Patents

Literature

78 results about "Bisphenol Z" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical Lens

ActiveUS20100048855A1Reduce light transmittanceHigh glass transition temperatureSynthetic resin layered productsMountingsCamera lensPolymer science

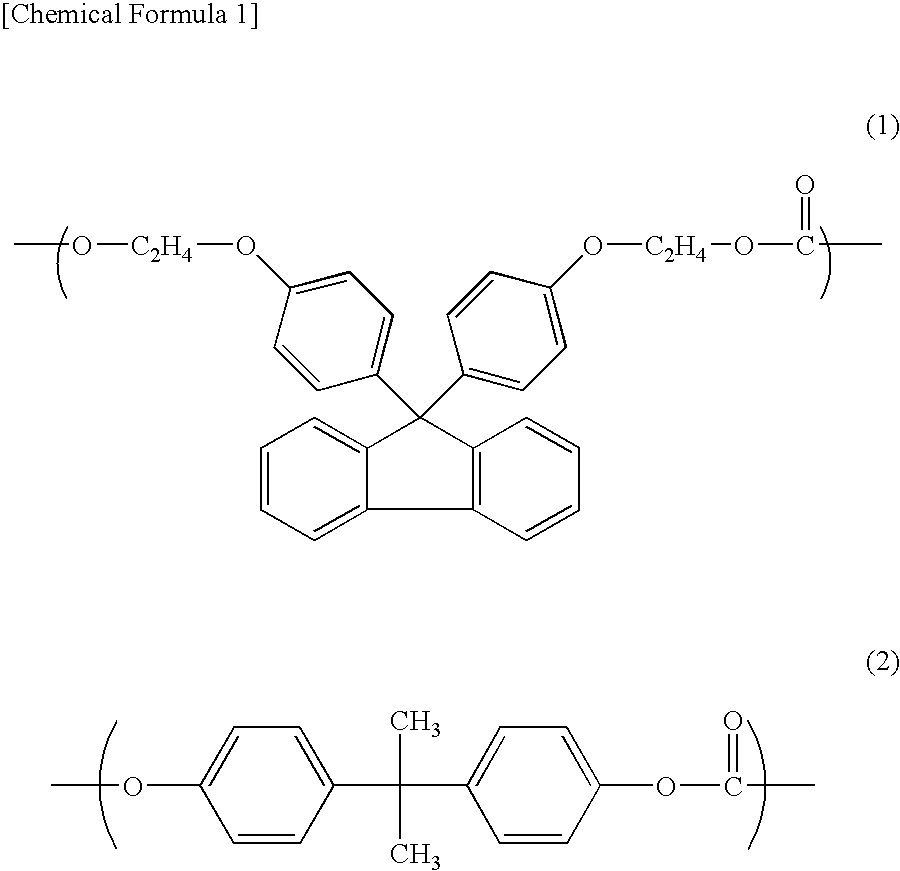

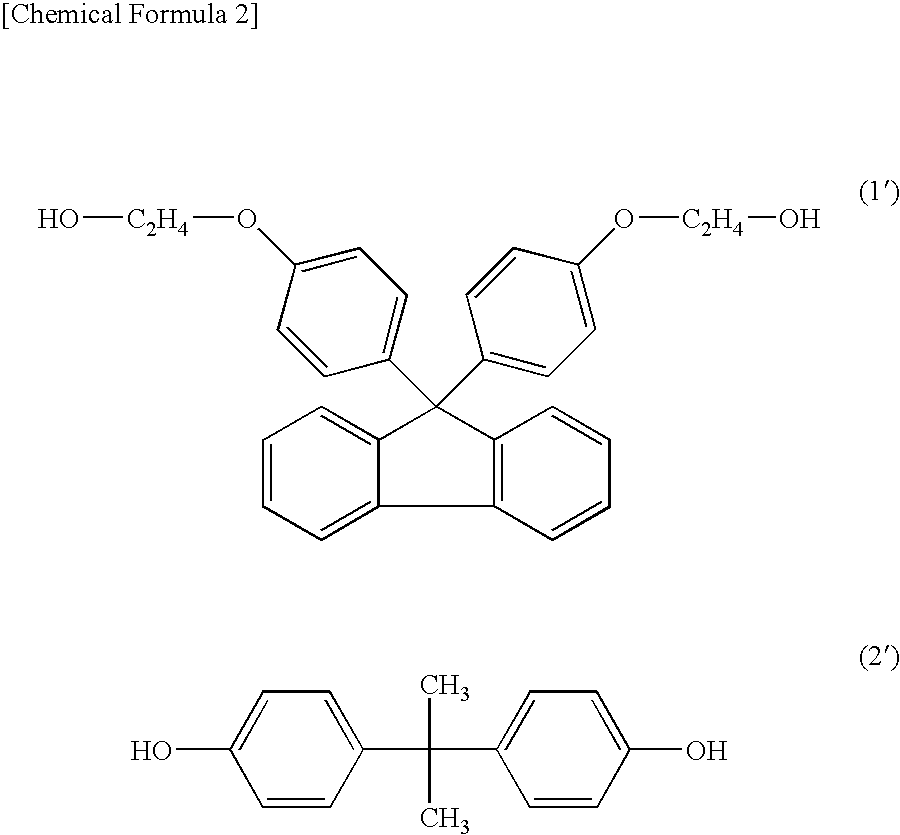

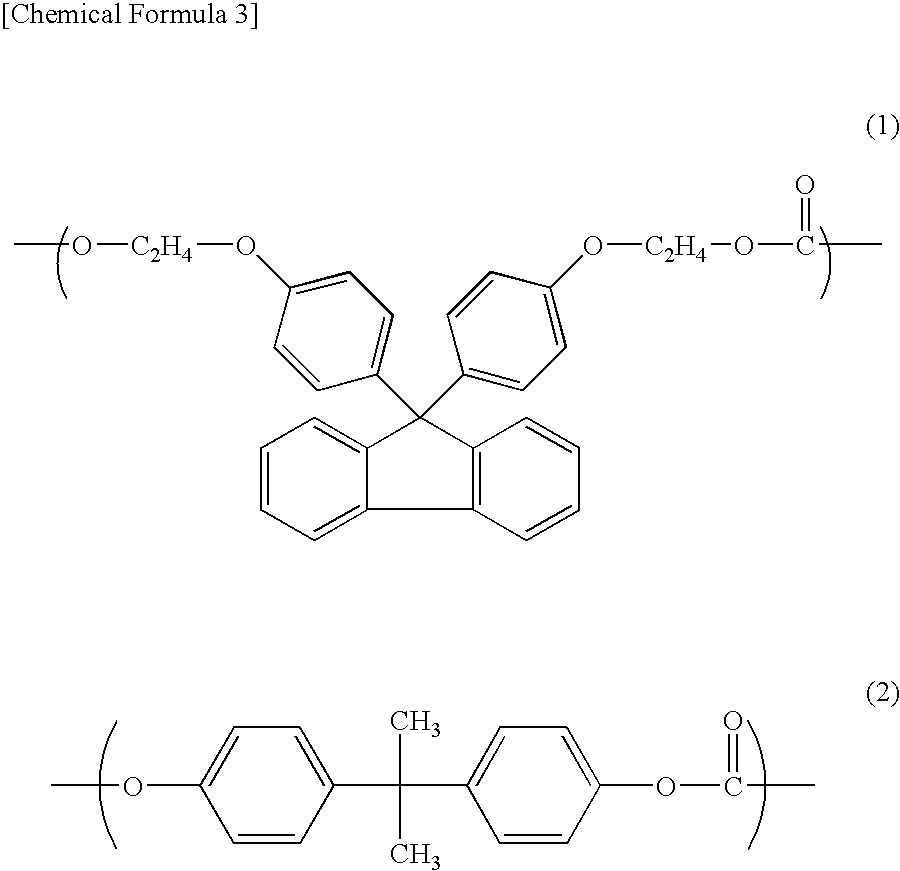

Disclosed is an optical lens which can be produced by injection molding on an industrial scale and which has a high refractive index, a low Abbe's number, a low birefringence index, a high transparency and a high glass transition temperature. The optical lens can be produced by injection molding of a polycarbonate resin (preferably having a reduced viscosity of 0.2 dl / g or higher and a glass transition temperature of 120 to 160° C.), wherein the polycarbonate resin is produced by reacting a diol component comprising 99 to 51 mol % of 9,9-bis(4-(2-hydroxyethoxy)phenyl)fluorene and 1 to 49 mol % of bisphenol A with a carbonate diester. It becomes possible to produce an optical lens preferably having a refractive index of 1.60 to 1.65, an Abbe's number of 30 or smaller, a birefringence index of 300 nm or lower and an all light transmittance of 85.0% or higher.

