Scandium-cerium co-doped zirconium oxide powder and preparation method thereof

A technology of zirconia powder and powder, which is applied in the field of solid oxide fuel cells, can solve the problems such as unsuitable casting process, and achieve the effects of good sintering, good dispersion and good sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

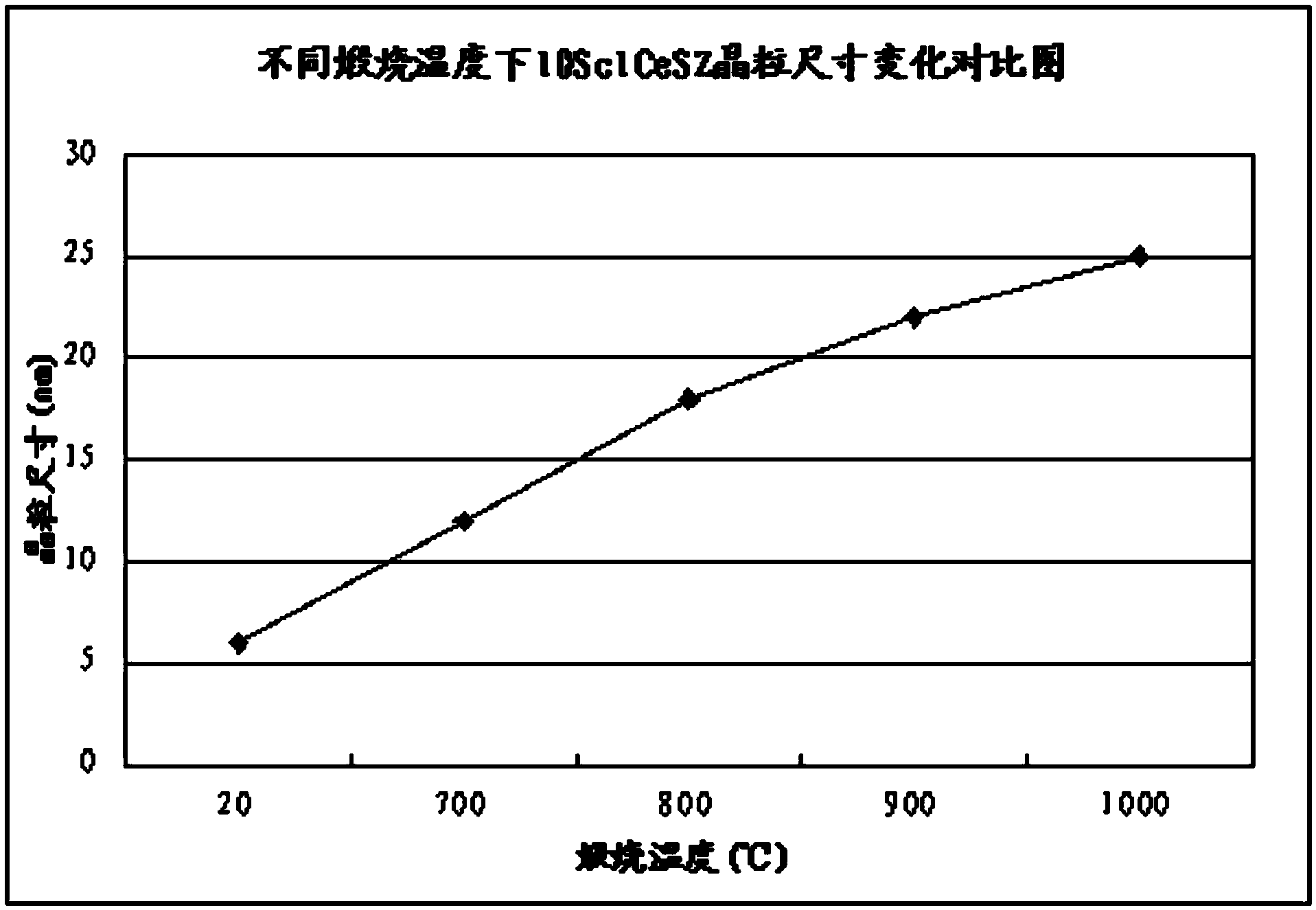

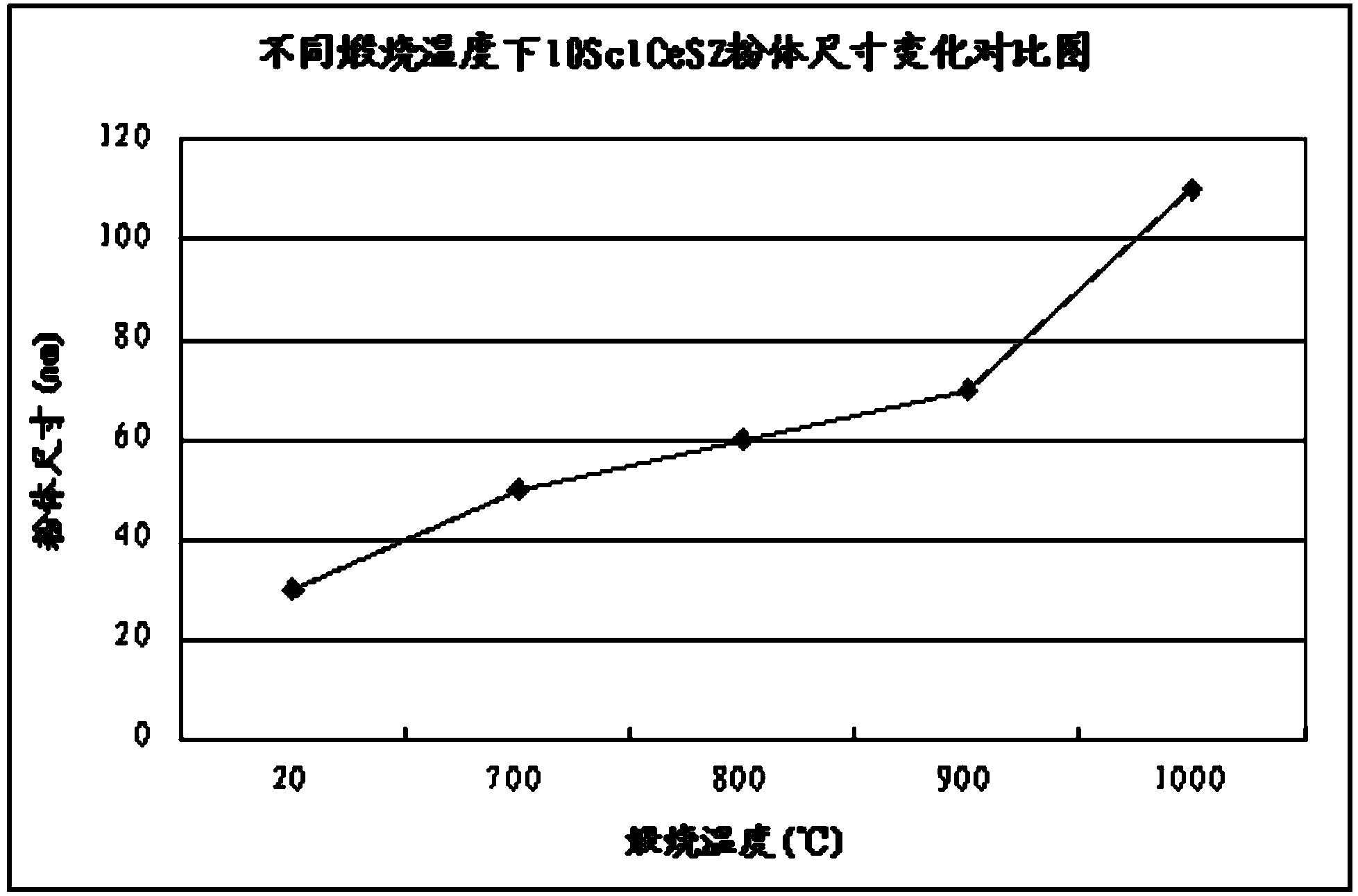

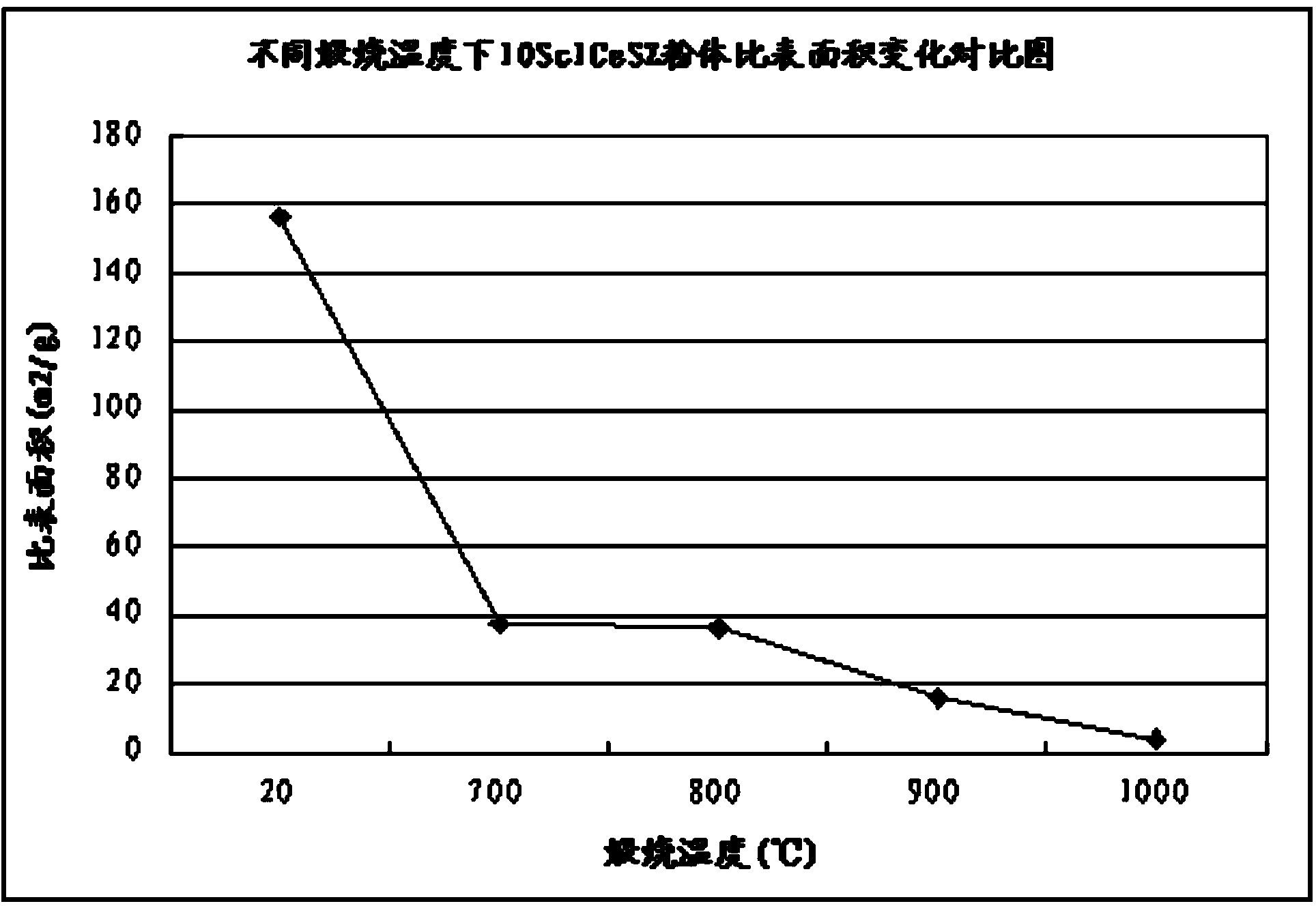

[0037] Preparation of mixed salt solution: the chemical composition of the synthesized 10Sc1CeSZ powder is (Sc 2 o 3 )0.1(CeO 2 )0.01 (ZrO 2 )0.89, take by weighing 2290.37g