Oxygen-vacancy tungsten oxide/carbon nitride composite photocatalyst and preparation method and application thereof

A carbon nitride and catalyst technology, applied in the field of photocatalysis, can solve the problems of high recombination rate of photogenerated electron-hole pairs, small specific surface area of simple carbon nitride, and limitation of photocatalytic efficiency development, etc., and achieve large band gap, Excellent photocatalytic activity, high repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

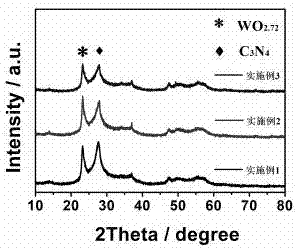

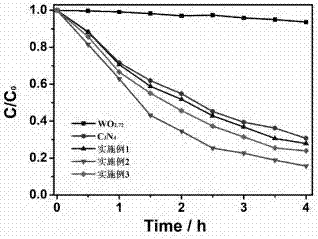

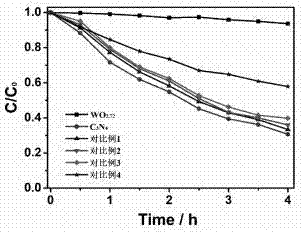

[0031] A kind of oxygen vacancy tungsten oxide / carbon nitride composite photocatalyst, described (WO 2.72 / C 3 N 4 ) The preparation method of the composite photocatalyst is as follows:

[0032] (1) Weigh 20g of urea and place it in a ceramic crucible with a lid, raise the temperature to 550°C in a muffle furnace at a rate of 2°C / min, keep it for 4 hours, and cool naturally to room temperature to obtain carbon nitride powder; take and prepare 0.5 g of the carbon nitride powder was dispersed in 500 ml of hydrochloric acid with a concentration of 6 M, and after continuous stirring for 24 hours, the carbon nitride powder was collected by centrifugation, washed three times with deionized water and dried;

[0033] (2) Weigh 0.1g of protonated carbon nitride and disperse it in 75ml of absolute ethanol and sonicate for 10min, add 0.0398g of WCl 6 (The mass ratio of carbon nitride and WCl6 is 1:0.398); placed in a high-pressure reactor, 200 ° C hydrothermal treatment for 12 hours; ...

Embodiment 2

[0036] A kind of oxygen vacancy tungsten oxide / carbon nitride composite photocatalyst, described (WO 2.72 / C 3 N 4 ) The preparation method of the composite photocatalyst is as follows:

[0037] (1) Weigh 20g of urea and place it in a ceramic crucible with a lid, raise the temperature to 550°C in a muffle furnace at a rate of 2°C / min, keep it for 3 hours, and cool naturally to room temperature to obtain carbon nitride powder; take and prepare 0.5 g of the carbon nitride powder was dispersed in 500 ml of hydrochloric acid with a concentration of 5 M, and after continuous stirring for 24 hours, the carbon nitride powder was collected by centrifugation, washed three times with deionized water and dried;

[0038] (2) Weigh 0.1g of protonated carbon nitride and disperse it in 75ml of absolute ethanol and sonicate for 10min, add 0.099g of WCl 6 (The mass ratio of carbon nitride and WCl6 is 1:0.99); placed in a high-pressure reactor, 180 ° C hydrothermal treatment for 15 hours;

...

Embodiment 3

[0041] A kind of oxygen vacancy tungsten oxide / carbon nitride composite photocatalyst, described (WO 2.72 / C 3 N 4 ) The preparation method of the composite photocatalyst is as follows:

[0042](1) Weigh 20g of urea and place it in a ceramic crucible with a lid, raise the temperature to 550°C in a muffle furnace at a rate of 2°C / min, keep it for 3 hours, and cool naturally to room temperature to obtain carbon nitride powder; take and prepare 0.5 g of the carbon nitride powder was dispersed in 500 ml of hydrochloric acid with a concentration of 7 M, and after continuous stirring for 24 hours, the carbon nitride powder was collected by centrifugation, washed three times with deionized water and dried;

[0043] (2) Weigh 0.1g of protonated carbon nitride and disperse it in 75ml of absolute ethanol and sonicate for 10min, add 0.1985g of WCl 6 (Carbon Nitride and WCl 6 The mass ratio is 1:1.985); placed in a high-pressure reactor, 220 ° C hydrothermal treatment for 10 hours;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com