Preparation method of tungsten trioxide nano film

A nano-film, tungsten trioxide technology, applied in electrodes, electrolysis process, electrolysis components, etc., to achieve excellent photoelectric performance and high stability, alleviate the shortage of fossil fuels, and the process is flexible and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

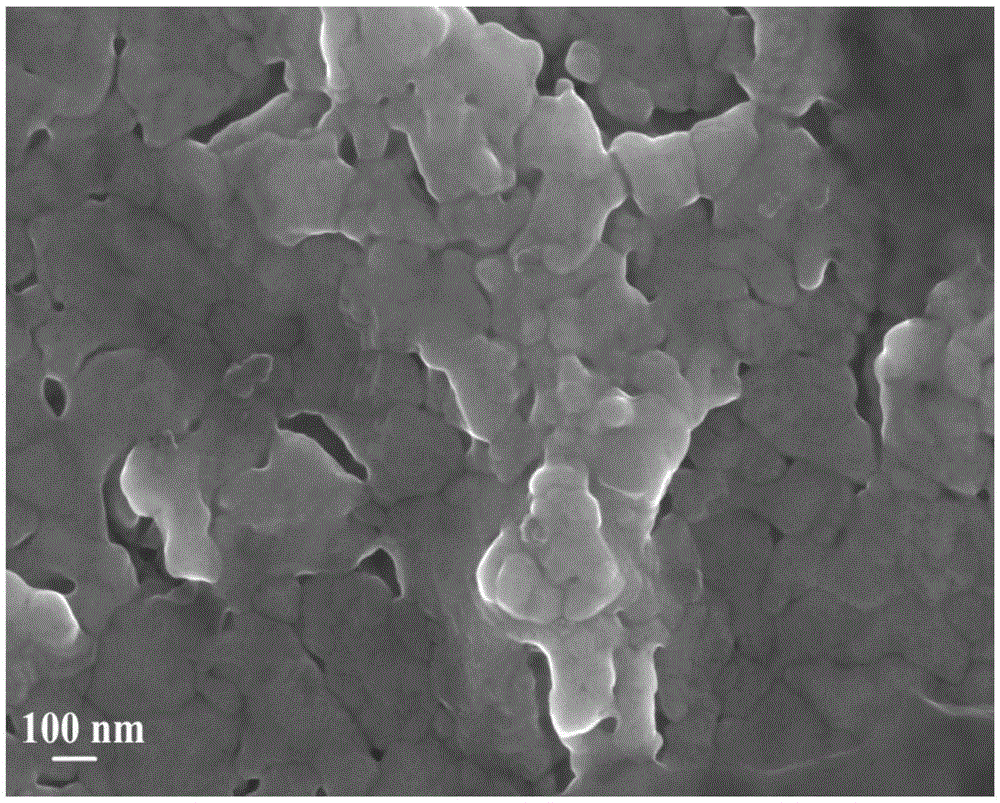

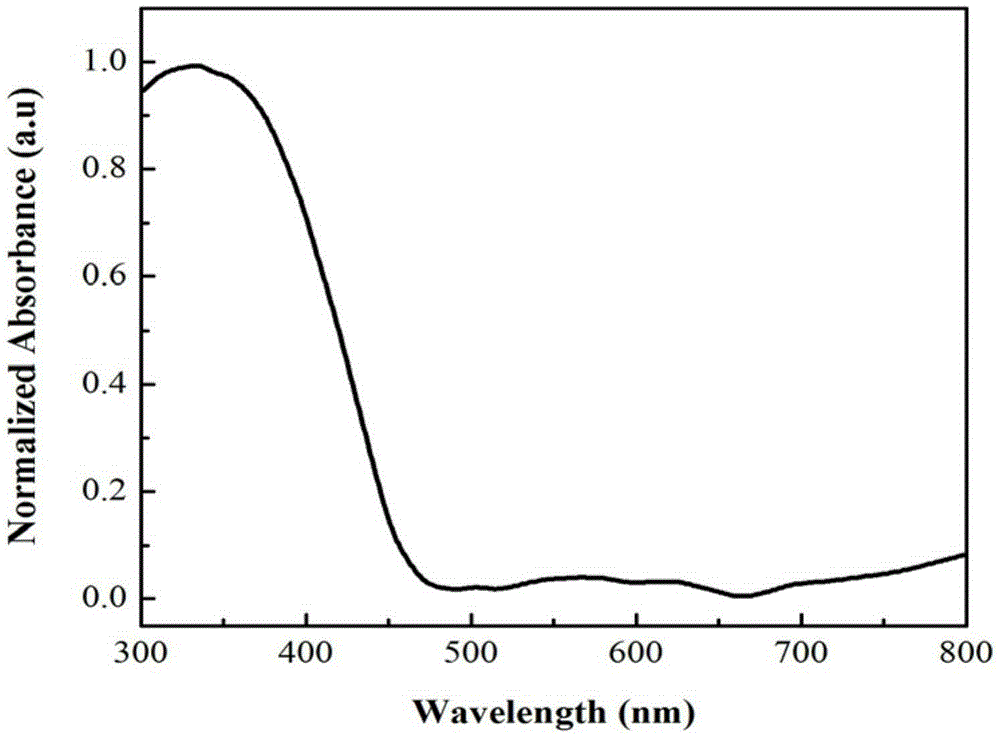

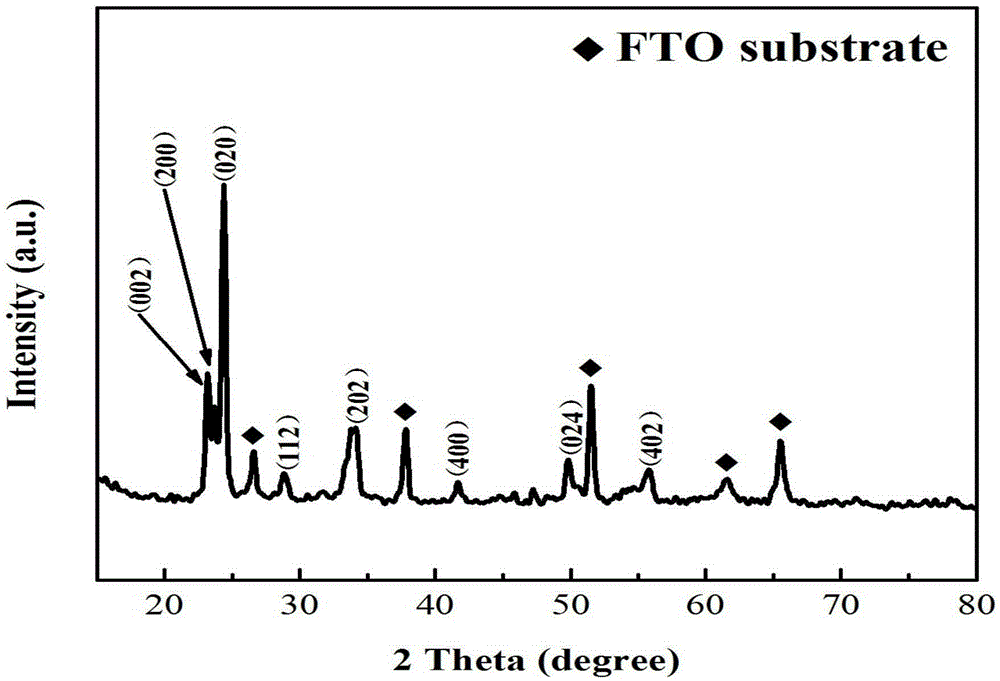

Image

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

[0028] Step 1, dissolving tungsten hexachloride in absolute ethanol, and magnetic stirring for 15 minutes to obtain a precursor solution; the molar concentration of tungsten hexachloride in the precursor solution is 40mmol / L;

[0029] Step 2. Apply 10 μL of the precursor solution described in step 1 onto a surface area of 1 cm by the drop coating method. 2 The surface of the substrate, after the precursor solution is spread on the surface of the substrate, it is blown dry with nitrogen, and then the substrate is heat-treated at 100°C for 5 minutes and then cooled to room temperature; Preferably, a micropipette is used to absorb the precursor solution, and the substrate is preferably FTO conductive glass;

[0030] Step 3, repeat step 2 20 times to obtain a film layer on the surface of the substrate;

[0031] Step 4. Place the substrate on a heating plate, and then heat the film layer in step 3 to 450°C for 4 hours at a ...

Embodiment 2

[0034] This embodiment is the same as Embodiment 1, the difference being that in step three, step two is repeated five times to obtain a film layer on the surface of the substrate; film.

Embodiment 3

[0036] This embodiment is the same as Embodiment 1, the difference being that in step three, step two is repeated 10 times to obtain a film layer on the surface of the substrate; film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com