High-performance heterojunction material Fe2O3/CuO photoelectrode film as well as preparation method and application thereof

A heterojunction, high-performance technology, applied in the field of photoelectrochemistry, can solve problems such as no related reports, achieve good development prospects, cheap and easily available raw materials, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of high-performance p-type material CuO photoelectrode powder

[0031] (1) Preparation method

[0032] Dissolve 3.99g of copper sulfate and 5.7mL of 1.3M lactic acid in 50mL of deionized water, stir well, and titrate with 0.5M NaOH to make the pH=11. After the precipitate was completely precipitated, the precipitate was centrifuged, washed, and dried in an oven at 60° C. for 12 hours to obtain a CuO precursor.

[0033] The CuO precursor was calcined in a muffle furnace at 550° C. for 2 h, cooled to room temperature, and then ground to obtain CuO powder, a p-type photoelectrode material.

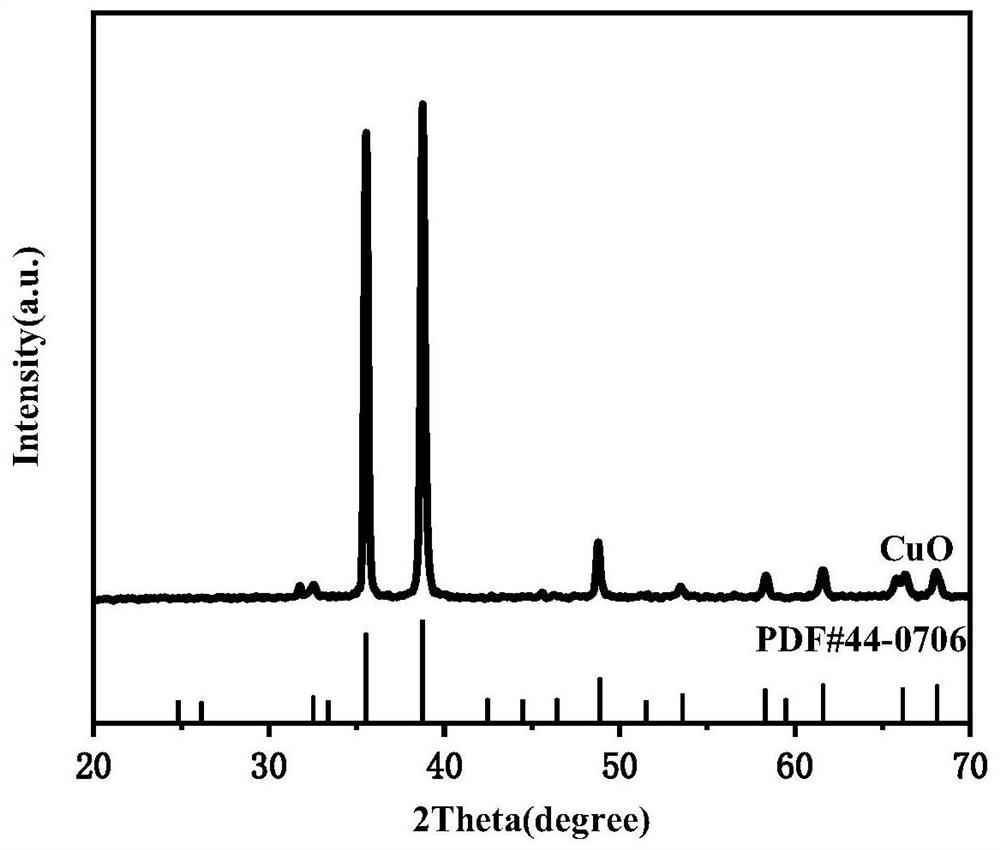

[0034] (2) Detection

[0035] figure 1 Be the XRD pattern of the photoelectrode material CuO prepared in embodiment 1, by figure 1 It can be seen that the sample has nine obvious diffraction peaks at 32.2°, 33.1°, 35.2°, 38.5°, 48.6°, 53.3°, 58.0°, 61.3°, 65.9°, and 67.9°, which are characteristic peaks of CuO. Pure CuO photoelectrodes The diffraction peaks of th...

Embodiment 2

[0036] Embodiment 2 A kind of high-performance n-type material Fe 2 o 3 Photoelectrode film

[0037] (1) Preparation method

[0038] Dissolve 0.6g of ferric chloride hexahydrate and 1.27g of sodium nitrate in 15mL of deionized water, and stir well to prepare the precursor solution. FTO was cleaned with deionized water and ethanol.

