Method for preparing tungsten trioxide film based room temperature gas sensor element

A gas sensor, tungsten trioxide technology, applied in the direction of material resistance, etc., can solve the problems of unfavorable gas sensor integration and intelligence, resistance increase, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

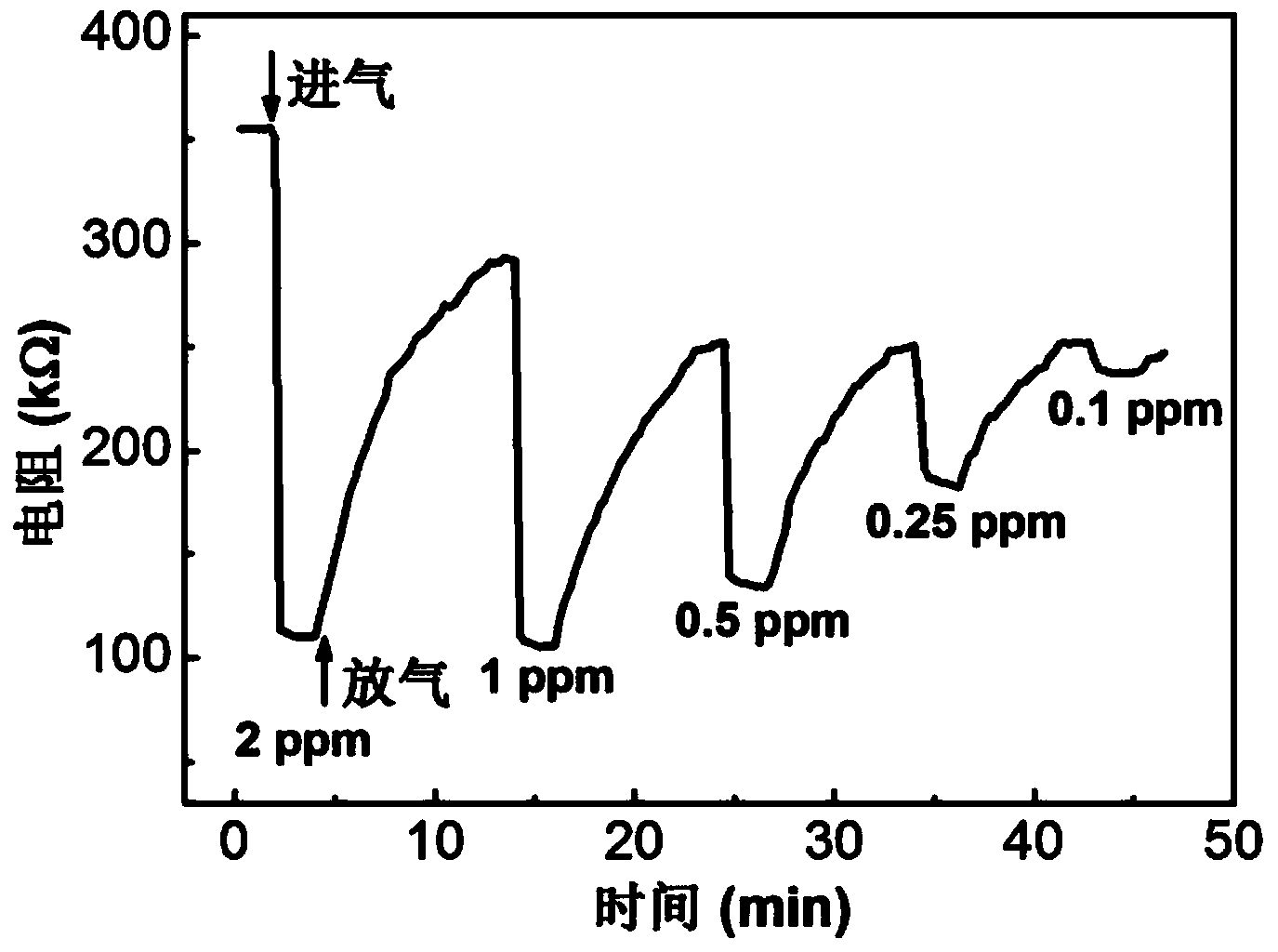

Embodiment 1

[0028] 1) Silicon wafer cleaning

[0029] Cut a p-type single-sided polished single-crystal silicon wafer with a resistivity of 10-15Ω·cm, a thickness of 400μm, and a crystal orientation into a rectangular silicon substrate with a size of 2.5cm×1cm, and put it into the prepared hydrogen peroxide : Soak in concentrated