of ZrOCl according to its composition requirements 2 ·8H 2 O, 34.68g of Ce(NO 3 ) 3 ·xH 2 O and 369.02g of Sc(NO 3 ) 3 Dissolved in 44L water, making ZrO 2+ The ion concentration is 0.1mol / L, and PEG400 and PEG6000 are added therein as (non-ionic) surfactants, the mass of which is 1% and 0.5% of the mass of the generated hydroxide precursor, and stirred to fully dissolve it.

Embodiment 2

[0039] Precipitant solution preparation: according to ZrOCl 2 ·8H 2 O, Ce(NO 3 ) 3 ·xH 2 O and Sc(NO 3 ) 3 1.5 times of the required ammonia stoichiometric ratio for precipitation reaction takes by weighing 2.2L concentrated ammonia water (25%-28%, density 0.9g / cm 3 ), add surfactant ammonium polyacrylate (NH 4 PPA), stir and mix evenly, then the concentration of ammonia water is diluted to about 2.5%.

Embodiment 3

[0041] Formation of precursor precipitation: under strong stirring, slowly pour the mixed salt solution obtained in Example 1 into the precipitant solution obtained in Example 2, and continuously increase the stirring speed to prevent uneven mixing of the solution, and the precipitation reaction ends Then continue to stir at high speed for 0.5h to ensure uniform mixing, so that the precipitation reaction is more complete, and then stand for aging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com