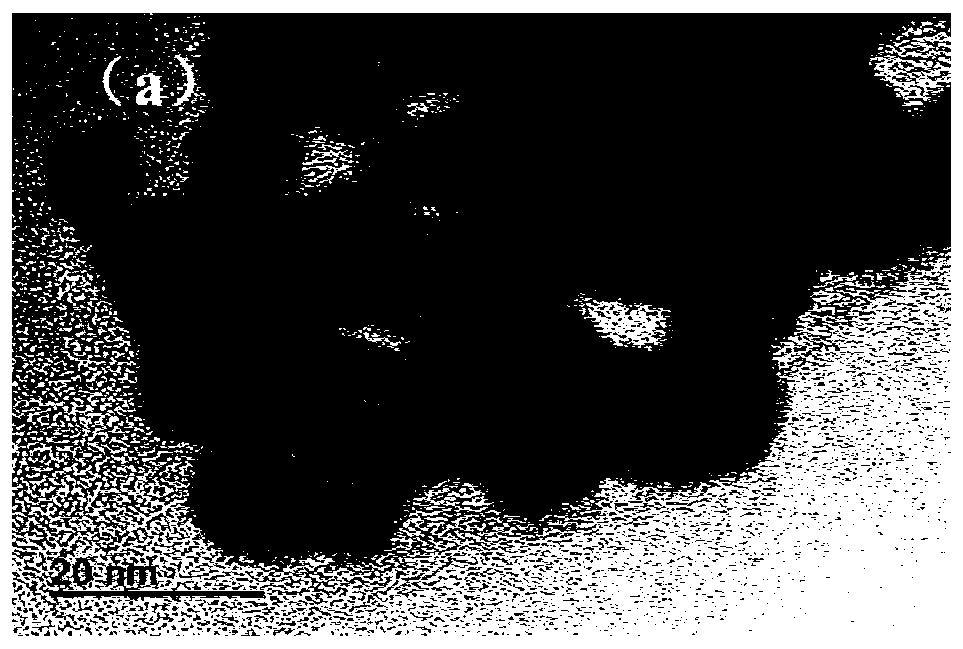

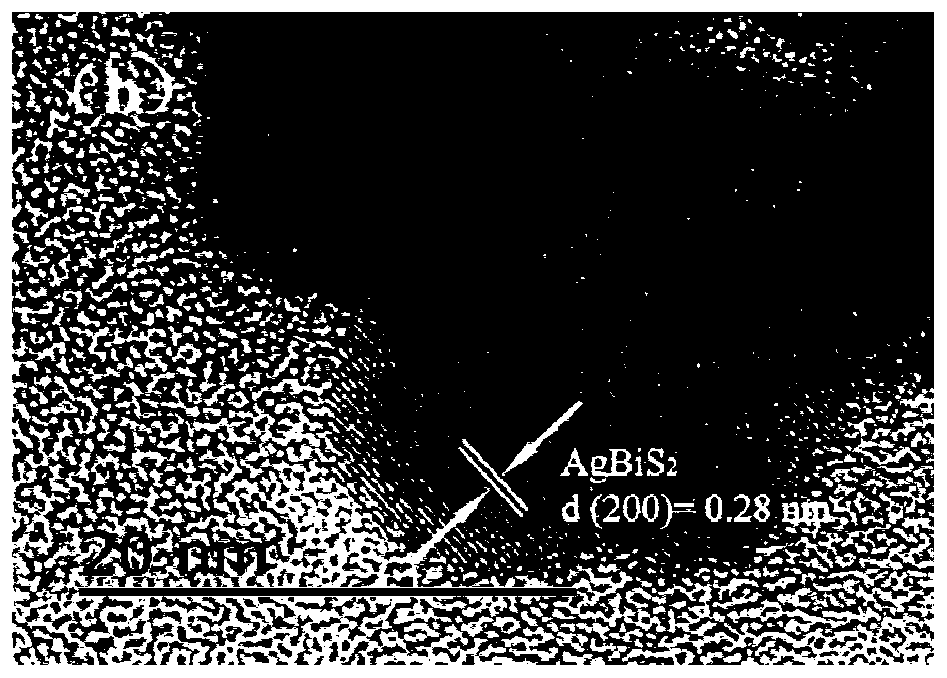

Semiconductor photosensitizer AgBiS2 quantum dot and preparation method thereof

A photosensitizer and semiconductor technology, applied in the nanometer field, can solve the problems of uncontrollable quantum dot size, narrow photoresponse range, and many surface defects, and achieve the effect of excellent photoresponse ability, good crystallinity, and few surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A semiconductor photosensitizer AgBiS 2 Quantum dots and methods for their preparation. The specific steps of the preparation method described in this embodiment are:

[0023] Step 1, containing Ag + and Bi 3+ Preparation of the Mixed Precursor Solution

[0024] According to silver salt: the ratio of the amount of substance of bismuth salt is 1: (1~2), described silver salt and described bismuth salt are mixed, obtain mixture; Then be 0.19~0.21mol / L according to concentration, the obtained The mixture is mixed with oleylamine, and stirred for 2-3 hours under the conditions of nitrogen atmosphere, 100-120°C and 500-800r / min to obtain Ag-containing + and Bi 3+ mixed precursor solution.

[0025] Step 2, the preparation of the precursor solution of sulfur

[0026] According to the concentration of 0.39~0.41mol / L, mix the sublimated sulfur and 1-octadecene, and then stir for 2~3h under the conditions of nitrogen atmosphere, 100~120℃ and 500~800r / min to prepare the pre...

Embodiment 2

[0032] A semiconductor photosensitizer AgBiS 2 Quantum dots and methods for their preparation. The specific steps of the preparation method described in this embodiment are:

[0033] Step 1, containing Ag + and Bi 3+ Preparation of the Mixed Precursor Solution

[0034] According to silver salt: the ratio of the amount of substance of bismuth salt is 1: (2~3), described silver salt and described bismuth salt are mixed, obtain mixed material; Then be 0.19~0.21mol / L according to concentration, the obtained The mixture is mixed with oleylamine, and stirred for 2-3 hours under the conditions of nitrogen atmosphere, 100-120°C and 500-800r / min to obtain Ag-containing + and Bi 3+ mixed precursor solution.

[0035] Step 2, the preparation of the precursor solution of sulfur

[0036]According to the concentration of 0.39~0.41mol / L, mix the sublimated sulfur and 1-octadecene, and then stir for 2~3h under the conditions of nitrogen atmosphere, 100~120℃ and 500~800r / min to prepare t...

Embodiment 3

[0042] A semiconductor photosensitizer AgBiS 2 Quantum dots and methods for their preparation. The specific steps of the preparation method described in this embodiment are:

[0043] Step 1, containing Ag + and Bi 3+ Preparation of the Mixed Precursor Solution

[0044] According to silver salt: the ratio of the amount of substance of bismuth salt is 1: (3~4), described silver salt and described bismuth salt are mixed, obtain mixture; Then be 0.19~0.21mol / L according to concentration, the obtained The mixture is mixed with oleylamine, and stirred for 2-3 hours under the conditions of nitrogen atmosphere, 100-120°C and 500-800r / min to obtain Ag-containing + and Bi 3+ mixed precursor solution.

[0045] Step 2, the preparation of the precursor solution of sulfur

[0046] According to the concentration of 0.39~0.41mol / L, mix the sublimated sulfur and 1-octadecene, and then stir for 2~3h under the conditions of nitrogen atmosphere, 100~120℃ and 500~800r / min to prepare the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com