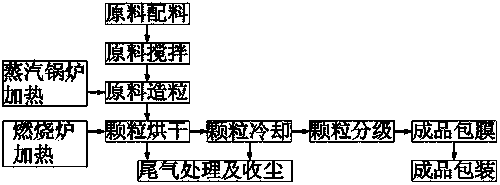

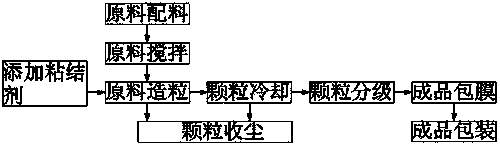

Drying-free granulating process of composite fertilizer

A compound fertilizer, non-drying technology, applied in the direction of fertilizer form, fertilization device, fertilizer mixture, etc., can solve the problems of increased control device cost, fast chemical reaction speed, uneven heat distribution, etc., to reduce equipment cost and simplify production process process, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment one, if formulating the novel compound fertilizer that formula is that N-P-K is 24-12-10, then in the described raw material compounding procedure link, used raw material is the urea of 46%N, 11%N44%P 2 o 5 Monoammonium phosphate, 60%K 2 O potassium chloride, its corresponding number of parts is 47 parts, 23 parts, 20 parts successively; 3 PO 4 Phosphoric acid solution, wherein the number of parts of magnesium oxide powder is 8 to 15, the number of parts of phosphoric acid solution is 3 to 6, and the optimization scheme is that the number of parts of magnesium oxide powder is 10, and the number of parts of phosphoric acid solution is 4.

Embodiment 2

[0023] Embodiment two, if formulating formula is that N-P-K is the novel compound fertilizer of 20-15-10, in the described raw material compounding procedure link, used raw material is the urea of 46%N, 11%N44%P 2 o 5 Monoammonium phosphate, 57%K 2 O potassium chloride, its corresponding number of parts is 35 parts, 35 parts, 17 parts successively; 3 PO 4 Phosphoric acid solution, wherein the number of parts of magnesium oxide powder is 10 to 17, the number of parts of phosphoric acid solution is 3 to 6, and the optimization scheme is that the number of parts of magnesium oxide powder is 13, and the number of parts of phosphoric acid solution is 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com