Mo-doped MoO3@ZnIn2S4 Z system photocatalyst as well as preparation method and application thereof

A photocatalyst and system technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of hindered kinetic process of hydrogen production, achieve excellent photocatalytic performance, rich raw material sources, Avoid the effects of cocatalyst modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

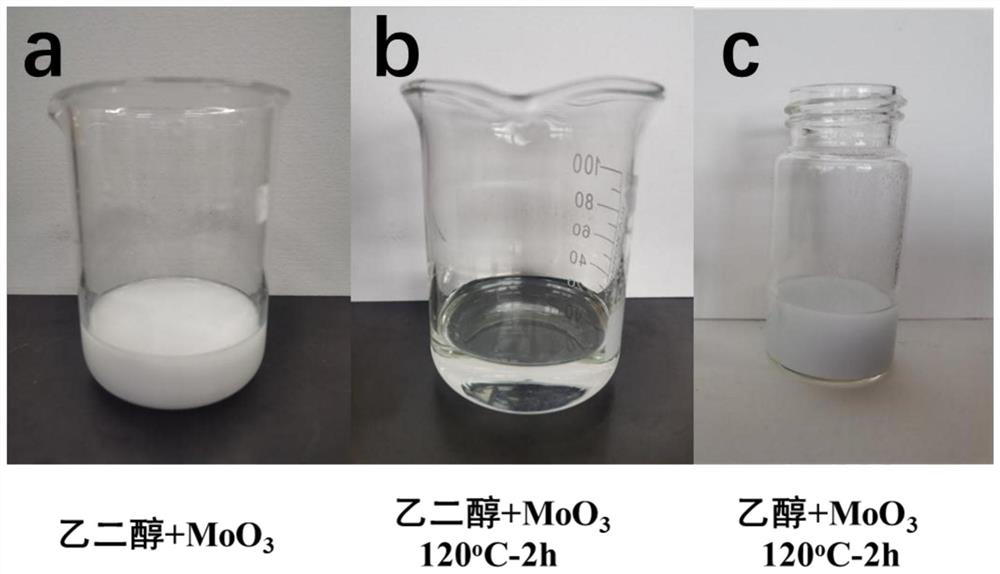

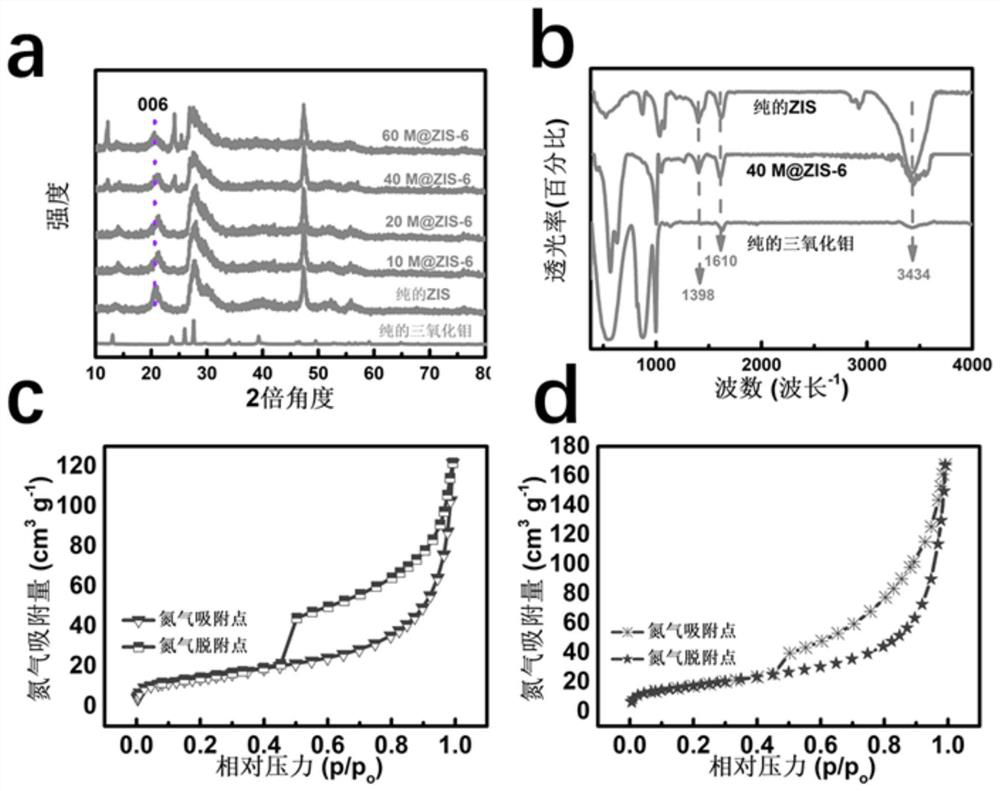

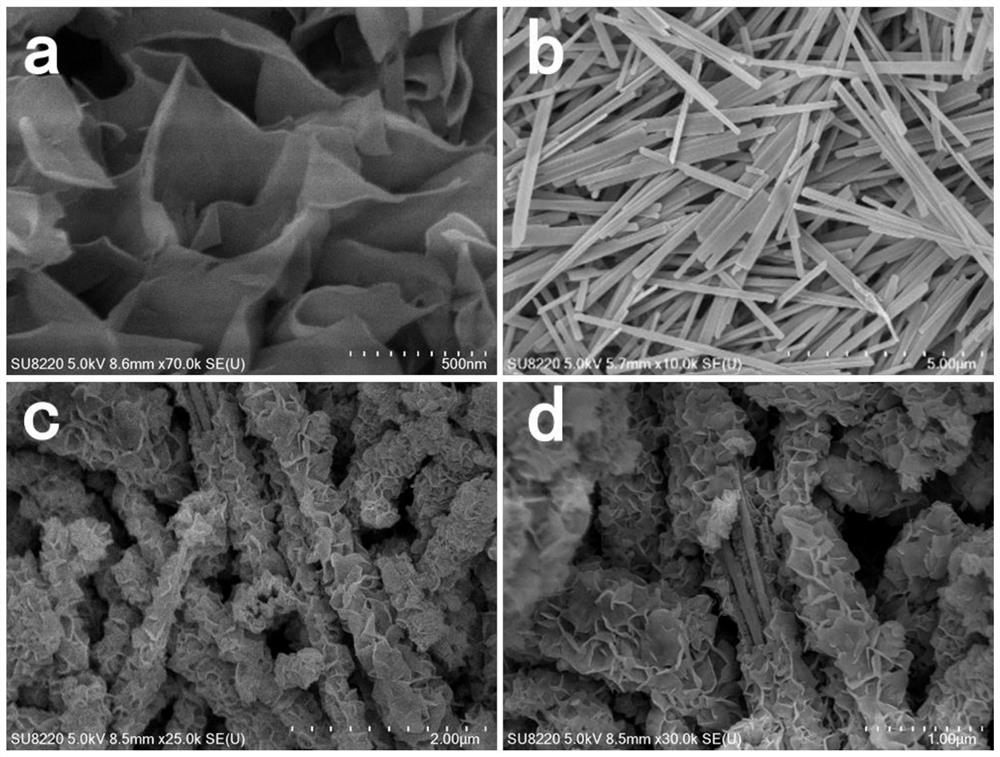

[0042] The preparation process of the present invention is as follows:

[0043] Synthesis of MoO via a hydrothermal process 3 nanorods, the MoO 3 Add nanorods (10-60mg) into 20ml of ethylene glycol solvent and sonicate for 30 minutes, then dissolve zinc source, indium chloride tetrahydrate, and thioacetamide in the above ethylene glycol solution at a mass ratio of 136:586:300 , stirred evenly for 30 minutes and transferred to a high-pressure reactor, kept at 120°C for 2-12 hours, cooled to room temperature naturally, the obtained product was washed with absolute ethanol, and vacuum-dried to obtain MoO doped with different Mo 3 @ZnIn 2 S 4 The Z system photocatalyst is named x-M@ZIS-y (x: the amount of molybdenum oxide added; y: the reaction time).

Embodiment 1

[0049] Dissolve 1.4g of ammonium molybdate tetrahydrate in 40mL of acid solution (33mL of water + 7mL of concentrated nitric acid), stir evenly, transfer to a high-pressure reactor, keep warm at 180°C for 24h, and naturally cool to room temperature. and absolute ethanol were washed three times each, and MoO was obtained after vacuum drying. 