Graphite-phase carbon nitride film and preparation method thereof

A graphite phase carbon nitride, thin film technology, applied in vacuum evaporation plating, coating, sputtering plating and other directions, can solve the problems of poor controllability of the evaporation process, improve photoelectric and photoelectrochemical performance, good uniformity , to improve the effect of the conduction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

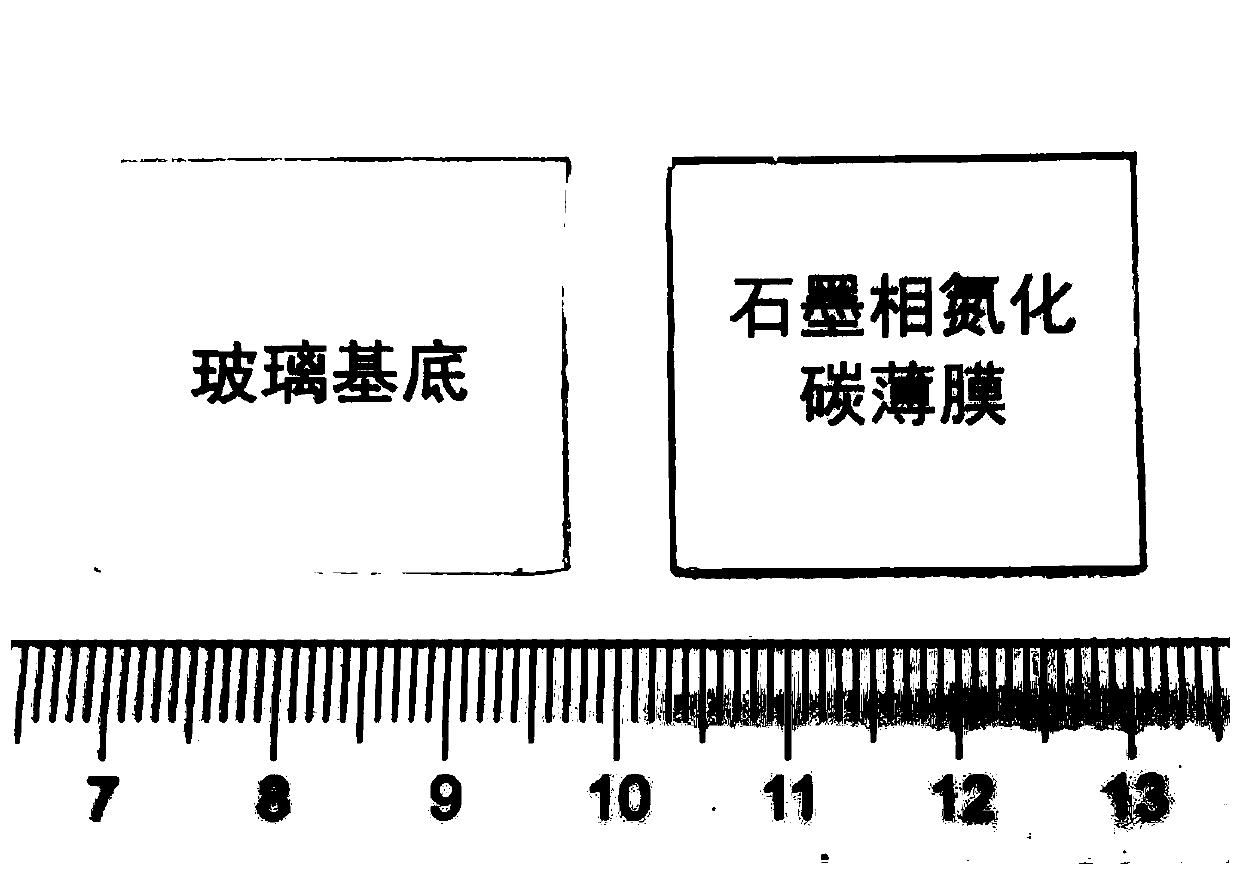

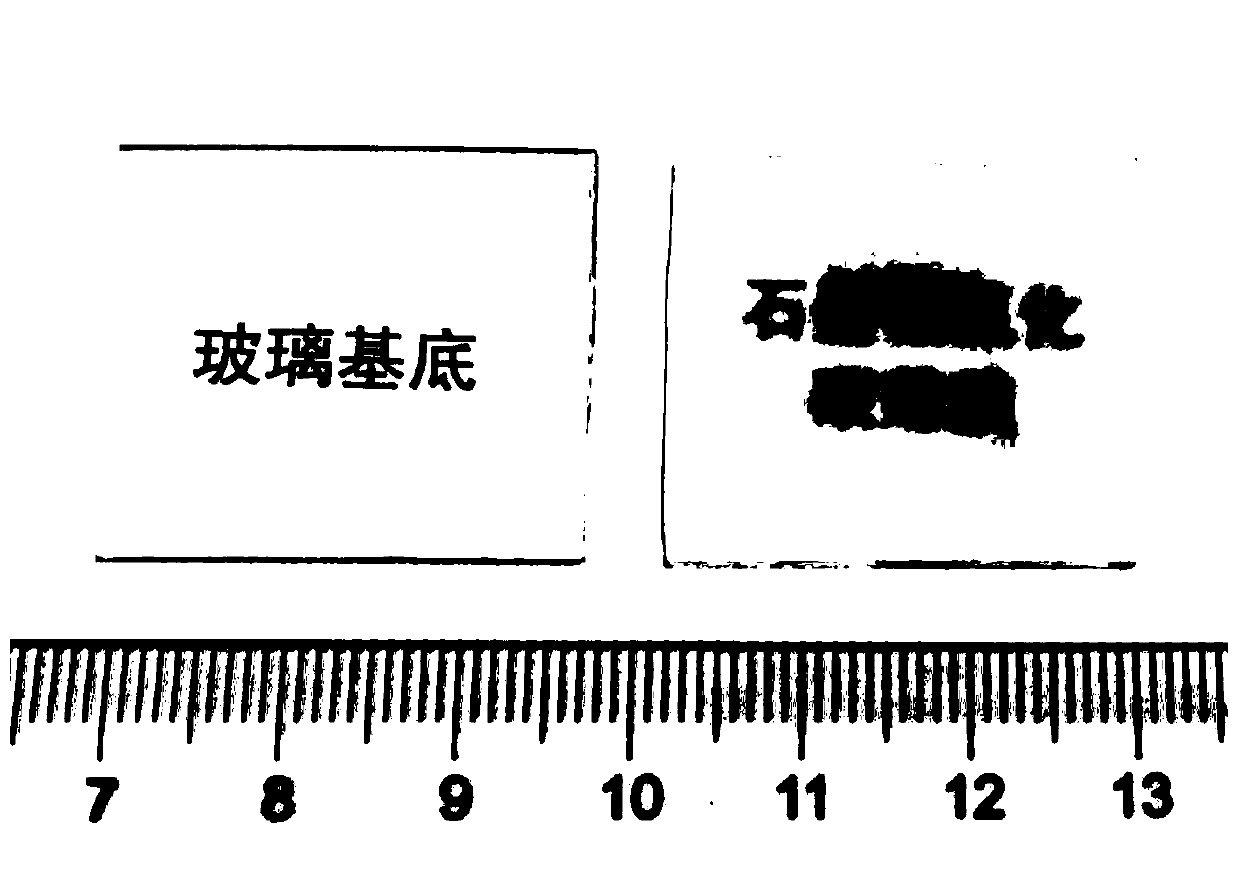

[0045] This embodiment provides a graphite phase carbon nitride film, the preparation method of which comprises:

[0046]Weigh 10g of melamine, load it into an open quartz boat, and place it in the center of the tube furnace; raise the temperature to 350°C under a flowing nitrogen atmosphere, with a heating rate of 10°C / min, and keep it warm for 1 hour; after the initial pyrolysis and polycondensation , naturally cooled to room temperature, and the pyrolysis product was ground into a powder sample; the above powder was loaded into a quartz boat, and the cleaned glass substrate was covered on the quartz boat and placed in the central position of the tube furnace. Under a nitrogen atmosphere, the temperature was raised to 550° C. at a heating rate of 10° C. / min, kept for 4 hours, and finally cooled to room temperature to obtain a graphite phase carbon nitride film with a thickness of about 430 nm.

Embodiment 2

[0048] This embodiment provides a graphite phase carbon nitride film, the preparation method of which comprises:

