Silver paste used for positive electrodes of solar batteries and grid lines, preparation method thereof and solar battery containing same

A technology for solar cells and front electrodes, applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency, difficult to pass through the wire mesh, and difficult to effectively transmit the current of the cell, so as to improve the photoelectric conversion efficiency, reduce the degree of agglomeration, and achieve excellent photoelectric conversion efficiency. The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

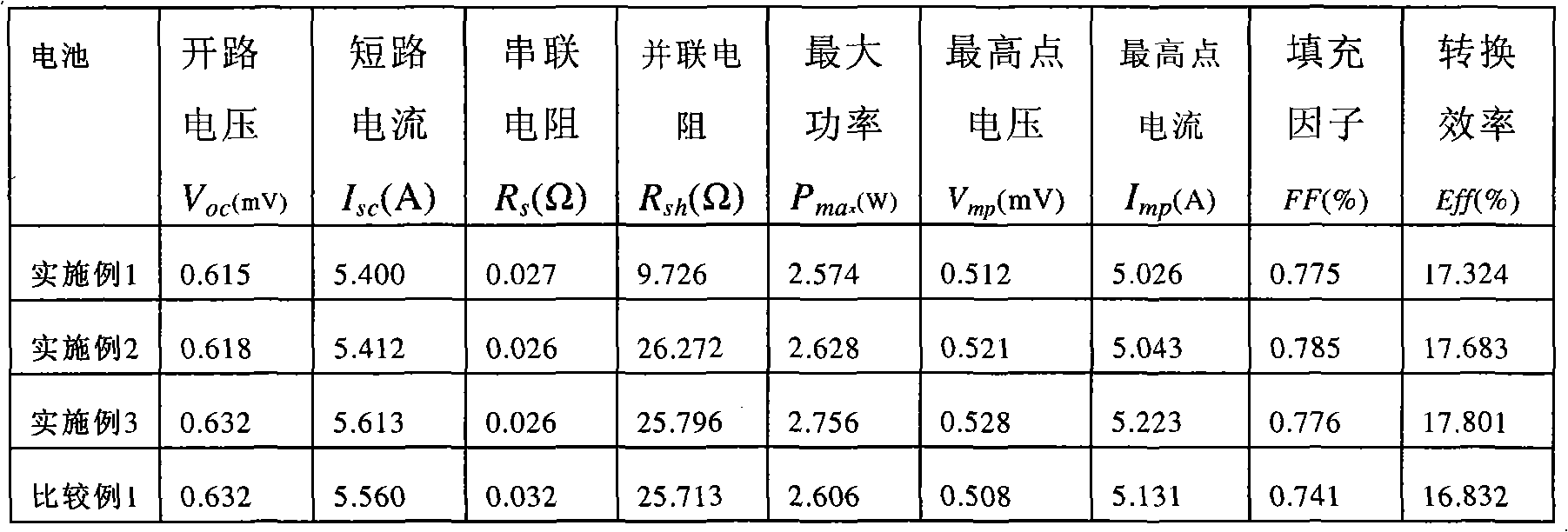

Embodiment 1

[0029] The preparation of the silver paste for the front electrode of the solar cell and the grid wire comprises the following steps:

