Ce-doped W18O49 nanowire photocatalyst and preparation method thereof

A technology of W18O49 and photocatalyst, which is applied in the field of photocatalytic nitrogen fixation materials, can solve the problems of insufficient photocatalytic nitrogen fixation performance of nanowires, achieve high photocatalytic nitrogen fixation activity and stability, simple preparation method, and improve the efficiency of photocatalytic nitrogen fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

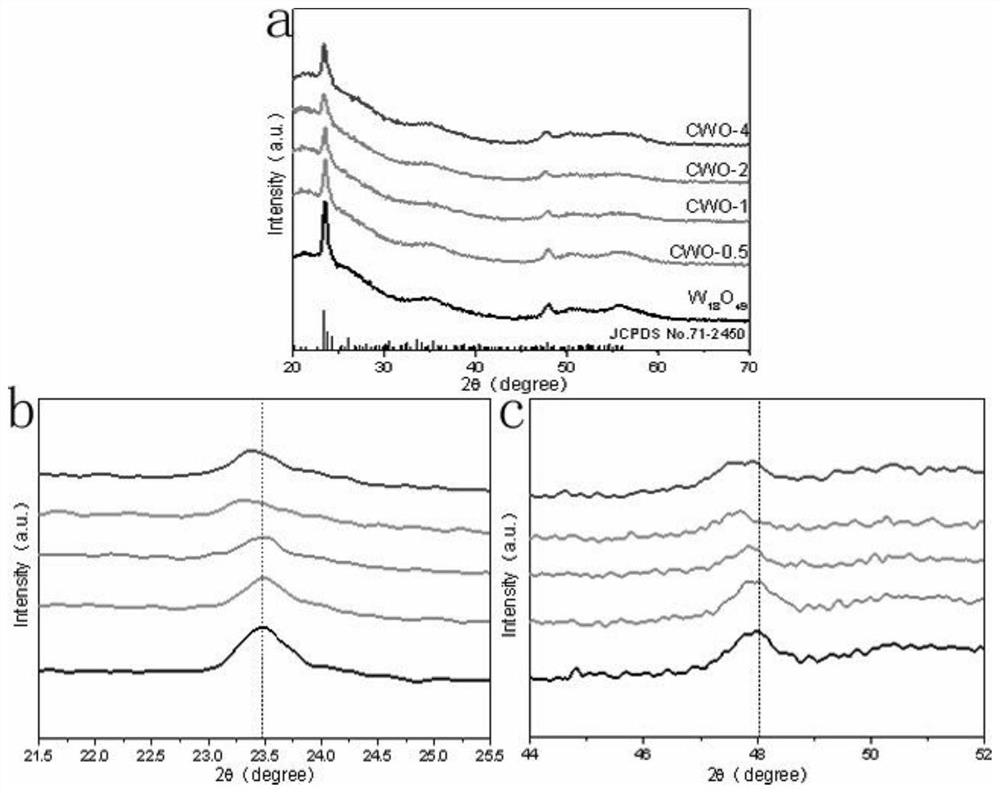

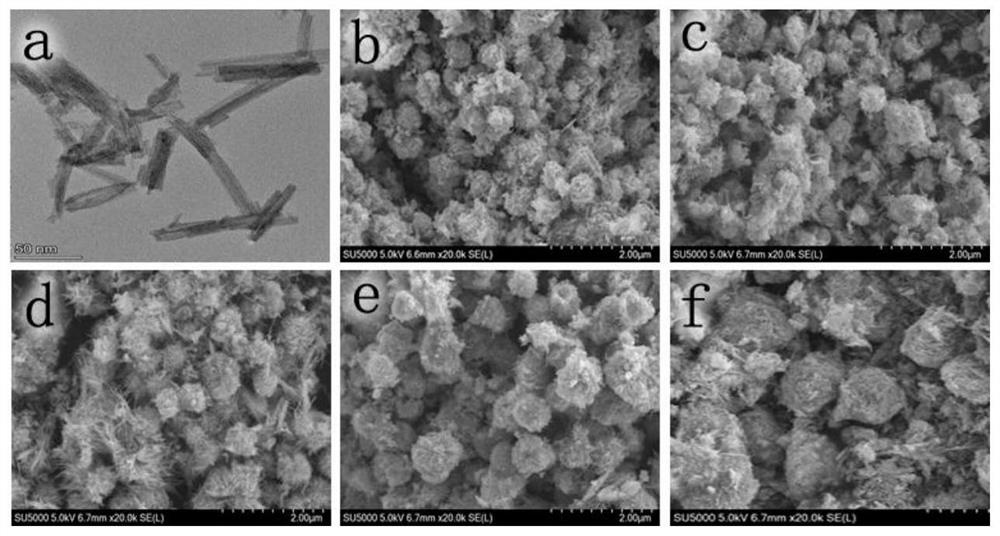

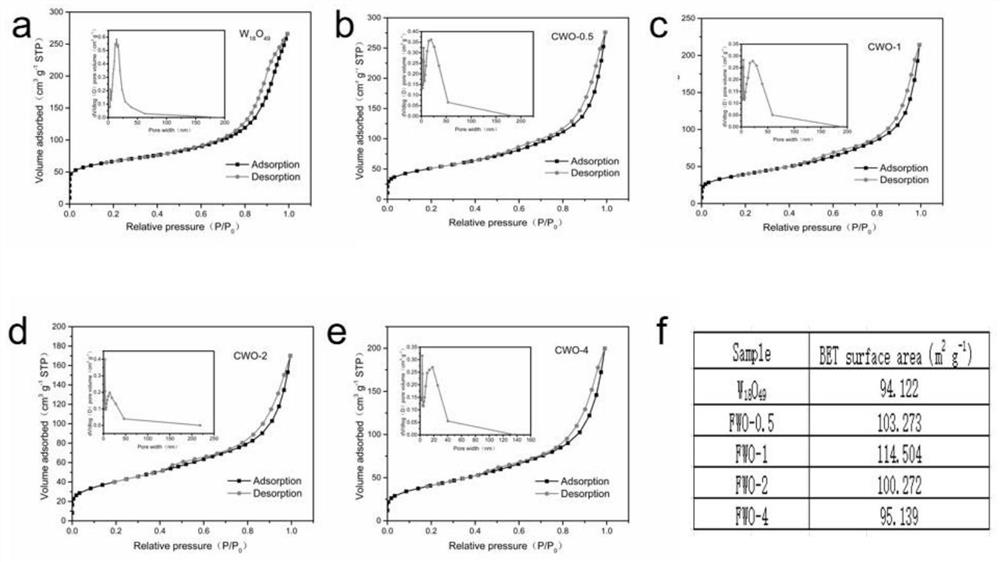

[0029] A Ce-doped W 18 o 49 Nanowire photocatalyst preparation method, comprising the following steps:

[0030] First weigh 0.3g WCl 6 Pour the sample into a beaker, then weigh 70mL of ethanol into the beaker with a measuring cylinder, add a magnet and stir for 30 minutes. Then add 0.1553mg CeCl 3 , CeCl 3 The molar ratio to tungsten hexachloride is 0.5%, and then stirred for 10 minutes. After the stirring is completed, the mixed solution is transferred to a 100mL reaction kettle, and the solvent is carried out at a temperature of 200°C and a holding time of 12h. Thermal reaction, centrifuge the sample after the reaction kettle is naturally cooled, wash with ethanol 2-3 times, and then put it in a 60°C oven to dry for later use.

Embodiment 2

[0032] A Ce-doped W 18 o 49 Nanowire photocatalyst preparation method, comprising the following steps:

