Method for preparing nano iron oxide red

A technology of iron oxide red and nanometer, which is applied in the direction of fibrous fillers, can solve the problems of difficult control of particle size and shape, complex process, long production cycle, etc., and achieve easy control of process parameters, simple preparation process and good dispersion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

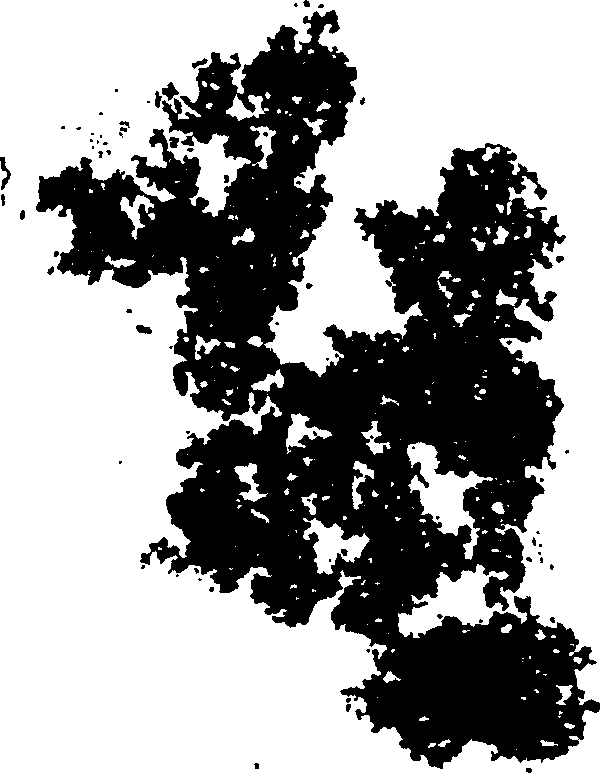

[0032] The preparation process of this embodiment is as follows Figure 7 shown. 31.8g anhydrous Na 2 CO 3 Dissolve in 300ml of deionized water to make lye, add 0.05ml of ethyl acetate under vigorous stirring (600 rpm) to make the solution evenly mixed, then add 300ml of FeCl with a concentration of 0.1mol / l under continuous stirring 3 ·6H 2 O solution to form a gel, then add 30ml to a concentration of 1×10 -4 mol / l sodium dihydrogen phosphate solution, the PH value of the mixed solution is 9; aging at 85°C for 5 minutes to obtain a red suspension, which is then centrifuged with a centrifugal pump, washed 3 times with deionized water, and heated at 25°C After drying for 1.5 hours, the spherical α-Fe with an average particle size of 60nm was obtained after grinding. 2 o 3 Particles, the grain size is close to monodisperse, and its TEM picture is shown in image 3 .

Embodiment 2

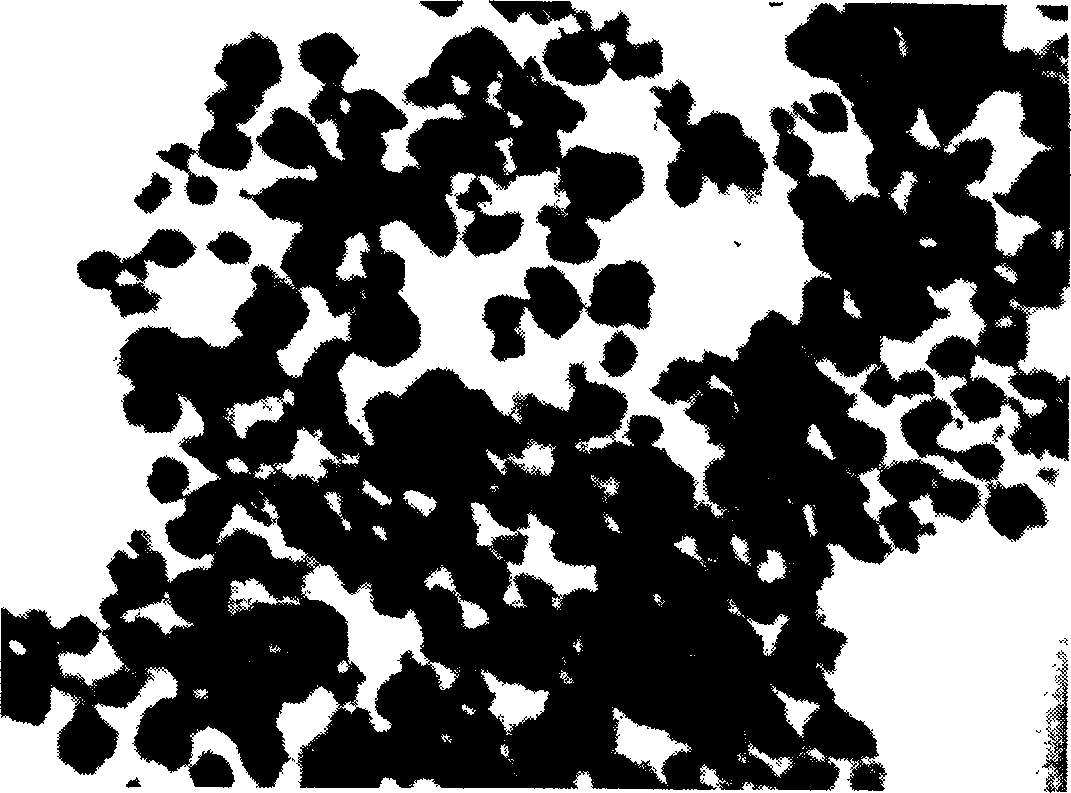

[0034] The preparation process of this embodiment is as follows Figure 7 shown. 95g anhydrous NaHCO 3 Dissolve in 300ml of deionized water to make lye, then add 0.3g of citric acid under stirring condition (1000 rpm) to make the solution fully mixed. FeSO 4 ·7H 2 O (0.3mol / l) solution 1000ml was oxidized in the air for 0.5 hours, and the oxidized product was added to the above mixture to form a gel under continuous stirring, and then 3000ml was added to a concentration of 1×10 -3 mol / l sodium dihydrogen phosphate solution, the PH value of the mixed solution is 8; aged at 110°C for 20 minutes to obtain a red suspension, which was centrifuged with a centrifugal pump and washed 5 times with deionized water. Cubic α-Fe with an average particle size of 42 nm was obtained after drying at ℃ for 3 hours. 2 o 3 Particles, the grain size is close to monodisperse, and its TEM picture is shown in Figure 4 .

Embodiment 3

[0036] The preparation process of this embodiment is as follows Figure 7 shown. 45mlNH 3 ·H 2 O (25%, mass ratio) and 11ml of acetic anhydride are fully stirred (1100 rpm) and mixed, and 300ml of Fe(NO 3 ) 3 9H 2 O solution to form a gel, then add 60ml to a concentration of 1×10 -4 mol / l sodium dihydrogen phosphate solution, the pH value of the mixed solution is 10; aged at 105°C for 20 minutes, a red suspension was obtained, which was centrifuged with a centrifugal pump, and then washed 3 times with deionized water. Cubic α-Fe with an average particle size of 35 nm was obtained after drying at ℃ for 1.5 hours. 2 o 3 Particles, the grain size is close to monodisperse, and its TEM picture is shown in Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com