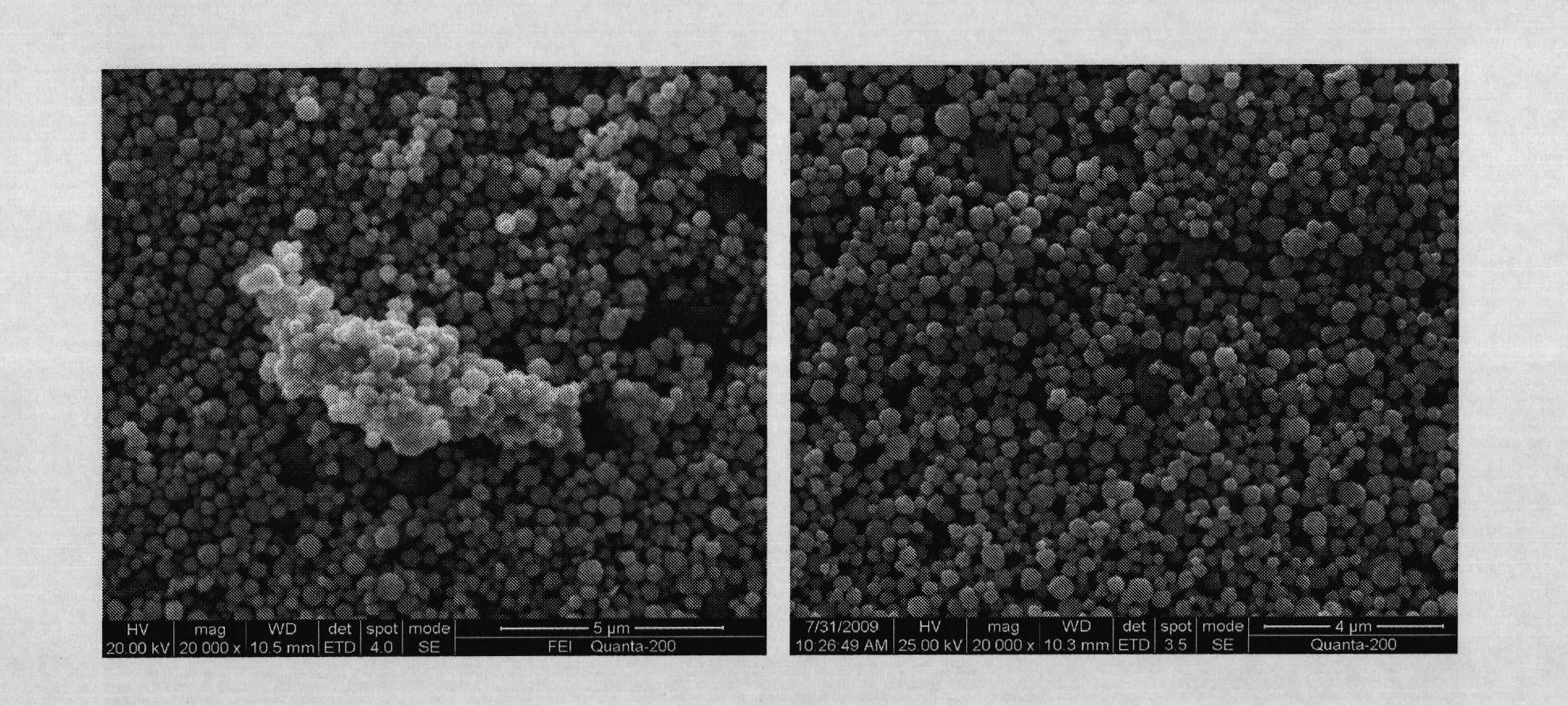

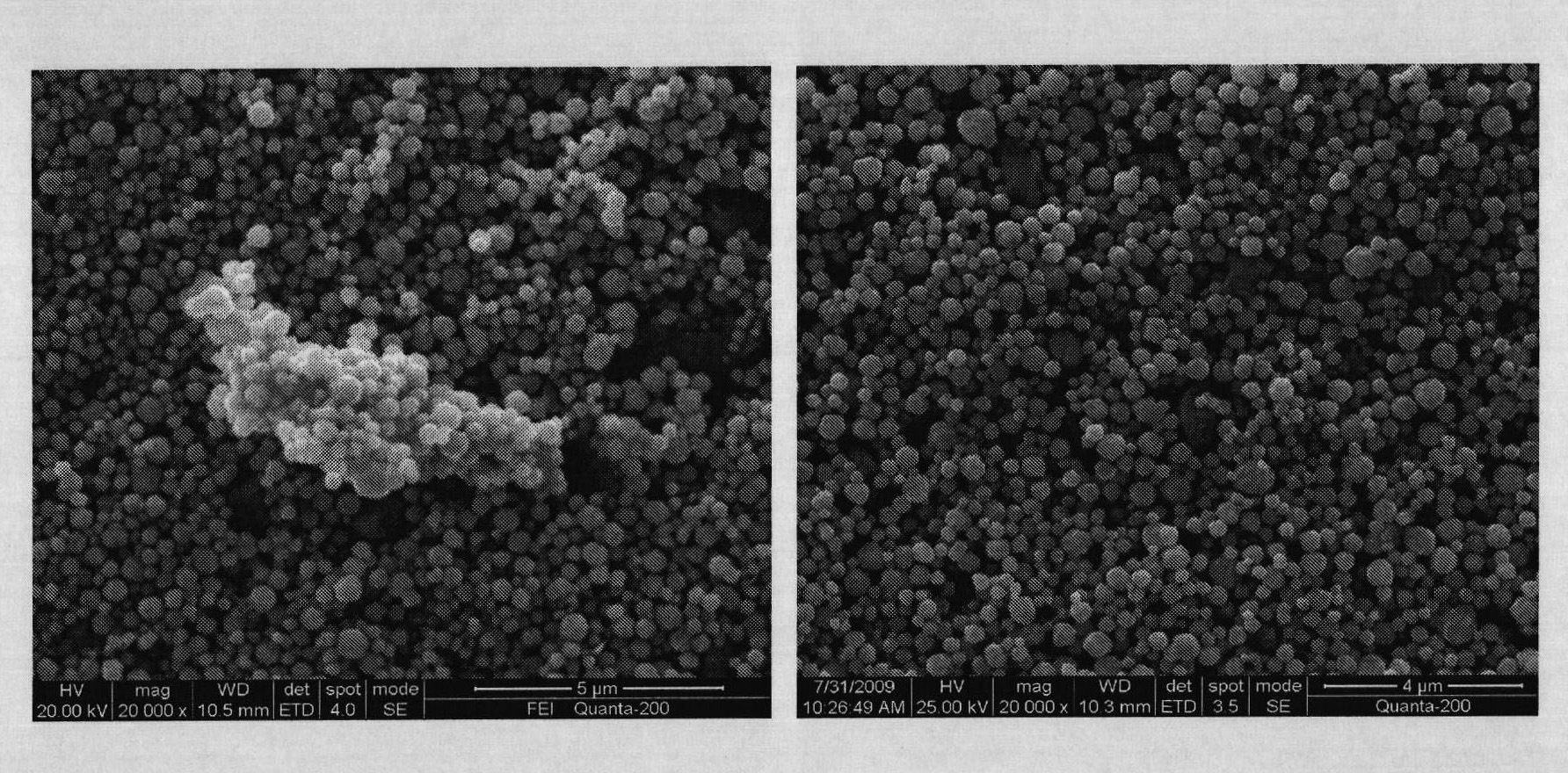

[0030] 1. Prepare highly dispersed ultrafine silver powder slurry by chemical liquid phase reduction method: Silver nitrate is prepared into 20L of 0.15mol / L solution, and its pH value is adjusted to 7 with ammonia water and nitric acid to form silver ammonia solution, and then The reducing agent hydrazine hydrate is made into 20L of a solution of 0.30mol / L, then 100g of the dispersing agent polyvinylpyrrolidone is added to the reducing agent solution, and the pH value is adjusted to 8 with ammonia and nitric acid. Add it dropwise into the reducing agent and dispersant solution at a rate of 2L / min under electric stirring, and react for another 10 minutes after the dropwise addition to obtain a highly dispersed ultrafine silver powder slurry;

[0031] 2. Separating the superfine silver powder slurry through solid-liquid separation to obtain wet...

Embodiment 2

[0036] The preparation of the silver paste for the front electrode of the solar cell and the grid wire comprises the following steps:

[0037] 1. Prepare highly dispersed ultrafine silver powder slurry by chemical liquid phase reduction method: Silver nitrate is prepared into 20L of 0.15mol / L solution, and its pH value is adjusted to 7 with ammonia water and nitric acid to form silver ammonia solution, and then The reducing agent formaldehyde is made into 20L of the solution of 0.30mol / L, then add 100g of dispersing agent polyvinyl alcohol