Preparation method of Ag-AgBr/TiO2 nanorod composite array film

A technology of nanorod arrays and composite arrays, which is applied in the field of photocatalytic material preparation, can solve the problems of low photoelectrochemical performance of sunlight photocatalytic activity, low utilization of sunlight, limited practical application, etc., and achieves a simple preparation route and avoids agglomeration. phenomenon, the effect of low interfacial charge transport resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

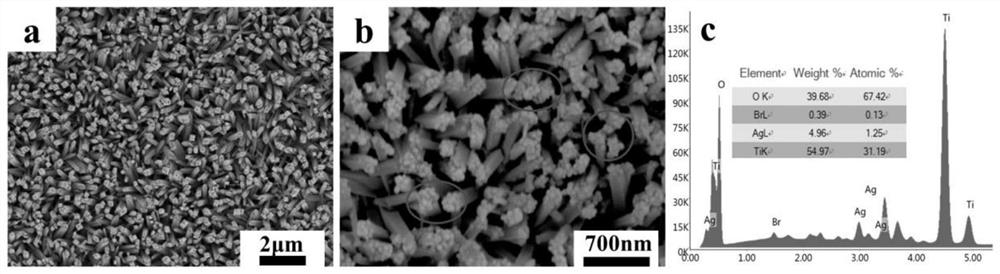

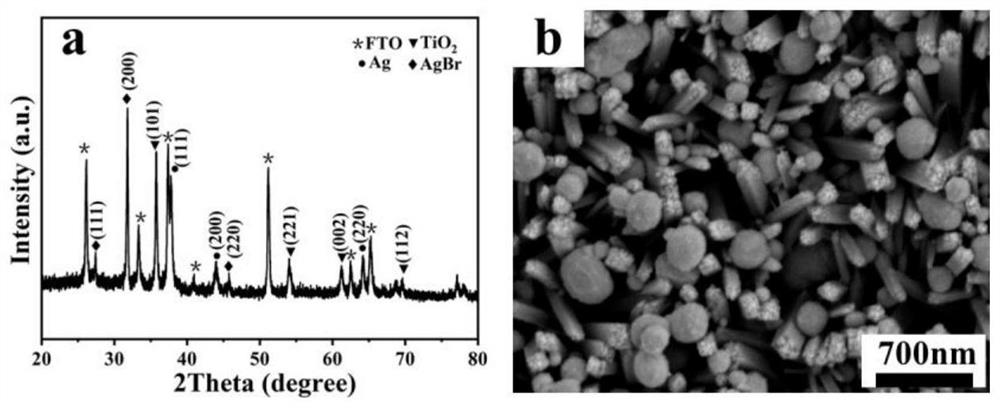

[0034] (1) Cut the FTO conductive glass into a suitable size of 2.5cm×5cm with a glass knife, and then use acetone, deionized water and absolute ethanol to ultrasonically clean it for 20 minutes to remove dust and pollutants on the glass surface, and then measure 15mL of concentrated hydrochloric acid (37%) and 0.5mL tetrabutyl titanate, add 15mL deionized water, stir at room temperature for 30min, stirring speed 200r / min, then pour it into 50mL of cleaned FTO glass (conductive side down) at the bottom In the liner of the high-pressure reactor, react under hydrothermal conditions at 150°C for 12h, take out the sample and wash it three times with absolute ethanol and deionized water, and dry it at 60°C for 10h to obtain the product TiO 2 Nanorod array films;

[0035] (2) Dissolve 0.1mmol sodium hydroxide in 35mL deionized water, add 0.1g hexadecyltrimethylammonium bromide and 1mmol silver nitrate successively to the above solution under magnetic stirring conditions, and continu...

Embodiment 2

[0039] (1) Cut the FTO conductive glass into a suitable size of 1.5cm×4cm with a glass knife, and use acetone, deionized water and absolute ethanol to clean it ultrasonically for 40 minutes to remove dust and pollutants on the glass surface, and then measure 15mL of concentrated hydrochloric acid (37%) and 0.5mL tetrabutyl titanate, add 15mL deionized water, stir at room temperature for 40min, stirring speed 180r / min, then pour it into 75mL of cleaned FTO glass (conductive side down) at the bottom In the liner of the high-pressure reactor, react under hydrothermal conditions at 160°C for 12h, take out the sample and wash it with absolute ethanol and deionized water for 5 times, and dry it at 80°C for 15h to obtain the product TiO 2 Nanorod array films;

[0040] (2) Dissolve 0.1mmol of hexamethylenetetramine in 35mL of deionized water, and add 0.1g of hexadecyltrimethylammonium bromide and 1mmol of silver nitrate to the above solution successively under magnetic stirring condit...

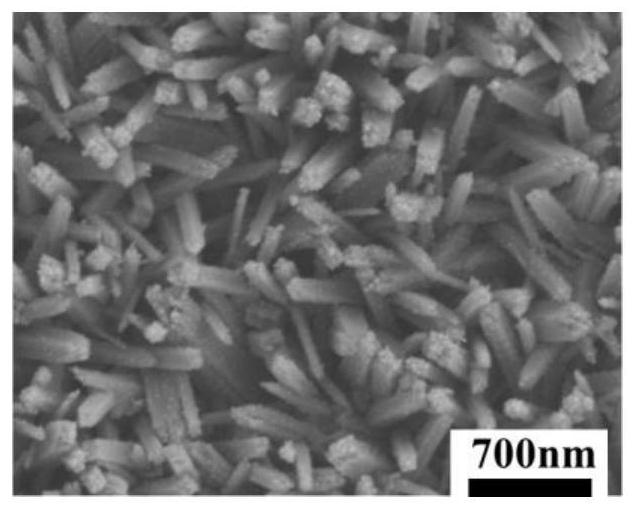

Embodiment 3

[0044] (1) Cut the FTO conductive glass into a suitable size of 2.5cm×5cm with a glass knife, and then use acetone, deionized water and absolute ethanol to ultrasonically clean it for 30 minutes to remove dust and pollutants on the glass surface, and then measure 15mL of concentrated hydrochloric acid (37%) and 0.5mL tetrabutyl titanate, add 15mL deionized water, stir at room temperature for 30min, stirring speed 200r / min, then pour it into 50mL of cleaned FTO glass (conductive side down) at the bottom In the liner of the high-pressure reactor, react under hydrothermal conditions at 150°C for 12h, take out the sample and wash it three times with absolute ethanol and deionized water, and dry it at 60°C for 12h to obtain the product TiO 2 Nanorod array films;

[0045] (2) Dissolve 0.08mmol sodium hydroxide in 35mL deionized water, add 0.1g hexadecyltrimethylammonium bromide and 1mmol silver nitrate successively to the above solution under magnetic stirring conditions, and contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com