Preparation method of spherical zirconium silicate nano aggregate powder

A technology of nano-powder and zirconium silicate, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that it is difficult to show the performance advantages of nano-coating, the surface roughness of micron-spherical powder, the influence of Use performance and other issues to achieve the effect of eliminating the introduction of impurities, avoiding hard agglomeration, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

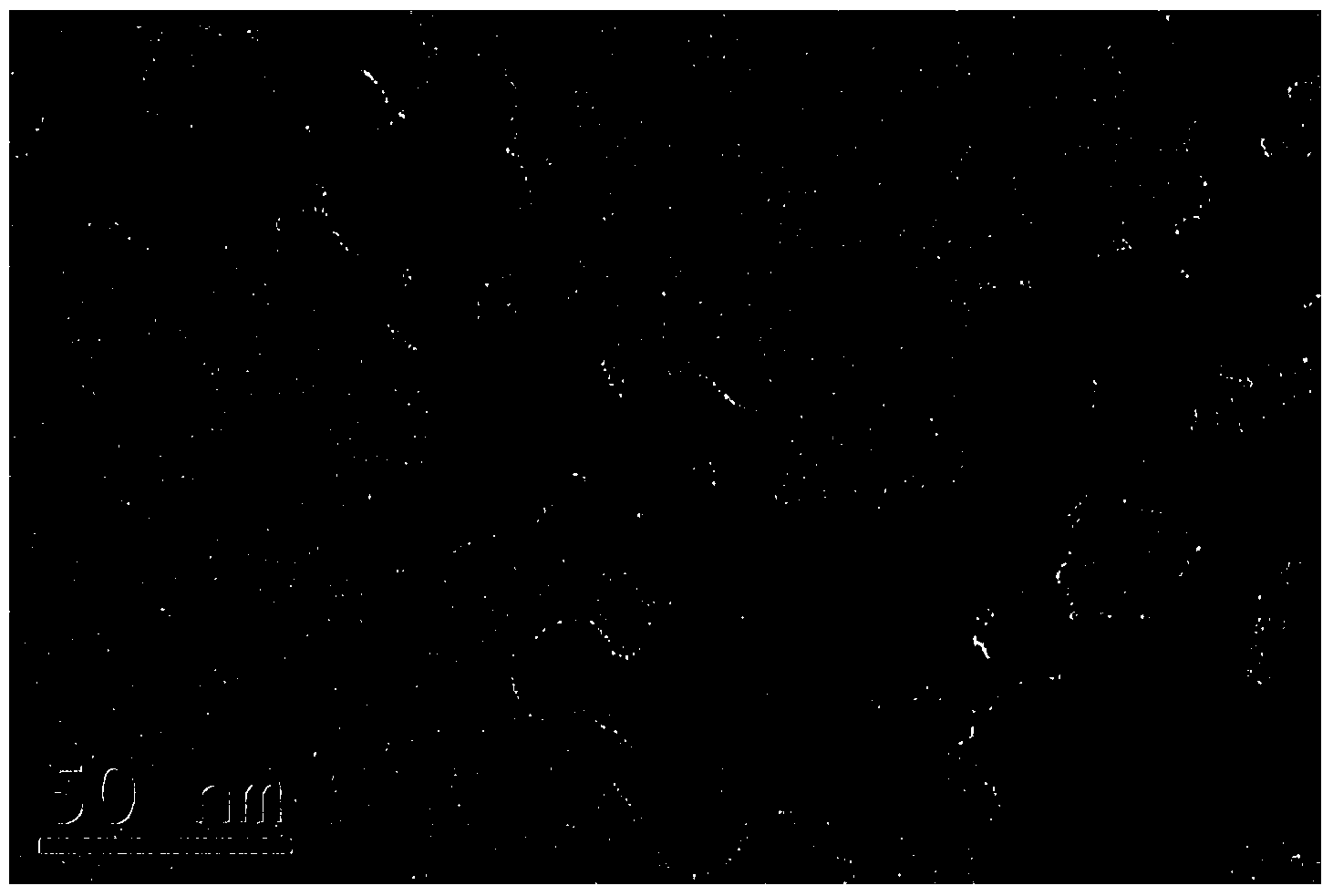

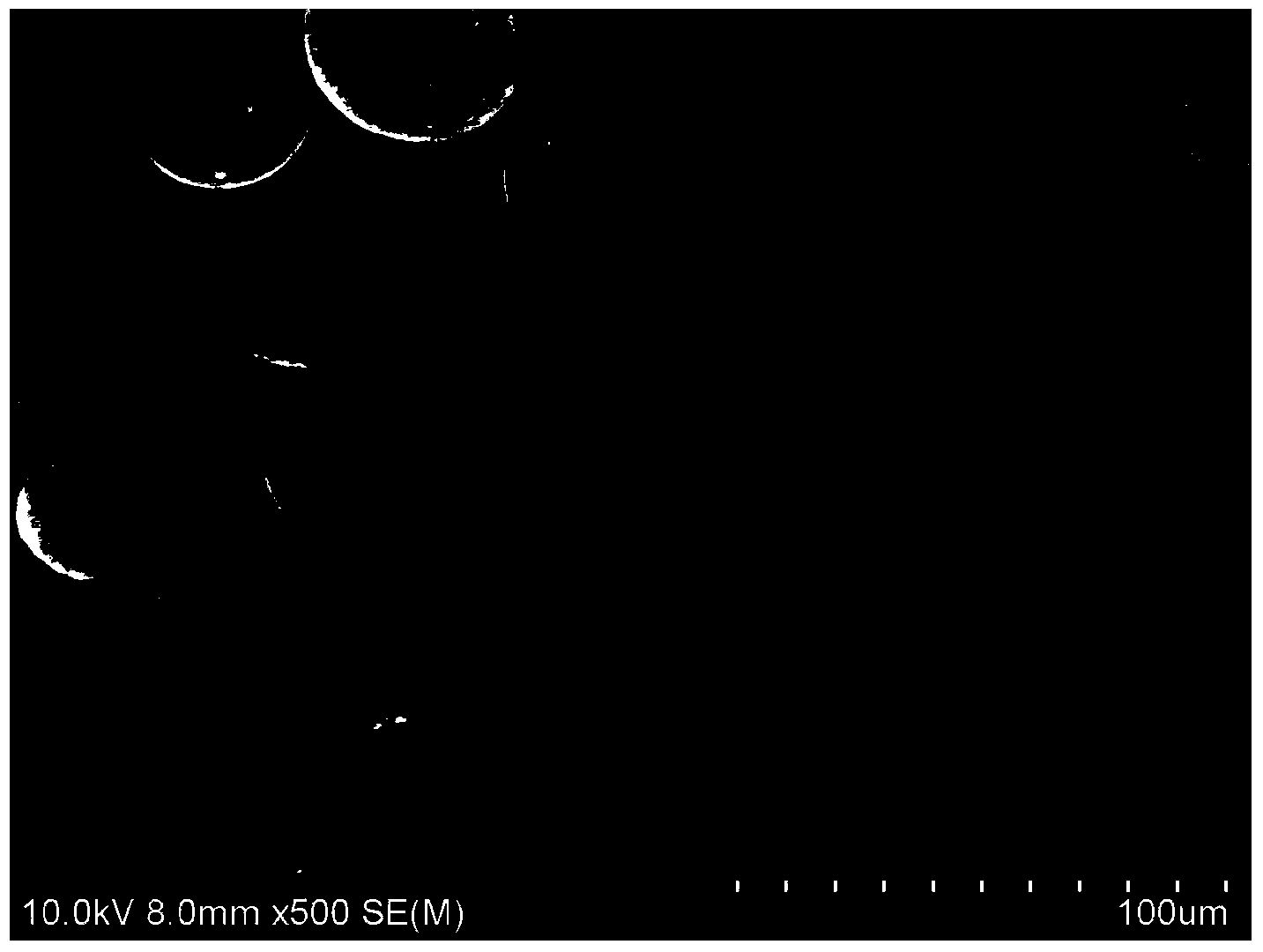

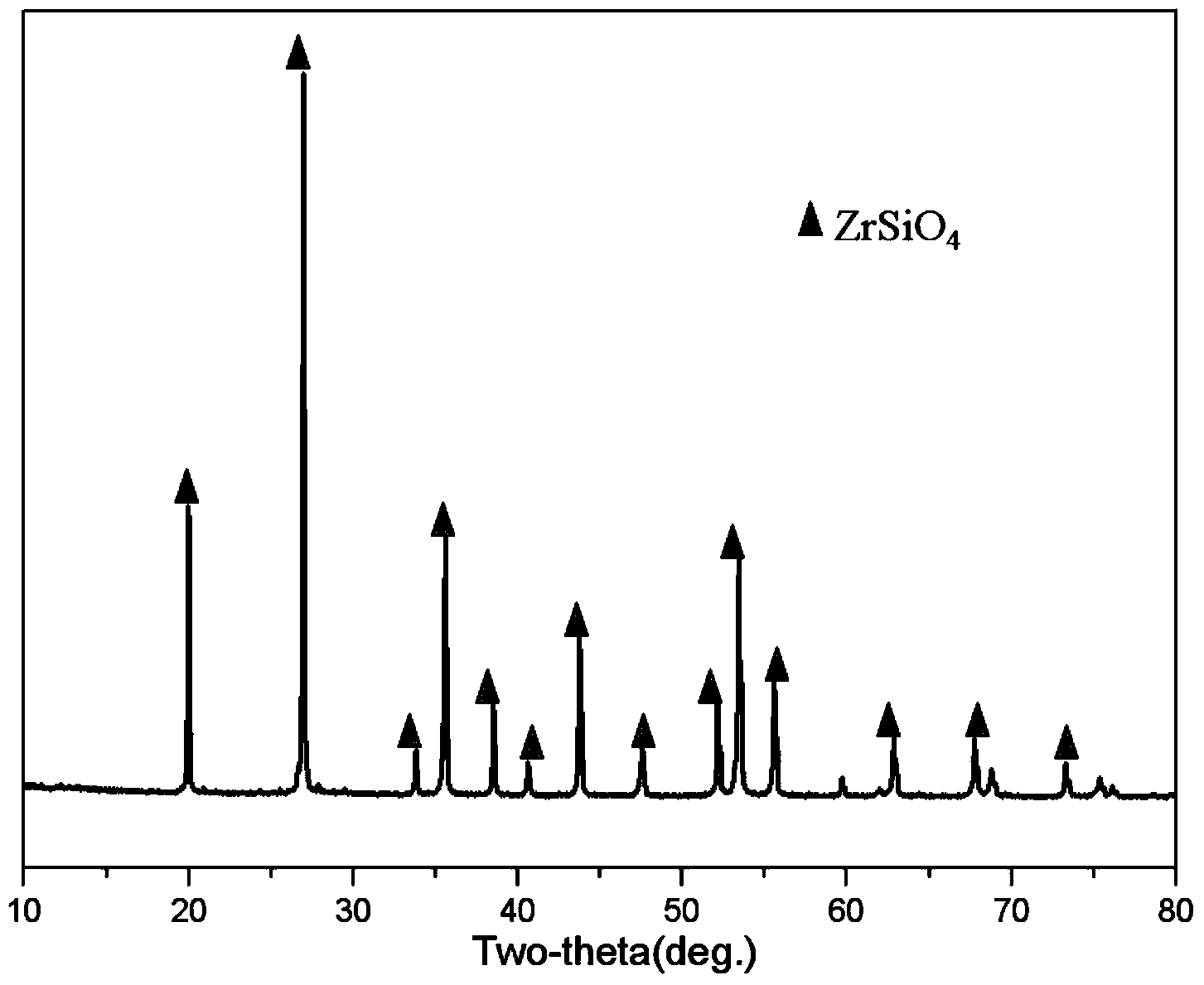

[0033] (1) 31.70g zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 O), 34.97g sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 O) Mix it with 500g deionized water as a raw material, separate the precipitate, wash it with deionized water, and dry it in an oven at 100°C, and the obtained powder is the precursor;

[0034] (2) Add 8.26g of mineralizing agent sodium fluoride (NaF) to 18g of precursor and mix with 1L of deionized water, put it into a 1.5L barrel reactor for hydrothermal reaction, the reaction time is 4h, and the reaction temperature is 180 ℃, the impurity-containing zirconium silicate powder is obtained, and the powder is softly agglomerated at this time;

