Preparation method of indium tin oxide nano-powder with controllable crystalline form

A technology of indium tin oxide and indium tin hydroxide, applied in chemical instruments and methods, gallium/indium/thallium compounds, tin oxide, etc. Difficult to disperse and other problems, to achieve the effect of inhibiting powder agglomeration, excellent dispersibility, and avoiding hard agglomeration of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

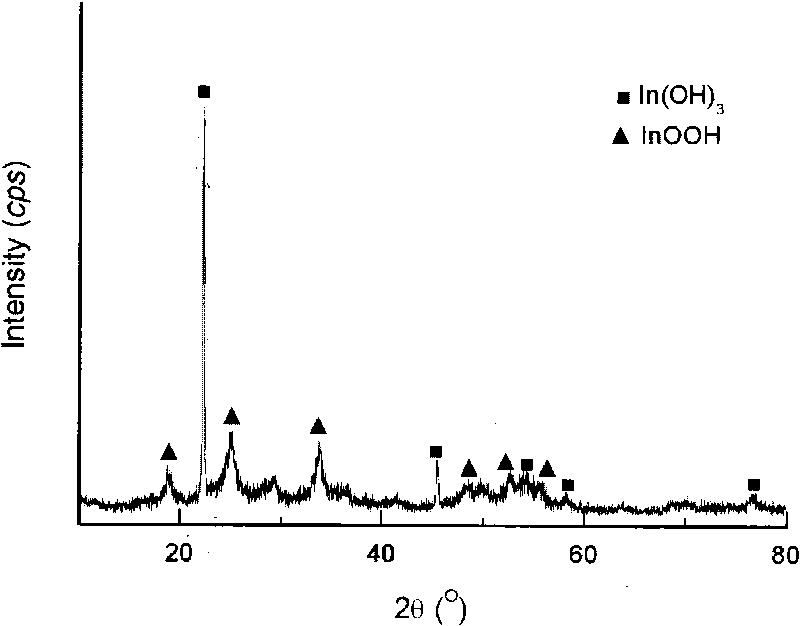

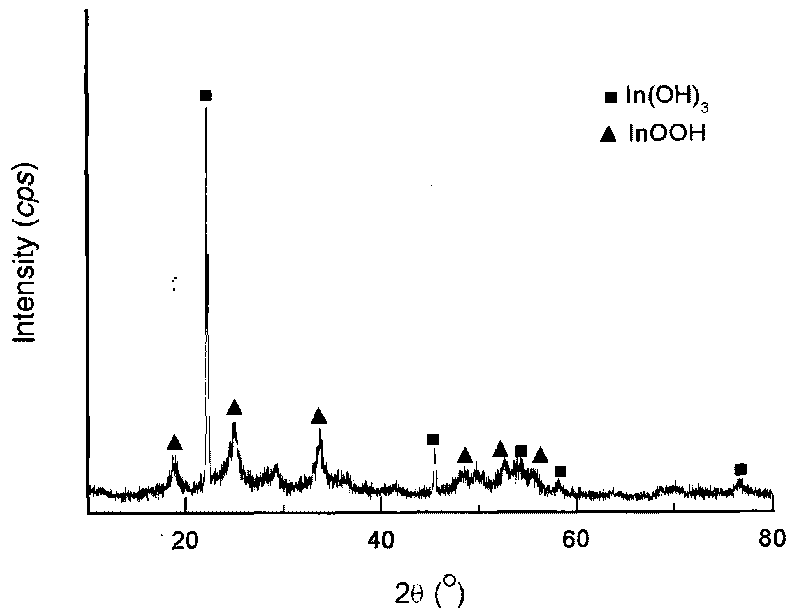

[0018] Take 11g InCl 3 Dissolve in 250ml of deionized water and stir mechanically. After 10 minutes, take out 50ml of the solution, add 1g of anhydrous SnCl 4 , after being completely dissolved, slowly added to the stirring InCl 3 aqueous solution, and placed in a constant temperature water bath for mechanical stirring. Prepare 80 ml of 3M ammonia solution with deionized water, slowly add it to the indium tin solution at room temperature until the pH value of the solution reaches 3.0, then raise the temperature of the water bath to 70°C, and continue to add the ammonia solution until the pH is 7.0 as of now. After the white precipitate was separated, it was stirred and washed in 200ml of 60°C distilled water and 60°C ethanol for 1 hour respectively. After suction filtration, it was dispersed with absolute ethanol, dried, and sieved to obtain the precursor powder. The XRD structure analysis results show that the precursor powder contains two phases: In(OH) 3 and InOOH, whe...

Embodiment 2

[0020] Take 1.5g of precursor powder and put it in a porcelain boat, and put it into a tubular resistance furnace with a glass three-way-quartz tube furnace. Turn on the three-way switch, and calcinate at 800°C for 1h in an air atmosphere, and the heating rate is 10°C / min, yellow-green ITO powder was obtained. The TEM observation results of the powder showed that the ITO grain morphology completely inherited the rod-like structure and high dispersion characteristics of the precursor, and the grain size was slightly smaller than the precursor. The grain is a polycrystal composed of many small grains with a size of 20-30nm closely packed, and the aspect ratio is 3-4.

Embodiment 3

[0022] Take 1.5g of precursor powder and put it in a porcelain boat, and put it into a tubular resistance furnace with a glass tee-quartz tube furnace. Close the glass tee at one end of the quartz tube, connect the three-way switch at the other end to a vacuum pump, reduce the air pressure in the quartz tube to below 1 Torr, then start the calcination heating program at a heating rate of 10°C / min, and calcine at 800°C for 1 hour in vacuum to obtain Yellow-green ITO powder. The powder TEM morphology observation results show that the ITO grains are equiaxed polyhedral grains, the grain size is between 40-80nm, and there is no hard agglomeration between the grains.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com