[0033] First weigh 0.3g WCl 6 Pour the sample into a small beaker, then weigh 70mL of ethanol into the beaker with a measuring cylinder, add a magnet and stir for 30 minutes. Then add 0.3107mg CeCl 3 , CeCl 3 The molar ratio to tungsten hexachloride is 1%, and then stirred for 10 minutes. After the stirring is completed, the mixed solution is transferred to a 100mL reaction kettle, and the solvent is carried out at a temperature of 200°C and a holding time of 12h. Thermal reaction, centrifuge the sample after the reaction kettle is naturally cooled, wash with ethanol 2-3 times, and then put it in a 60°C oven to dry for later use.

Embodiment 3

[0035] A Ce-doped W 18 o 49 Nanowire photocatalyst preparation method, comprising the following steps:

[0036] Put the 100mL small beaker on the table, first weigh 0.3g WCl 6 Pour the sample into a small beaker, then weigh 70mL of ethanol into the beaker with a measuring cylinder, add a magnet and stir for 30 minutes. Then add 0.6215mg CeCl 3 , CeCl 3 The molar ratio to tungsten hexachloride is 2%, and then stirred for 10 minutes. After the stirring is completed, the mixed solution is transferred to a 100mL reaction kettle, and the solvent is carried out at a temperature of 200°C and a holding time of 12h. Thermal reaction, centrifuge the sample after the reaction kettle is naturally cooled, wash with ethanol 2-3 times, and then put it in a 60°C oven to dry for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com