[0035] (3) Mix 18g of impurity-containing zirconium silicate powder obtained in step (2) with 4L of deionized water, use an inorganic membrane separator to wash and filter to obtain a concentrated slurry, and the operating pressure of the inorganic membrane separator is 0.2MPa~0.25MPa, the washing temperatur...

Embodiment 2

[0046] (1) 41.98g of zirconium oxychloride octahydrate and 24.69g of sodium metasilicate nonahydrate were used as raw materials to make a mixed solution with 650g of deionized water. The precipitate was separated, washed with deionized water, and dried in an oven at 100°C. The obtained powder was Precursor.

[0047] (2) Add 10.94g of mineralizing agent sodium fluoride to 24g of precursor and mix with 1L of deionized water, put it into a 1.5L barrel reactor for hydrothermal reaction, the reaction time is 10h, and the reaction temperature is 380℃, the obtained Zirconium silicate powder with impurities, at this time, the powder is softly agglomerated;

[0048] (3) Mix 24g of impurity-containing zirconium silicate powder obtained in step (2) with 4L of deionized water, use an inorganic membrane separator to wash and filter to obtain a concentrated slurry, and the operating pressure of the inorganic membrane separator is 0.2MPa~0.25MPa, the washing temperature is 70℃~80℃, the memb...

Embodiment 3

[0059] (1) Mix 35.42g of zirconium oxychloride octahydrate and 31.25g of sodium metasilicate nonahydrate as raw materials with 500g of deionized water, separate the precipitate, wash with deionized water, and dry in an oven at 100°C, and the obtained powder is the precursor;

[0060] (2) Add 9.22g of mineralizing agent sodium fluoride and 1L of deionized water to 20g of the precursor, mix it with 1L of deionized water, put it into a 1.5L cylinder reactor for hydrothermal reaction, the reaction time is 6h, and the reaction temperature is 200℃, the obtained Zirconium silicate powder with impurities, at this time, the powder is softly agglomerated;

[0061] (3) Mix 20g of impurity-containing zirconium silicate powder obtained in step (2) with 4L of deionized water, use an inorganic membrane separator to wash and filter to obtain a concentrated slurry, and the operating pressure of the inorganic membrane separator is 0.2MPa~0.25MPa, the washing temperature is 70℃~80℃, the membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com