A rechargeable zinc-manganese battery and a preparation method thereof

A zinc-manganese battery and battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems affecting battery cycle stability and rate performance, the potential drop of positive manganese dioxide material rapidly, and adverse battery performance. The synthesis process is simple and feasible, the effect of increasing contact and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

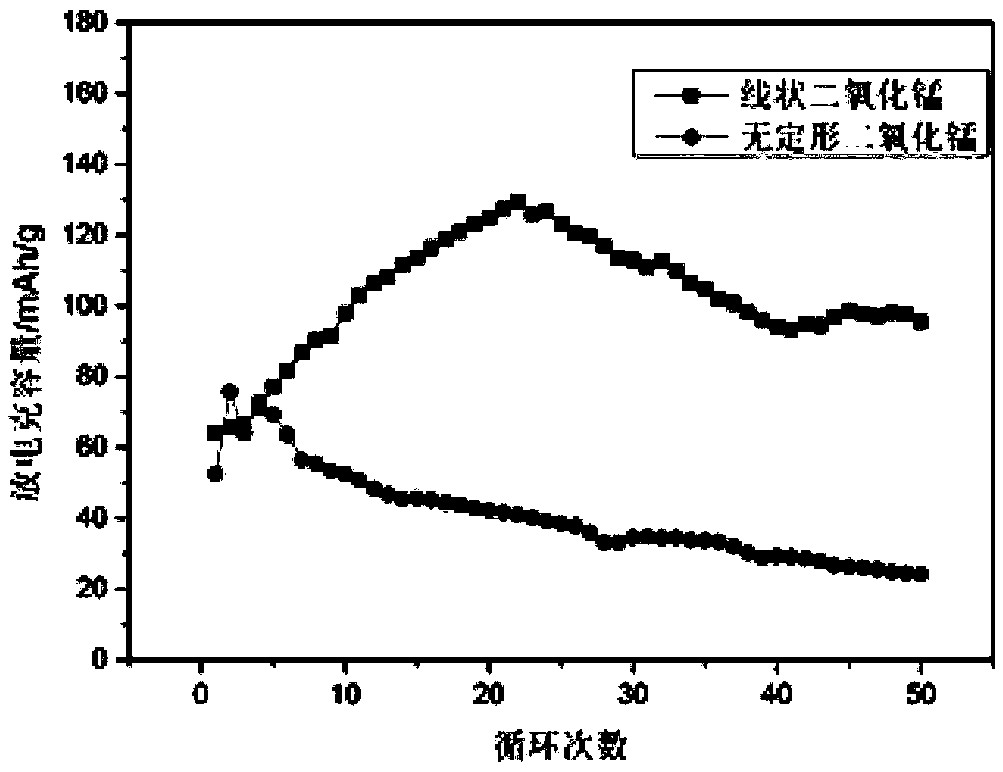

[0054] The positive electrode active material is prepared as follows: Weigh potassium permanganate and manganese sulfate hydrate with a molar ratio of 1:1, dissolve in 50ml deionized water, stir until completely dissolved, transfer to a hydrothermal kettle, then transfer to an oven, and heat up The rate is 5-10°C / min, the temperature is raised to 120-180°C, and kept for 4-12h, then naturally cooled to room temperature, the obtained material is washed several times and dried. Under the air atmosphere, calcine at high temperature for 1-4 hours, control the calcination temperature at 400-600° C., and control the heating rate at 5-8° C. / min. Synthesis of α-MnO by this method 2 The process is simple and feasible, the experiment reproducibility is good, and the raw materials used are cheap and easy to obtain. figure 1 In the prepared α-MnO 2 It can be seen that the material is in a uniform linear shape with a length between 0.5 and 3 μm. A uniform structure is more conducive to th...

Embodiment 2

[0062] Preparation of positive electrode active material: 2.0g manganese sulfate (MnSO 4 ·H 2 O) Dissolve in 15ml of deionized water, 12.5g of potassium permanganate is dissolved in 20ml of water; Slowly add manganese sulfate aqueous solution to potassium permanganate aqueous solution (about 30min) with an acid burette, obtain amorphous after magnetic stirring for 1h Manganese dioxide, washed several times with deionized water and alcohol, dried for later use.

[0063] The preparation process of the positive pole piece is as follows: Grind the obtained amorphous manganese dioxide for 30-60 minutes, add binder and conductive agent in proportion, continue grinding for 30 minutes, add a certain amount of solvent, grind evenly, and obtain a slightly fluid slurry material. Coat the slurry on stainless steel foil, dry it, and punch it into discs of uniform size for later use.

[0064] Negative electrode preparation: polish the high-purity zinc sheet with 200-grit sandpaper, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com