Twin-screw extruder suitable for the production of special materials for melt-blown non-woven fabrics

A twin-screw extruder and melt-blown non-woven fabric technology, applied in the field of new polymer material production technology, can solve the problems of incomplete degradation reaction, insufficient reaction, incomplete degradation reaction, etc., and achieve full and complete reaction and molecular weight. Appropriate distribution and stable melting index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

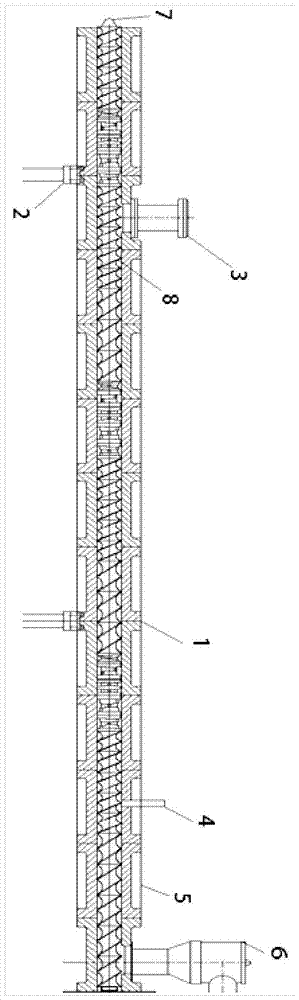

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Twin-screw extruder of the present invention, as figure 1 As shown, it includes a cylinder body 1, which is placed horizontally on the bracket 2, an exhaust chamber 3, a degradation agent injection port 4 are arranged above the cylinder body 1, and a heating tile 5 is wrapped on the surface of the cylinder body 1. One end of the cylinder body 1 The lower barrel 6 is connected, and the barrel body 1 is provided with twin-screws 7, the length-to-diameter ratio of the twin-screws 7 ranges from 40 to 58, and threaded elements 8 are sheathed on the twin-screws 7.

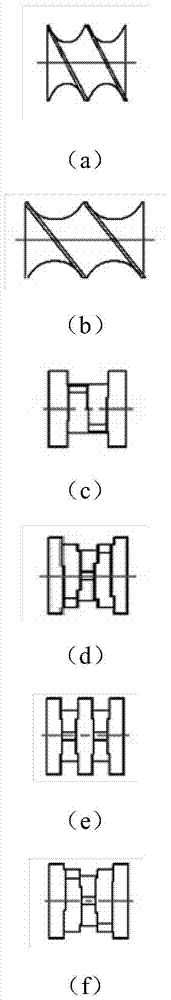

[0014] The combinations of the threaded elements 8 are: 56 / 56A, 96 / 96, 72 / 72, 56 / 56, 56 / 56, 56 / 56, 56 / 56, 56 / 56, 56 / 56, 45° / 5 / 96, 56 / 56, 72 / 72, 56 / 56, 45° / 5 / 56, 60° / 4 / 56, 45° / 5 / 56, 56 / 56, 56 / 56, 45° / 5 / 56 , 45° / 5 / 56, 45° / 5 / 56, 56 / 56, 45° / 5 / 56, 60° / 4 / 56, 90° / 5 / 56, 56 / 56, 45° / 5 / 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com