Preparation method of antimony-doped tin dioxide nano-slurry

A tin dioxide and nano-slurry technology, applied in the directions of tin oxide, nanotechnology, nanotechnology, etc., can solve the problems of uneven dispersion, difficult dispersion, and difficult cleaning and removal of chloride ions, avoiding hard agglomeration and ensuring optical performance. , to avoid the effect of larger particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

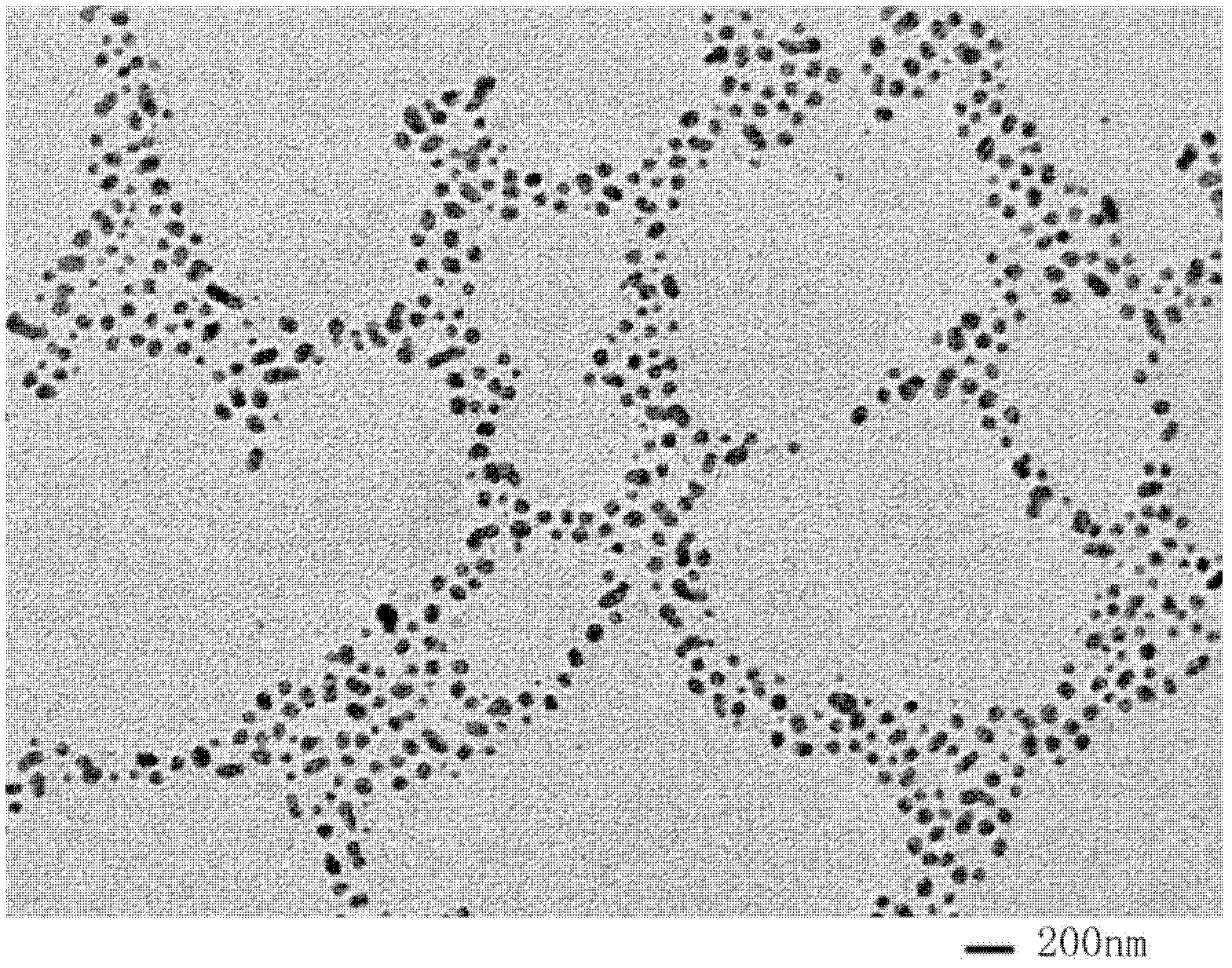

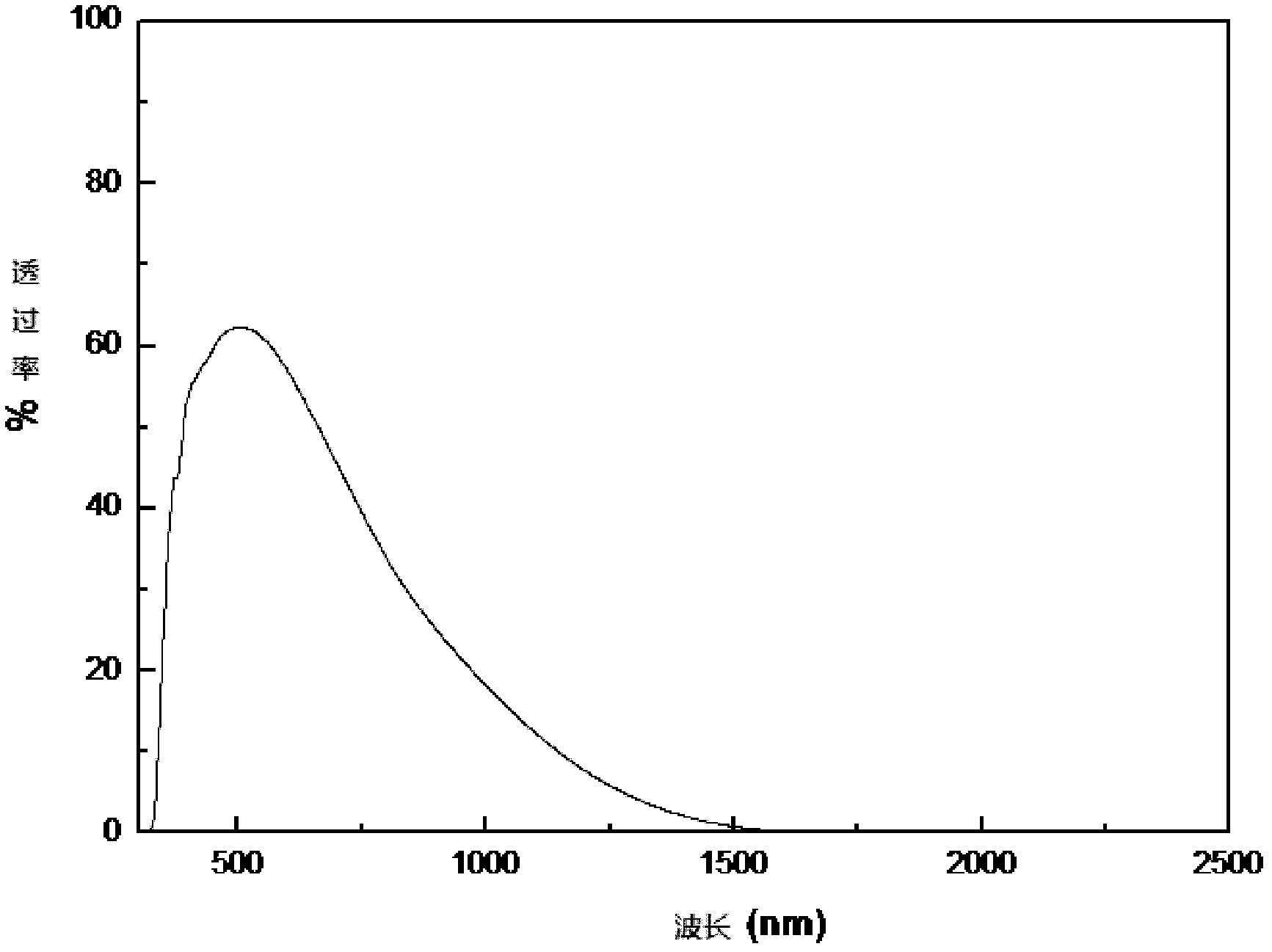

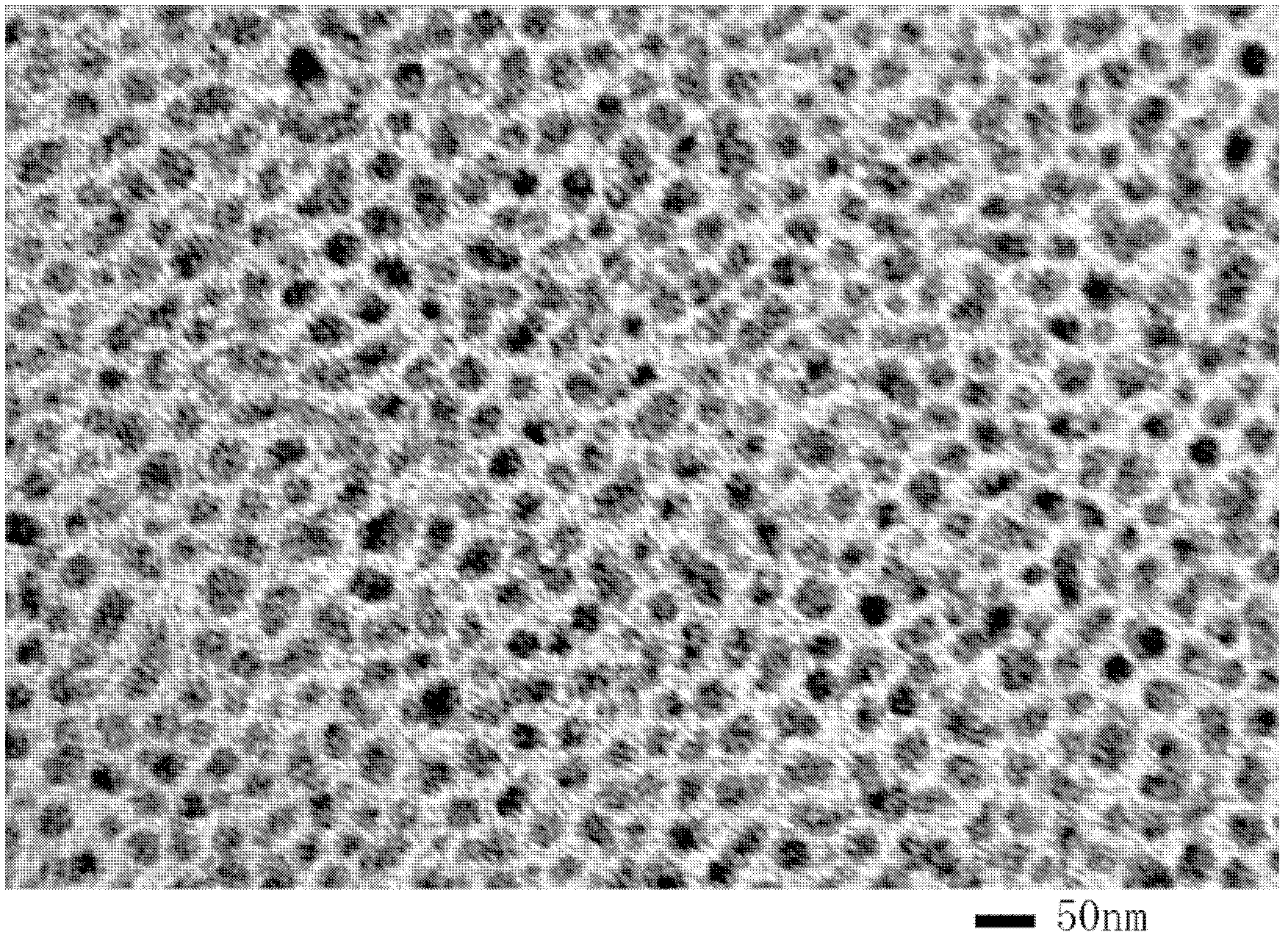

[0035] The embodiment of the present invention provides a preparation method of nano-antimony-doped tin dioxide (ATO) slurry, the method directly obtains ATO slurry by chemical reaction, without ATO powder dispersion, and the infrared absorption effect of nano-ATO slurry is good , the process is simple, the energy consumption is low, and the ATO slurry with a particle size of 20-150nm and good stability and dispersion can be prepared. The method includes:

[0036] A tin and antimony salt solution composed of tin nitrate, ethanol, and antimony nitrate, and a lye composed of sodium hydroxide or ammonia;

