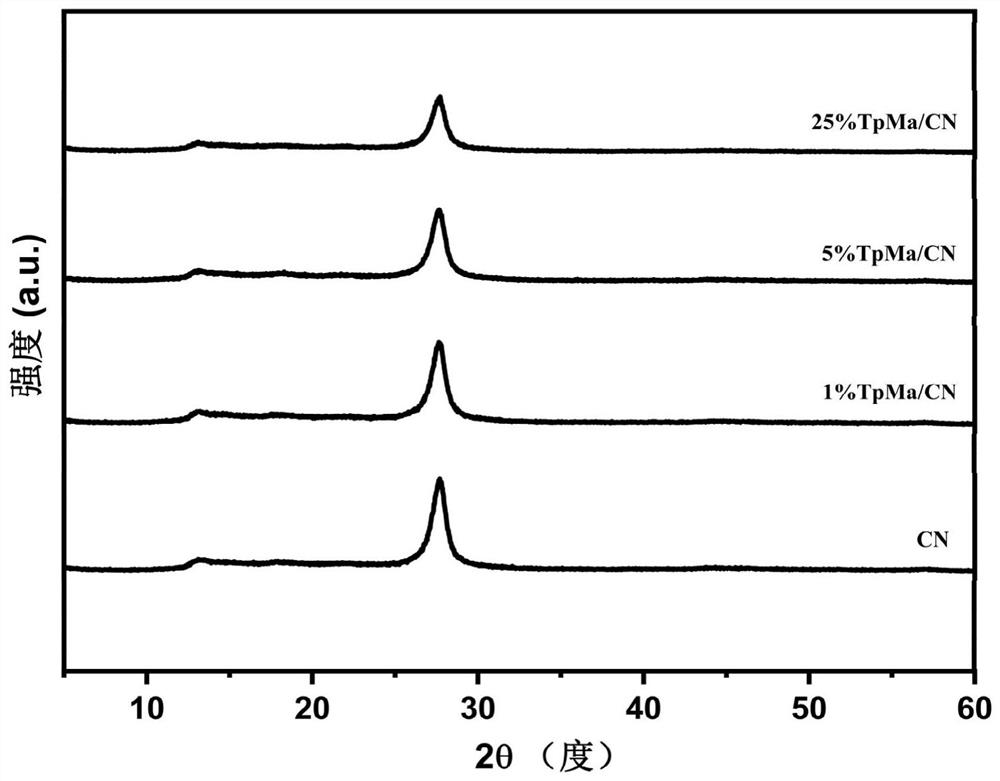

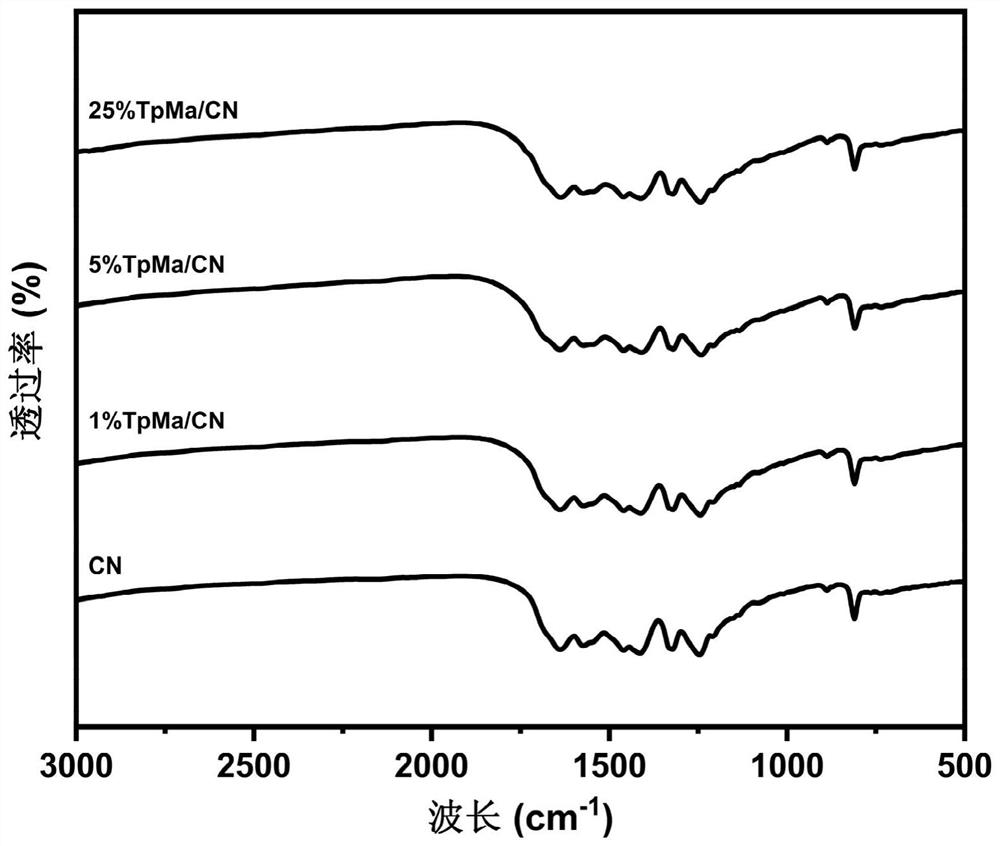

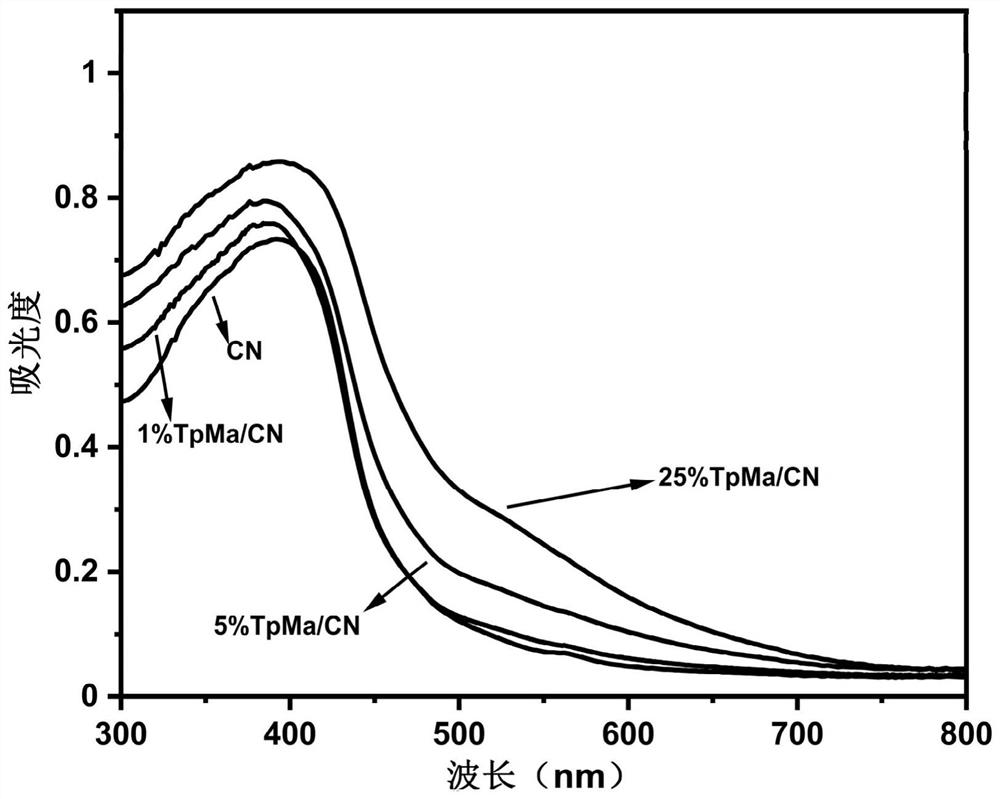

[0046] In this embodiment, the enol-ketone covalent organic framework / graphite phas...

Embodiment 2

[0069] To investigate the reusability of enol-ketone covalent organic framework / graphite carbon nitride composite photocatalyst in the photocatalytic production of hydrogen peroxide, including the following steps:

[0070] (1) Weigh 100 mg of the enol-ketone covalent organic framework / graphite phase carbon nitride composite photocatalyst (5% TpMa / CN) prepared in Example 1, add to 100 mL, 10% volume concentration of isopropyl Alcohol aqueous solution to obtain the reaction system.

[0071] (2) Place the reaction system (isopropanol solution with 5% TpMa / CN added) obtained in step (1) on a magnetic stirrer, and stir for 1 h in the dark to achieve adsorption equilibrium, and take 3 mL of the solution to represent the The initial solution of the reaction, that is, the solution when the reaction time is 0min, after filtration and color development, its concentration is measured with a UV-visible spectrophotometer, and converted into yield.

[0072] (3) The remaining solution of st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com