sulfuric acid = 1:3 cleaning solution for 40 minutes to remove surface organic pollutants; rinse with deionized water and soak in 5% hydrofluoric acid aqueous solution for 30 minutes to remove surface oxide layer; rinse with deionized water Then put it into acetone solvent, absolute ethanol, and deionized water for ultrasonic cleaning for 15 minutes, respectively, to clean off the ions and organic impurities on the surface, and dry it for later use.

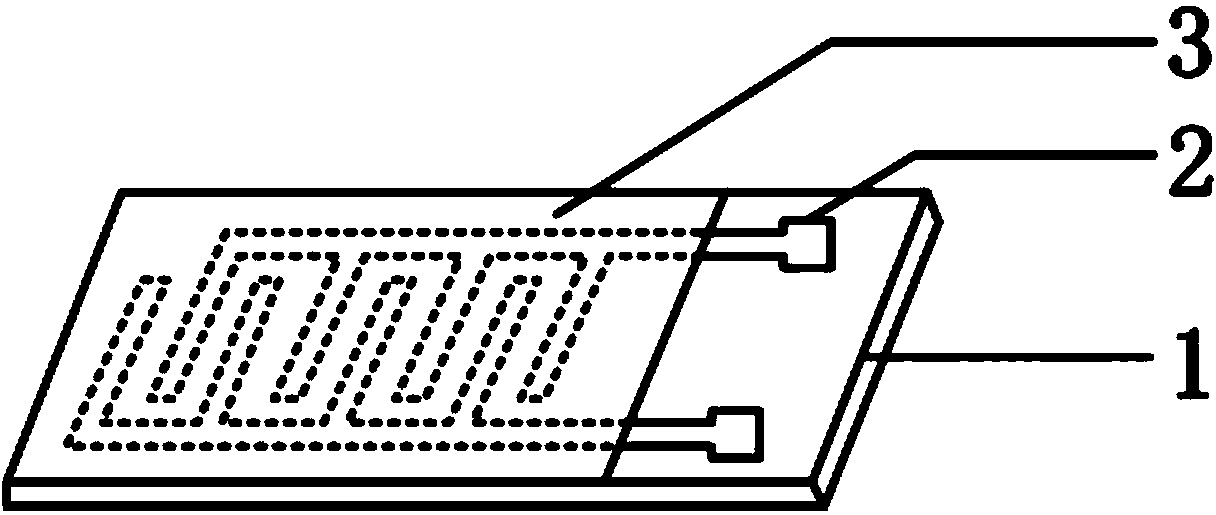

[0030] 2) Sputtering platinum interdigitated electrodes

[0031] The cleaned and dried p-type single crystal silicon substrate samples were placed in the vacuum chamber of the DPS-Ⅲ ultra-high vacuum counter-targe...