3 Nano stave. 10mg MoO 3 Disperse the nanorods in 20mL of ethylene glycol and sonicate for 30min; dissolve anhydrous zinc chloride, indium chloride tetrahydrate, and thioacetamide in the above ethylene glycol solution at a mass ratio of 136:586:300, and stir evenly 30min and transferred to an autoclave, kept at 120°C for 2h, cooled to room temperature naturally, the product obtained was centrifuged and washed three times with absolute ethanol, and dried in vacuum to obtain Mo-doped MoO 3 @ZnIn 2 S 4 Z system photocatalyst named 10-M@ZIS-2.

Embodiment 2

[0051] Dissolve 1.4g of ammonium molybdate tetrahydrate in 40mL of acid solution (33mL of water + 7mL of concentrated nitric acid), stir evenly, transfer to a high-pressure reactor, keep warm at 180°C for 24h, and naturally cool to room temperature. and absolute ethanol were washed three times each, and MoO was obtained after vacuum drying. 3 Nano stave. 20mg MoO 3 Disperse the nanorods in 20mL of ethylene glycol and sonicate for 30min, dissolve anhydrous zinc chloride, indium chloride tetrahydrate, and thioacetamide in the above ethylene glycol solution at a mass ratio of 136:586:300, and stir evenly 30min and transferred to an autoclave, kept at 120°C for 2h, cooled to room temperature naturally, washed three times with absolute ethanol, and dried in vacuum to obtain Mo-doped MoO 3 @ZnIn 2 S 4 Z system photocatalyst named 20-M@ZIS-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com