[0049] Weigh 10g of melamine, load it into an open quartz crucible, and place it in the center of the tube furnace; raise the temperature to 350°C under a flowing nitrogen atmosphere, with a heating rate of 10°C / min, and keep it warm for 1 hour; after the initial pyrolysis and polycondensation , naturally cooled to room temperature, and the pyrolysis product was ground into a powder sample; the above powder was put into a quartz crucible, and the quartz crucible was covered with a cleaned quartz glass substrate and placed in the central position of the tube furnace. Under a flowing nitrogen atmosphere, the temperature was raised to 550° C. at a heating rate of 10° C. / min, kept for 4 hours, and finally cooled to room temperature to obtain a graphite phase carbon nitride film with a thickness of about 310 nm.

Embodiment 3

[0051] This embodiment provides a graphite phase carbon nitride film, the preparation method of which comprises:

[0052] Weigh 10g of melamine and load it into an open quartz boat, and place it in the center of the tube furnace; raise the temperature to 350°C in an air atmosphere, with a heating rate of 10°C / min, and keep it warm for 1 hour; after the initial pyrolysis and polycondensation, Naturally cool to room temperature, grind the pyrolysis product into a powder sample; put the above powder into a quartz boat, cover the cleaned glass substrate on the quartz boat and place it in the central position of the tube furnace, in the air atmosphere The temperature was raised to 550° C. at a heating rate of 5° C. / min, kept for 6 hours, and finally cooled to room temperature to obtain a graphite phase carbon nitride film with a thickness of about 340 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com