Embodiment 2

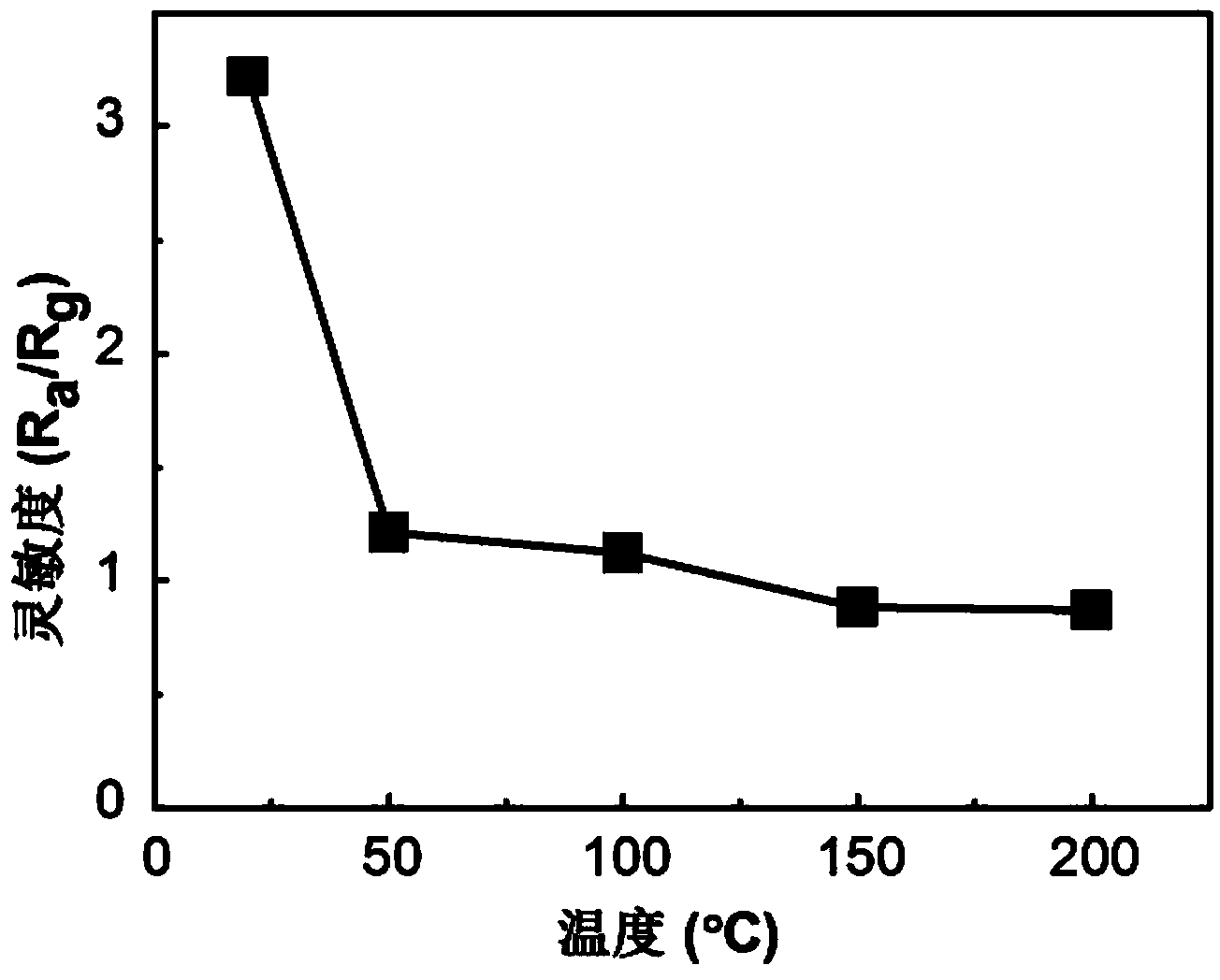

[0038] The difference between this example and Example 1 is that the heat treatment temperature of the sample substrate after spin coating in step 3) is 350°C, and the prepared silicon-based tungsten trioxide thin film gas sensor element is resistant to 2ppm NO at room temperature. 2 The sensitivity is 1.03, showing the gas-sensing characteristics of p-type semiconductors.

Embodiment 3

[0040]The difference between this example and Example 1 is that the heat treatment temperature of the sample substrate after spin coating in step 3) is 500°C, and the prepared silicon-based tungsten trioxide thin film gas sensor element is resistant to 2ppm NO at room temperature. 2 Shown as the gas-sensing characteristic of p-type semiconductor, the sensitivity is 1.84.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com