Molecular imprinting photoelectrochemical sensor as well as preparation method and application thereof

A molecular imprinting and photoelectrochemical technology, applied in the fields of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of low detection sensitivity of photoelectrochemical sensing, cumbersome pretreatment steps, expensive instruments and equipment, etc. The effect of improving photoelectrochemical performance and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

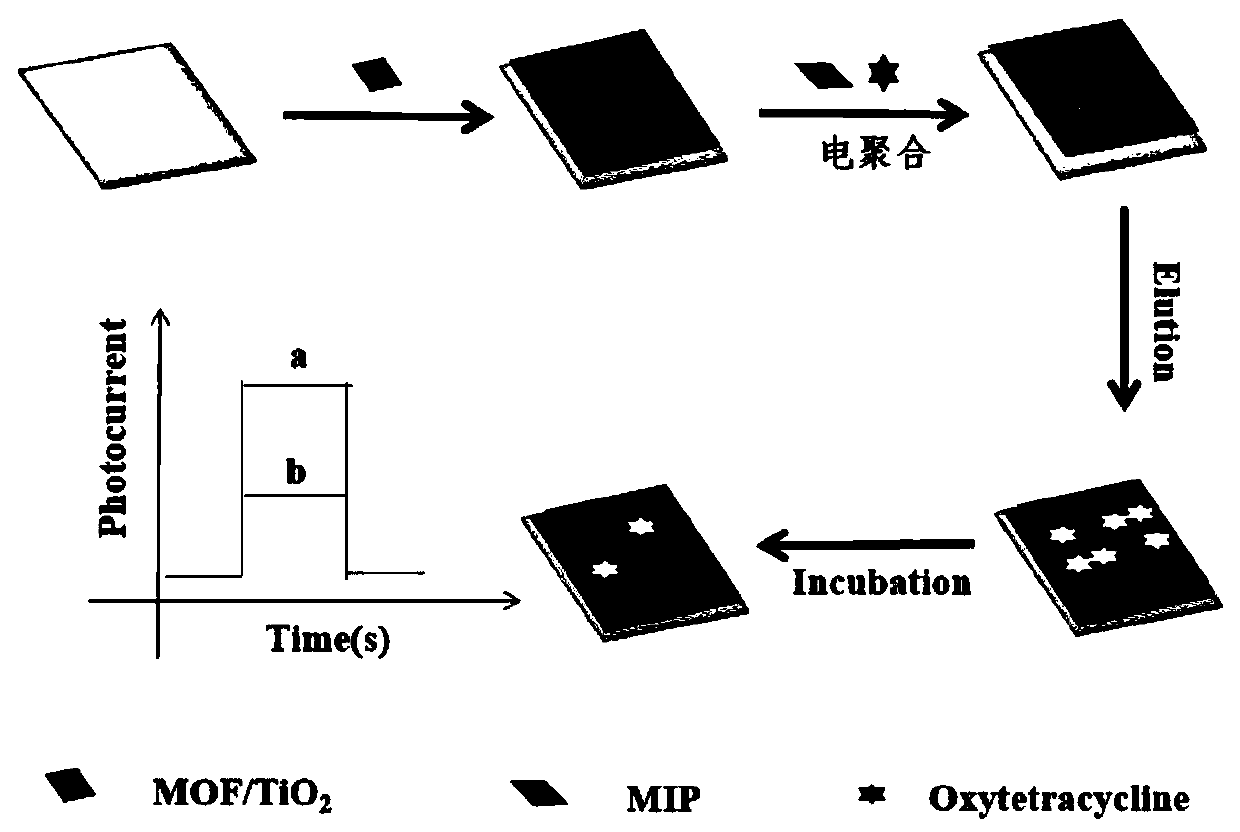

[0033] A MIL-125-NH based 2 / TiO 2 Molecularly imprinted photoelectrochemical sensor of composite material, including working electrode, and MIL-125-NH sequentially modified on the surface of the working electrode 2 / TiO 2 The photoelectric conversion layer and the molecular imprinted film layer, the working electrode is an indium tin oxide electrode (ITO).

Embodiment 2

[0035] A MIL-125-NH based 2 / TiO 2 A method for preparing a molecularly imprinted photoelectrochemical sensor of a composite material, comprising the following steps:

[0036] Step 1, using the hydrothermal synthesis method to prepare MIL-125-NH 2 / TiO 2 composite material, and the MIL-125-NH 2 / TiO 2 After the composite material is vacuum-dried, it is sealed and stored for future use;

[0037] Step 2, put the indium tin oxide electrode in the cleaning solution, gently scrub the surface with a cotton ball, rinse with distilled water, and place it in absolute ethanol for ultrasonic treatment for 5 minutes, take out the indium tin oxide electrode, rinse with distilled water, and blow dry with nitrogen ,spare;

[0038] Step 3, the MIL-125-NH prepared in step 1 2 / TiO 2 The composite material is dispersed in ultrapure water to obtain a uniform dispersion, and 30 μL of the uniform dispersion is drip-coated on the surface of the indium tin oxide electrode (ITO) treated in st...

Embodiment 3

[0045] A MIL-125-NH based 2 / TiO 2 A method for preparing a molecularly imprinted photoelectrochemical sensor of a composite material, comprising the following steps:

[0046] Step 1, using the hydrothermal synthesis method to prepare MIL-125-NH 2 / TiO 2 composite material, and the MIL-125-NH 2 / TiO 2 After the composite material is vacuum-dried, it is sealed and stored for future use;

[0047] Step 2, put the indium tin oxide electrode in the cleaning solution, gently scrub the surface with a cotton ball, rinse with distilled water, and place it in absolute ethanol for ultrasonic treatment for 5 minutes, take out the indium tin oxide electrode, rinse with distilled water, and blow dry with nitrogen ,spare;

[0048] Step 3, the MIL-125-NH prepared in step 1 2 / TiO 2 The composite material was dispersed in ultrapure water to obtain a uniform dispersion, and 50 μL of the uniform dispersion was drip-coated on the surface of the indium tin oxide electrode (ITO) treated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com