A high-gloss process for charging interface shells of 3c products

A charging interface and process technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as increased cost, dimensional fluctuations, cumulative tolerances of manufacturing processes, etc., to reduce product production costs and improve dimensional stability , The effect of reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

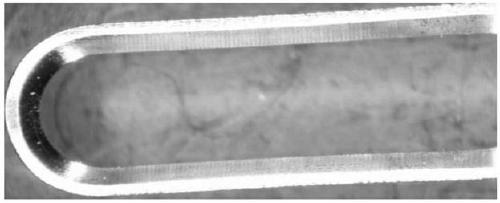

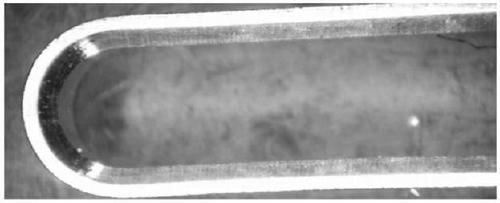

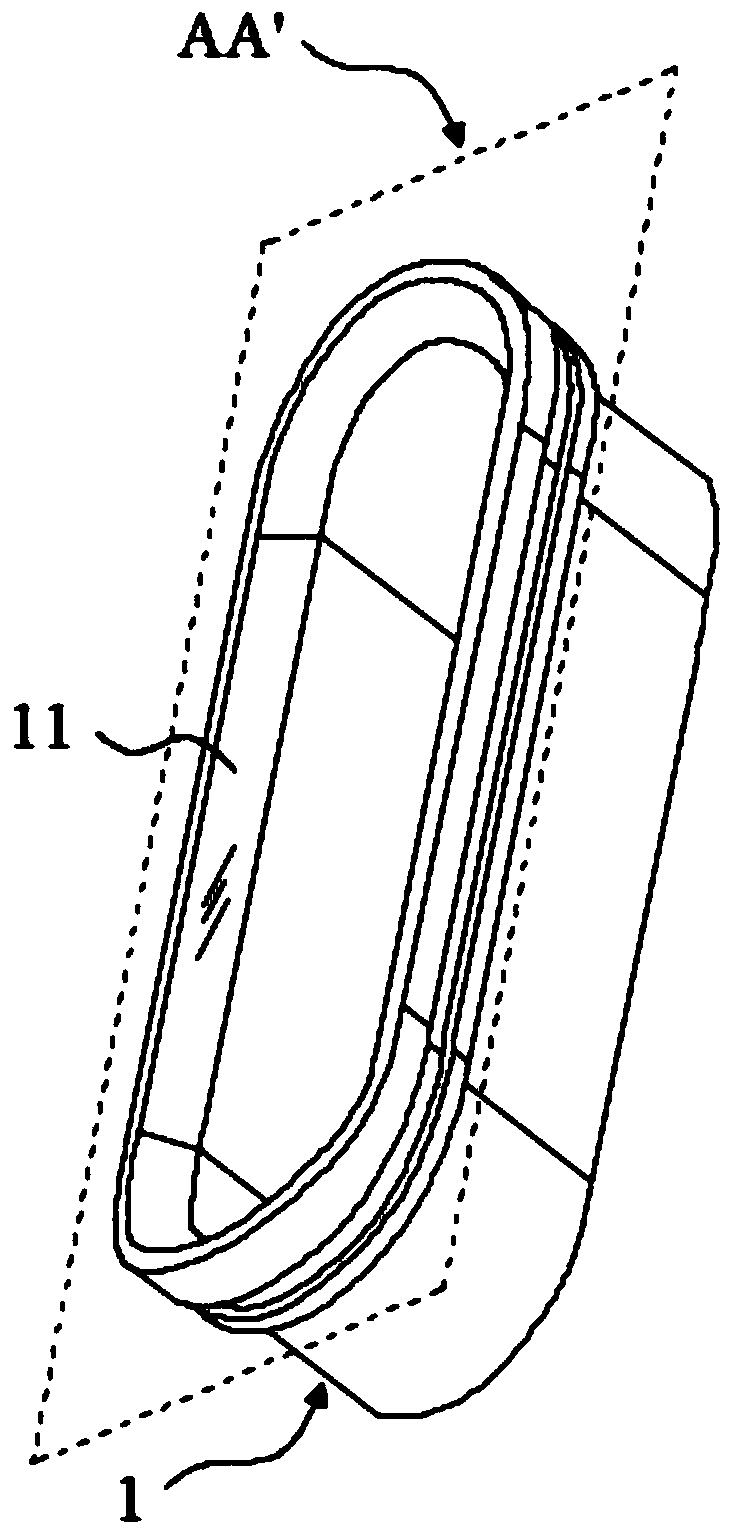

[0065] Add 6kg of spherical chrome corundum with a specification of Φ7mm and charging interface shell 1 formed by 2400 CNC equipment into the grinding barrel of the rolling grinder, and rotate at a constant speed of 1400 rpm for 3 minutes. After the ground charging interface case 1 is cleaned, dried and sand-blasted, the above-mentioned charging interface case 1 and 6 kg of spherical zirconia grinding stones with a specification of Φ0.8 mm are added to the grinding barrel of the rolling mill together to Rotate at 1700 rpm for 5 min. After grinding, the obtained charging interface case 1 is cleaned and dried, and finally a finished charging interface case 1 with a high-gloss and high-gloss surface 11 is obtained.

Embodiment 2

[0067] Add 6kg of spherical chrome corundum with a specification of Φ8mm and charging interface shell 1 formed by 3000 CNC numerical control equipment into the grinding barrel of the rolling grinder, and rotate it at a speed of 1500 rpm for 4 minutes. After the ground charging interface case 1 has been cleaned, dried and sand-blasted, the above-mentioned charging interface case 1 and 6 kg of spherical zirconia grinding stones with a specification of Φ1 mm are added to the grinding barrel of the rolling grinder, and the grinding process is performed at 1800 rpm. Rotate evenly for 8 minutes at a speed of 1 / min. After grinding, the obtained charging interface case 1 is cleaned and dried, and finally a finished charging interface case 1 with a high-gloss and high-gloss surface 11 is obtained.

Embodiment 3

[0069] Add 6kg of spherical chrome corundum with a specification of Φ9mm and the charging interface shell 1 formed by 3600 CNC numerical control equipment into the grinding barrel of the rolling grinder, and rotate it at a speed of 1600 rpm for 5 minutes. After the ground charging interface case 1 has been cleaned, dried and sand-blasted, the above-mentioned charging interface case 1 and 6 kg of spherical zirconia grinding stones with a specification of Φ1.2 mm are added to the grinding bucket of the rolling mill to Rotate evenly for 10 minutes at a speed of 1900 rpm. After grinding, the obtained charging interface case 1 is cleaned and dried, and finally a finished charging interface case 1 with a high-gloss and high-gloss surface 11 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com