Method for preparing hematite-type nano iron oxide red

A technology of iron oxide red and iron ore type, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of difficult control of particle size distribution, long working cycle, and environmental pollution, so as to shorten the production cycle and reduce pollutants , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

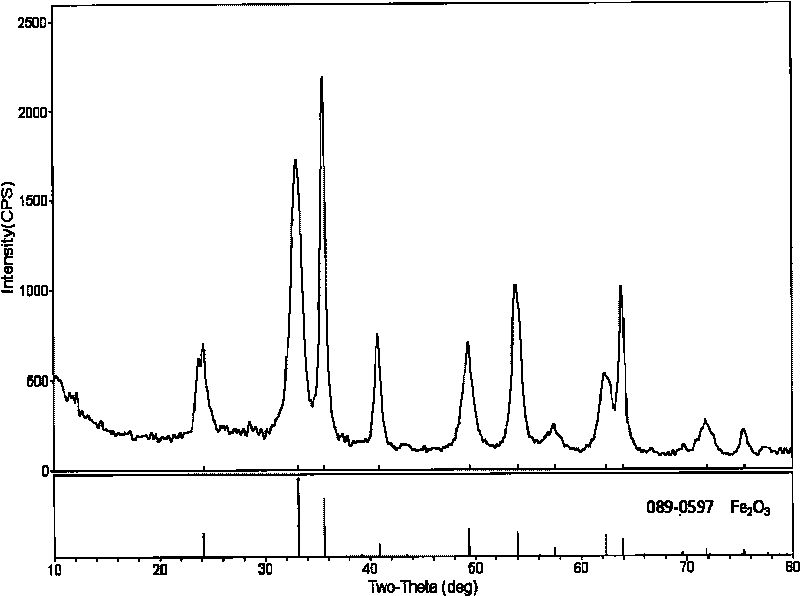

[0022] Dissolve 40g ammonium ferrous sulfate in 100mL deionized water to make Fe 2+ solution, then add a mixture of 1g ammonium polymethacrylate and 0.25g sodium hexametaphosphate, add ammonia water dropwise under stirring to make the pH 4.0-4.5, then add 100mL (10%) sodium hypochlorite, and use ammonia water to control the pH between 4.0-4.5 During this period, the temperature was maintained at 25°C and the reaction was carried out for 60 minutes. After the reaction product settles, it is filtered to obtain a solid, and the solid is dried in a low-temperature vacuum for 0.5 hours at a temperature lower than 40° C. and a vacuum degree higher than -0.085 MPa to obtain a precursor. Mix the dried product with 1.5g of ammonium oxalate evenly, put it into a muffle furnace at 600°C and burn it for 2 hours, cool, grind and pulverize to obtain powdered hematite-type nano-scale iron oxide red. Tested by SEM, the product particle size of iron oxide red is less than 100nm. in: figure ...

Embodiment 2

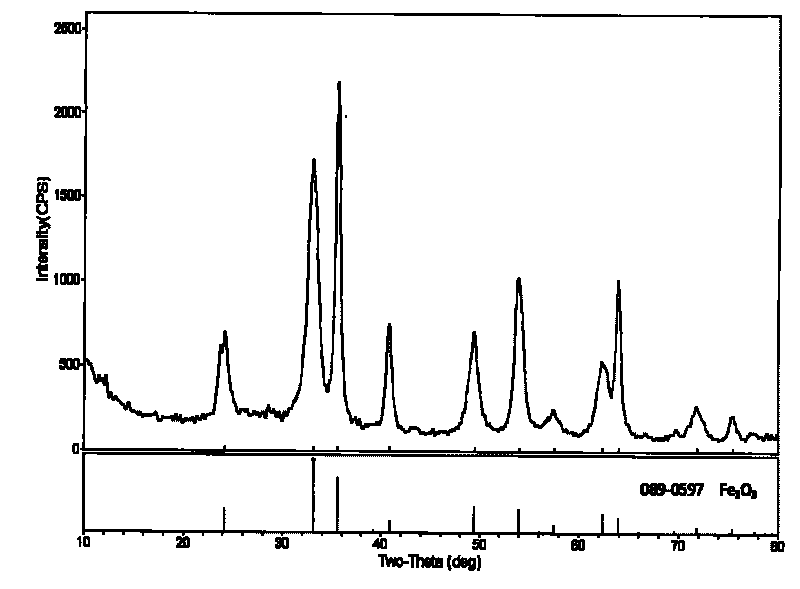

[0024] Dissolve 40g ammonium ferrous sulfate in 100mL deionized water to make Fe 2+ Solution, then mix the mixture of 1g polyethylene glycol and 0.35g sodium dodecylbenzenesulfonate, add sodium hydroxide dropwise under stirring to make the pH 4.0~4.5, then add 100mL (10%) sodium hypochlorite, and control it with sodium hydroxide The pH is 4.0-4.5, the temperature is kept at 27°C, and the reaction is carried out for 45 minutes. After the reaction product settled, it was filtered to obtain a solid, and the solid was vacuum-dried at low temperature for 1 hour to obtain a precursor. Mix the dry product with 1g of ammonium carbonate evenly, put it into a muffle furnace at 700°C and burn for 1.5 hours, cool, grind and pulverize to obtain powdered hematite-type nano-scale iron oxide red. Product is carried out SEM, XRD measurement, shows that its product is consistent with the final product in embodiment 1.

Embodiment 3

[0026] Dissolve 40g ammonium ferrous sulfate in 100mL deionized water to make Fe 2+ solution, then mix 2g of polyvinyl alcohol, add sodium carbonate dropwise under stirring to make the pH 4.0-4.5, then add 10g of sodium chlorate solid, and use sodium carbonate to control the pH to 4.0-4.5, keep the temperature at 29°C, and react for 30 minutes. After the reaction product settled, it was filtered to obtain a solid, and the solid was vacuum-dried at low temperature for 1.5 hours to obtain a precursor. Mix the dry product with 0.5g of ammonium carbamate and ammonium bicarbonate mixture (mass ratio 1:4), put it into a muffle furnace at 800°C and burn for 1 hour, cool, grind and pulverize to obtain powdered hematite nano-scale Iron oxide red. Product is carried out SEM, XRD measurement, shows that its product is consistent with the final product in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com