[0039] The precursor solution and FTO were placed in a 50mL hydrothermal kettle, and heated at 100°C for 10h to obtain a FeOOH film.

[0040] The FeOOH film was calcined in a tube furnace at 650 °C for 2 h to obtain a high-performance n-type photoelectrode material Fe 2 o 3 .

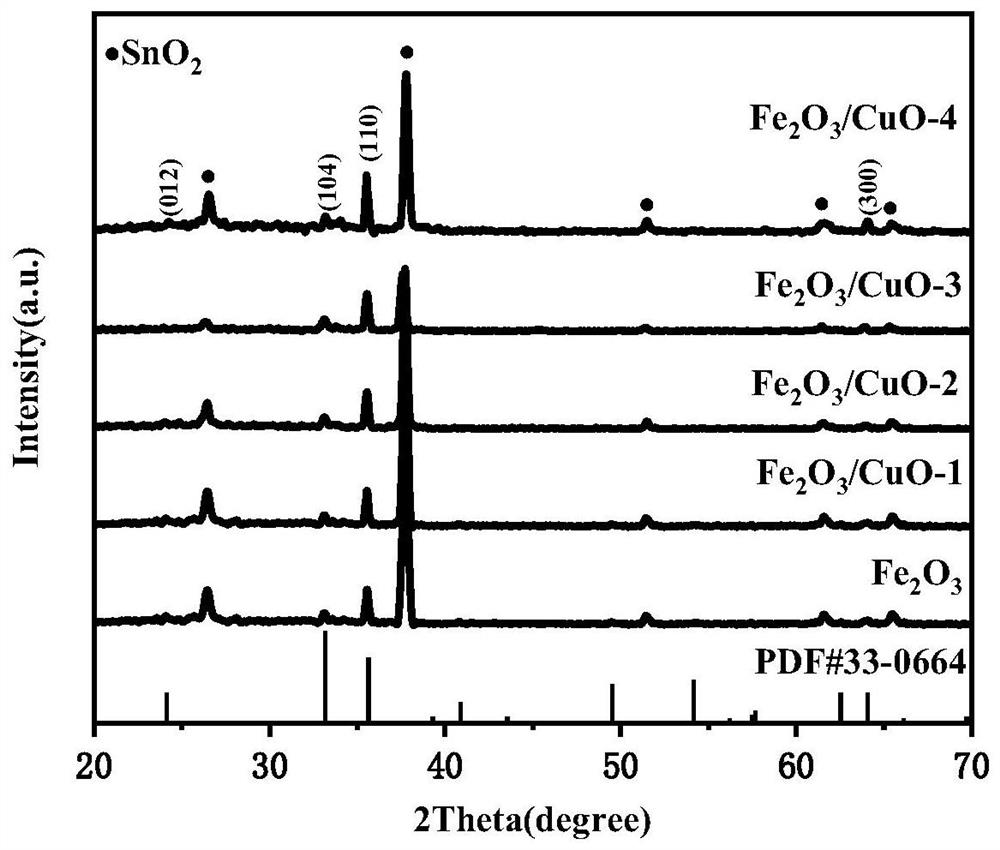

Embodiment 3

[0041] Example 3 A high-performance heterojunction material Fe 2 o 3 / CuO photoelectrode film

[0042] (1) Preparation method

[0043] 60 mg of the CuO powder prepared in Example 1 and 0.5 mL of polyethylene glycol were dissolved in 50 mL of ethanol solution, and ultrasonicated for 60 min to obtain a precursor solution.

[0044] Fe prepared by embodiment 2 2 o 3 The film was immersed in the precursor solution, the immersion time was 1 min, and the immersion rate was 1 cm / min.

[0045] The thin film impregnated once was calcined in a muffle furnace at 450 °C for 1 h to obtain a high-performance heterojunction material Fe 2 o 3 / CuO-1 photoelectrode film.

[0046] The film impregnated twice was calcined in a muffle furnace at 450 °C for 1 h to obtain a high-performance heterojunction material Fe 2 o 3 / CuO-2 photoelectrode film.

[0047] The thin film impregnated three times was calcined in a muffle furnace at 450 °C for 1 h to obtain a high-performance heterojunction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com