Bismuth vanadate-metal organic complex composite photoelectrode and preparation method and application thereof

A technology of metal-organic complexes, applied in the field of photoelectrodes, can solve the problems of poor photoelectrochemical performance, limited stability, slow kinetics, etc., and achieve excellent photoelectrochemical performance, reduce surface recombination rate, and increase photocurrent density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

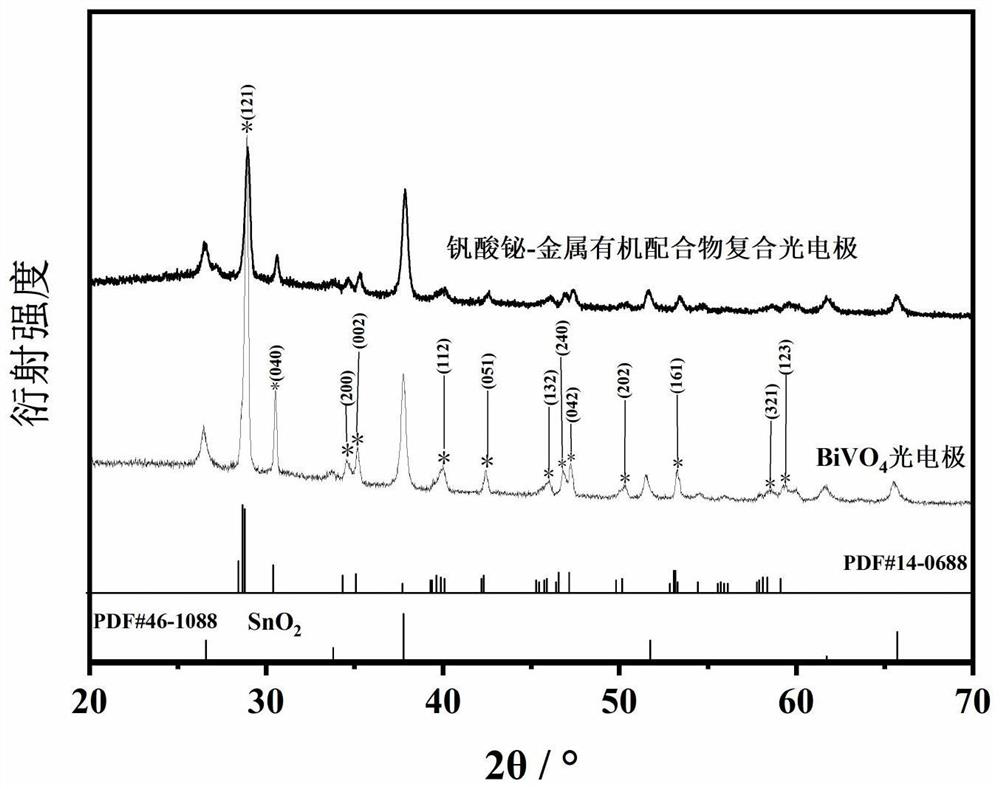

[0041] The present invention also provides a method for preparing a bismuth vanadate-metal organic complex composite photoelectrode described in the above technical solution, comprising the following steps:

[0042] Provide BiVO 4 photoelectrode, the BiVO 4 The photoelectrode includes a substrate and BiVO loaded on the surface of the substrate 4 thin film, the BiVO 4 Thin films made of BiVO 4 particle formation;

[0043] mixing an inorganic metal salt, an organic ligand and a solvent to obtain an inorganic metal salt-ligand mixed liquid; the inorganic metal salt includes an inorganic ferrous salt; the organic ligand is 2,5-dihydroxyterephthalic acid;

[0044] BiVO 4 The photoelectrode is immersed in the inorganic metal salt-ligand mixed solution, and the hydrothermal reaction is carried out to obtain the bismuth vanadate-metal organic complex composite photoelectrode.

[0045] In the present invention, unless otherwise specified, each reagent in the preparation method is...

Embodiment 1

[0083] Potassium iodide and ultrapure water were mixed, and the concentrated nitric acid with a concentration of 68wt% was used to adjust the pH value to 1.7 to obtain a potassium iodide aqueous solution with a concentration of 0.5mol / L; bismuth nitrate was mixed with the potassium iodide aqueous solution, and ultrasonically dissolved to obtain bismuth nitrate Concentration is the potassium iodide-bismuth nitrate mixed solution of 0.06mol / L;

[0084] P-benzoquinone is mixed with ethanol, and ultrasonically dissolved to obtain an ethanol solution of p-benzoquinone with a p-benzoquinone concentration of 0.3mol / L;

[0085] Mix the potassium iodide-bismuth nitrate mixed solution and the ethanol solution of p-benzoquinone at a volume ratio of 5:2, and stir evenly to obtain an electrolyte solution; in the presence of the electrolyte solution, use FTO conductive glass as the working electrode, Ag The / AgCl electrode is used as the reference electrode, and the platinum mesh is used as...