[0037] Add the alkali solution dropwise to the salt solution until the pH value of the system is adjusted to 0.8-2, add hydrogen peroxide, and part of the Sb in the system 3+ Oxidized to Sb 5+ , to obtain precipitated tin antimony hydroxide, washing and filtering the tin antimony hydroxide, adding a dispersant, stirring and dispersing in water to obtain a tin antimony hydroxi...

Embodiment 1

[0056] The present embodiment provides a kind of preparation method of nano antimony-doped tin dioxide (ATO) slurry, comprising:

[0057] Weigh 26g of tin tetrachloride, add it to 70ml of ethanol to form a tin tetrachloride ethanol solution, then weigh 7.6g of antimony trichloride and add it to the tin tetrachloride ethanol solution, stir at 70°C for 30 minutes to obtain a metal salt mixture (i.e. salt solution), then weigh a certain amount of 1mol / L sodium hydroxide solution (i.e. lye), dropwise added to the metal salt mixed solution, until the pH=2 of the metal salt mixed solution, add 7.5g The hydrogen peroxide with a mass concentration of 30% was continuously stirred at a temperature of 70° C. for 1 hour to obtain a suspension of tin antimony hydroxide;

[0058] The obtained tin-antimony hydroxide suspension was centrifuged at 5000rmp for 10 minutes to obtain the precipitated tin-antimony hydroxide. The obtained tin-antimony hydroxide was washed three times, and the tin-an...

Embodiment 2

[0062] The present embodiment provides a kind of preparation method of nano antimony-doped tin dioxide (ATO) slurry, comprising:

[0063] Weigh 260g of tin tetrachloride and add it to 250ml of ethanol to form a tin tetrachloride ethanol solution, then weigh 11.4g of antimony trichloride and add it to the tin tetrachloride ethanol solution, stir at 70°C for 30 minutes to obtain a metal salt mixture solution (i.e. salt solution), then weigh a certain amount of 1mol / L sodium hydroxide solution (i.e. lye), and add it dropwise to the metal salt mixture until the pH of the metal salt mixture = 0.8, then add 11.3g The hydrogen peroxide with a mass concentration of 30% was continuously stirred at a temperature of 70° C. for 1 hour to obtain a suspension of tin antimony hydroxide;

[0064] Centrifuge the obtained tin antimony hydroxide suspension at 5000rmp for 10 minutes to obtain precipitated tin antimony hydroxide, wash the obtained tin antimony hydroxide three times, add tin antimo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com