in the reducing agent solution, adjust its pH value to 8 with ammonia water and nitric acid, put the silver ammonia solution in the electric motor at 300 rpm Add dropwise to the reducing agent and dispersant solution at a rate of 2L / min under stirring, and react for another 10 minutes after the dropwise addition to obtain a highly dispersed ultrafine silver powder slurry;

[0038] 2. Separating the superfine silver powder slurry through soli...

Embodiment 3

[0043] The preparation of the silver paste for the front electrode of the solar cell and the grid wire comprises the following steps:

[0044] 1. Prepare highly dispersed ultrafine silver powder slurry by chemical liquid phase reduction method: Silver nitrate is prepared into 20L of 0.15mol / L solution, and its pH value is adjusted to 7 with ammonia water and nitric acid to form silver ammonia solution, and then The reducing agent ascorbic acid is made into 20L of 0.30mol / L solution, and then 100g of dispersing agent gelatin is added to the reducing agent solution, and the pH value is adjusted to 8 with ammonia water and nitric acid, and the silver ammonia solution is stirred under electric stirring at 300 rpm Add it dropwise to the reducing agent and dispersant solution at a dropping speed of 2L / min, and react for another 10 minutes after the dropping to obtain a highly dispersed ultrafine silver powder slurry;

[0045] 2. Separating the superfine silver powder slurry through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com