Environment-friendly heat-resistant precoated sand as well as preparation method and application thereof

A coated sand, environmentally friendly technology, applied in foundry molding equipment, molds, cores, etc., can solve problems such as iron tailings coated sand that has not been reported yet, achieve delaying thermal decomposition, and have obvious cost advantages. , the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The embodiment of the present invention provides an environment-friendly heat-resistant coated sand.

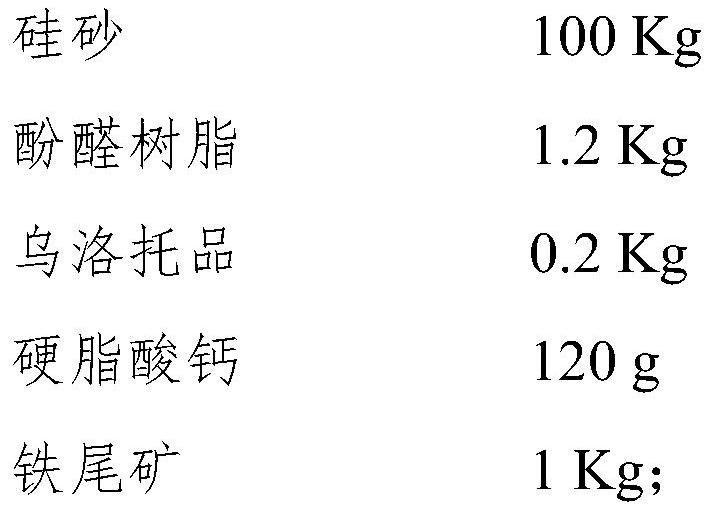

[0051] 1. Composition

[0052]

[0053] 2. Preparation method

[0054] Specifically include the following steps:

[0055] S1. Weigh the silica sand and place it in the sand mixing bucket, and heat it to 150°C;

[0056] S2. Weigh the phenolic resin, add it into the sand mixing tank with heated silica sand in step S1, and stir for 25 seconds;

[0057] S3. Accurately weigh urotropine, add it to 3 times the mass of water and mix to obtain the urotropine aqueous solution, then add the urotropine aqueous solution into the sand mixing bucket in S2, and stir for 35s;

[0058]S4. Accurately weigh the pretreated iron tailings, add to the sand mixing bucket in S3, and stir for 12s;

[0059] S5. Accurately weigh the calcium stearate, add it into the sand mixing bucket in S4, and stir for 50 seconds.

Embodiment 2

[0061] The embodiment of the present invention provides an environment-friendly heat-resistant coated sand.

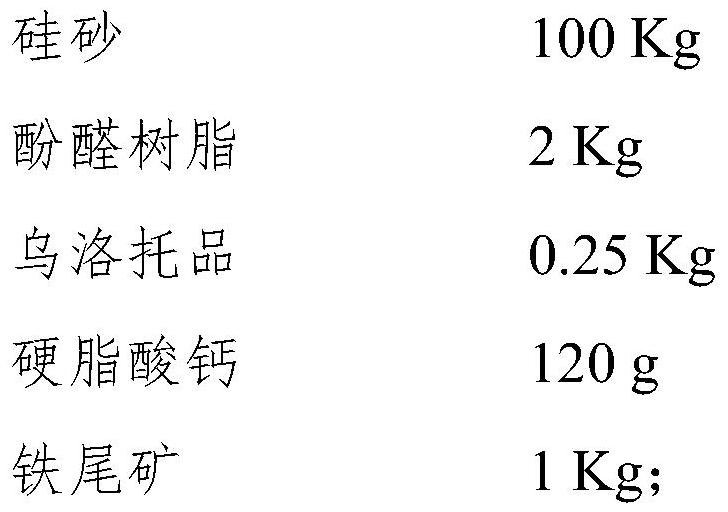

[0062] 1. Composition

[0063]

[0064] 2. Preparation method

[0065] Specifically include the following steps:

[0066] S1. Weigh the silica sand and place it in the sand mixing bucket, and heat it to 150°C;

[0067] S2. Weigh the phenolic resin, add it into the sand mixing tank with heated silica sand in step S1, and stir for 25 seconds;

[0068] S3. Accurately weigh urotropine, add it to 3 times the mass of water and mix to obtain the urotropine aqueous solution, then add the urotropine aqueous solution into the sand mixing bucket in S2, and stir for 35s;

[0069] S4. Accurately weigh the pretreated iron tailings, add to the sand mixing bucket in S3, and stir for 12s;

[0070] S5. Accurately weigh the calcium stearate, add it into the sand mixing bucket in S4, and stir for 50 seconds.

Embodiment 3

[0072] The embodiment of the present invention provides an environment-friendly heat-resistant coated sand.

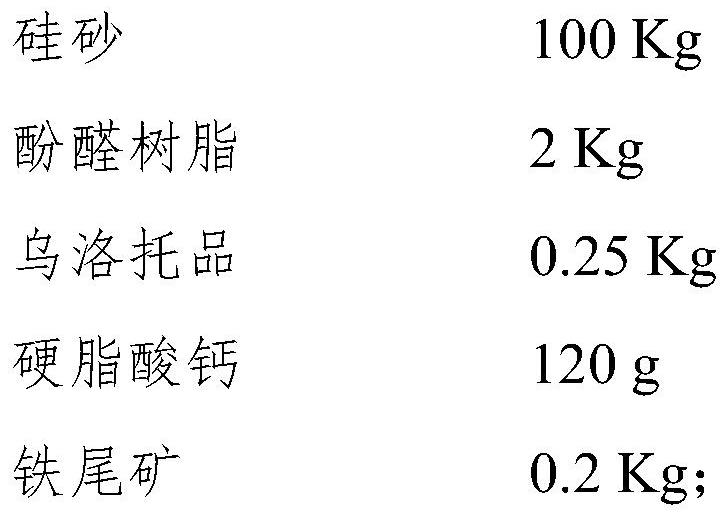

[0073] 1. Composition

[0074]

[0075] 2. Preparation method

[0076] Specifically include the following steps:

[0077] S1. Weigh the silica sand and place it in the sand mixing bucket, and heat it to 150°C;

[0078] S2. Weigh the phenolic resin, add it into the sand mixing tank with heated silica sand in step S1, and stir for 25 seconds;

[0079] S3. Accurately weigh urotropine, add it to 3 times the mass of water and mix to obtain the urotropine aqueous solution, then add the urotropine aqueous solution into the sand mixing bucket in S2, and stir for 35s;

[0080] S4. Accurately weigh the pretreated iron tailings, add to the sand mixing bucket in S3, and stir for 12s;

[0081] S5. Accurately weigh the calcium stearate, add it into the sand mixing bucket in S4, and stir for 50 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com