Embodiment 2

[0095] Prepare BiVO according to the method of Example 1 4 Photoelectrode;

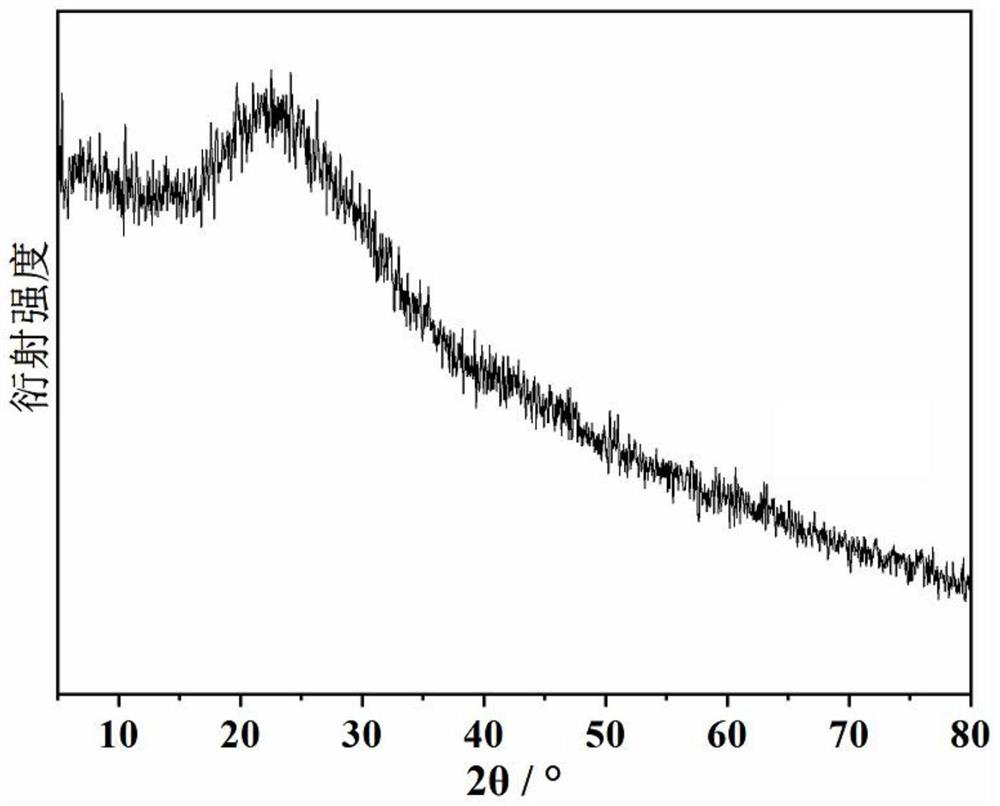

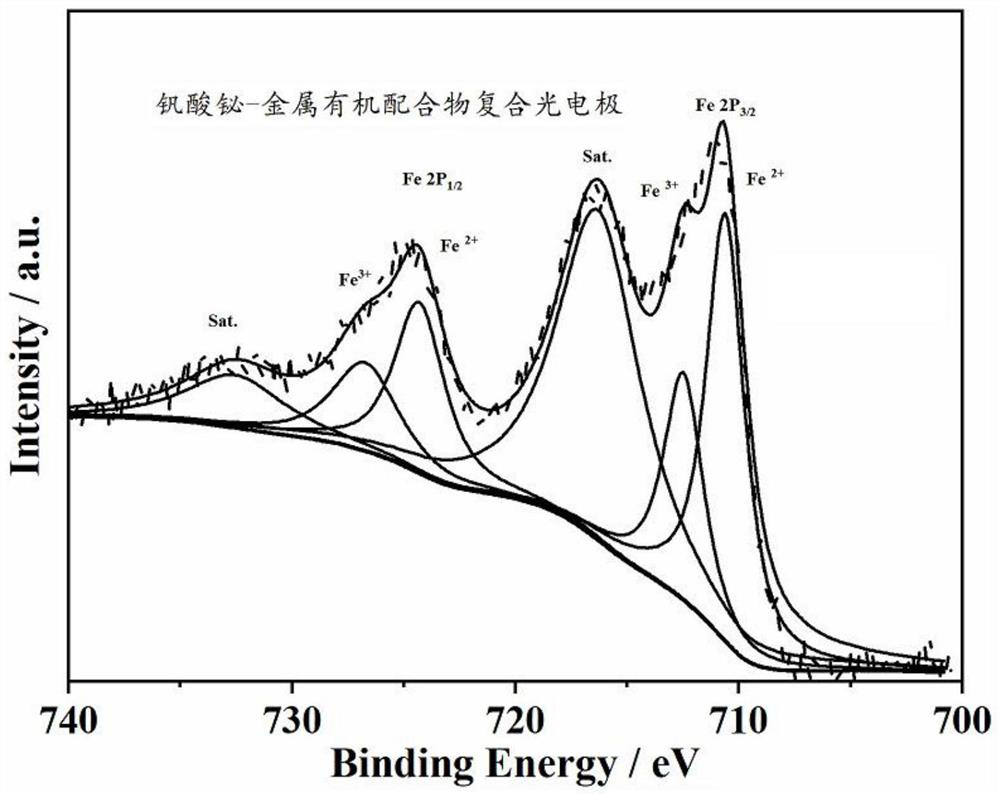

[0096] Mix ferrous chloride, ligand 2,5-dihydroxyterephthalic acid and a solvent, wherein the solvent is a mixed solution of ethanol, water and N,N-dimethylformamide, ethanol, water and N,N -The volume ratio of dimethylformamide is 1:1:20 to obtain the inorganic ferrous salt-ligand mixed solution, the concentration of ferrous chloride in the inorganic ferrous salt-ligand mixed solution is 10.42mmol / L , the concentration of ligand is 22.22mmol / L;

[0097] The resulting BiVO 4 The photoelectrode is placed in a stainless steel autoclave, and the conductive surface leans against the lining of the stainless steel autoclave, and the inorganic ferrous salt-ligand solution is added to the lining of the stainless steel autoclave until the BiVO is submerged. 4 The photoelectrode was subjected to a hydrothermal reaction at 120°C for 8 hours. After the reaction, the resulting hydrothermal reaction product was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com