Owner:MITSUBISHI GAS CHEM CO INC

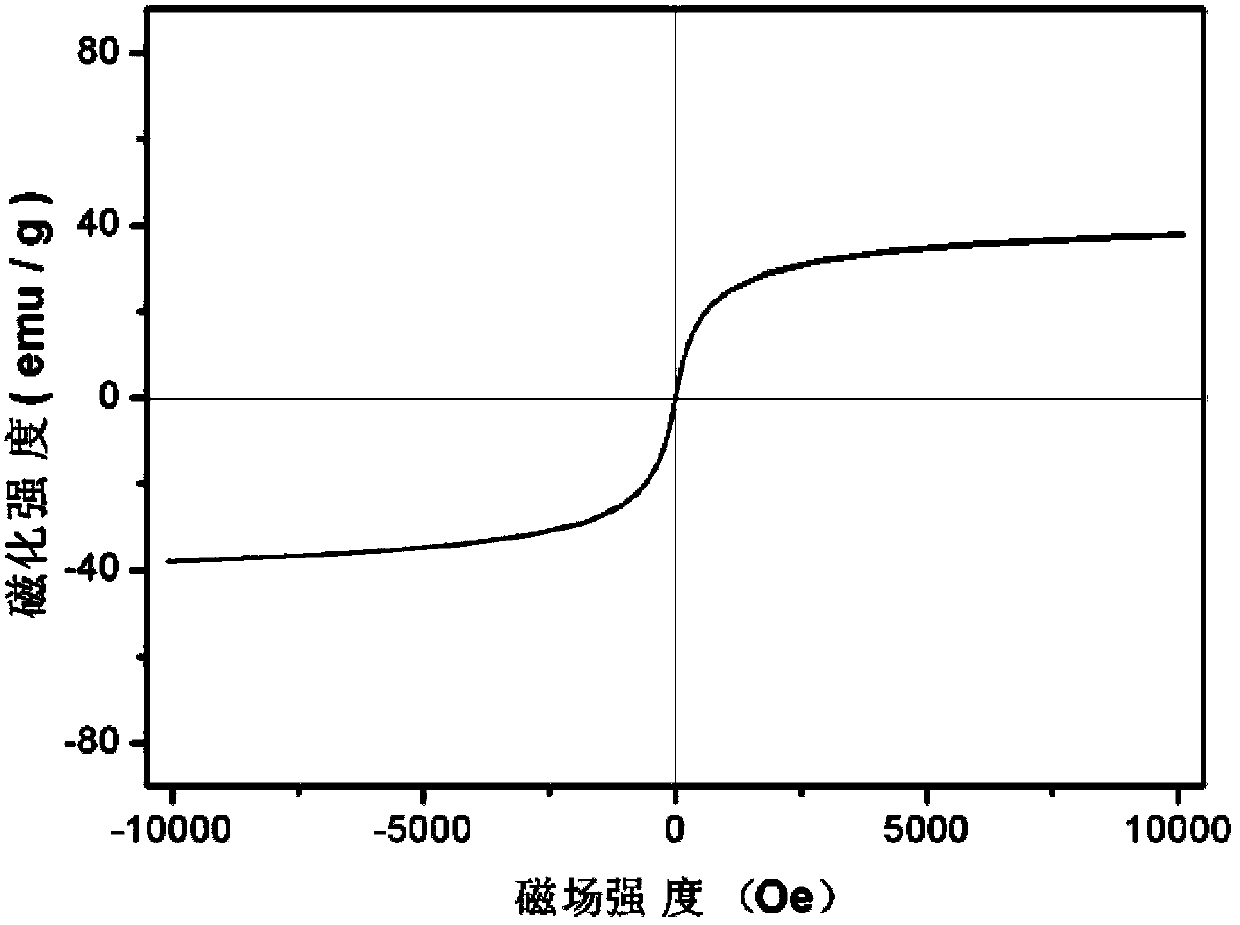

Reduction-oxidation graphene-Fe3O4 nano composite, preparation method thereof, and application of reduction-oxidation graphene-Fe3O4 nano composite in absorbing bisphenol A

InactiveCN103418340AImprove adsorption capacityEasy to separateOther chemical processesWater contaminantsBisphenol AGraphite oxide

The invention discloses a reduction-oxidation graphene-Fe3O4 nano composite, a preparation method thereof, and an application of the reduction-oxidation graphene-Fe3O4 nano composite in absorbing bisphenol A. The reduction-oxidation graphene-Fe3O4 nano composite comprises Fe3O4 nano particles and reduction-oxidation graphene. The reduction-oxidation graphene-Fe3O4 nano composite and a solution containing the bisphenol A are in full contact in an ambient temperature, the bisphenol A is absorbed and removed. Compared with the prior art, the advantages of small material dose, simplicity in operation, mild processing condition, fast processing speed, and no harm for the environment, and recycling nano-composite materials, and the like are achieved.

Owner:上海出入境检验检疫局工业品与原材料检测技术中心 +1

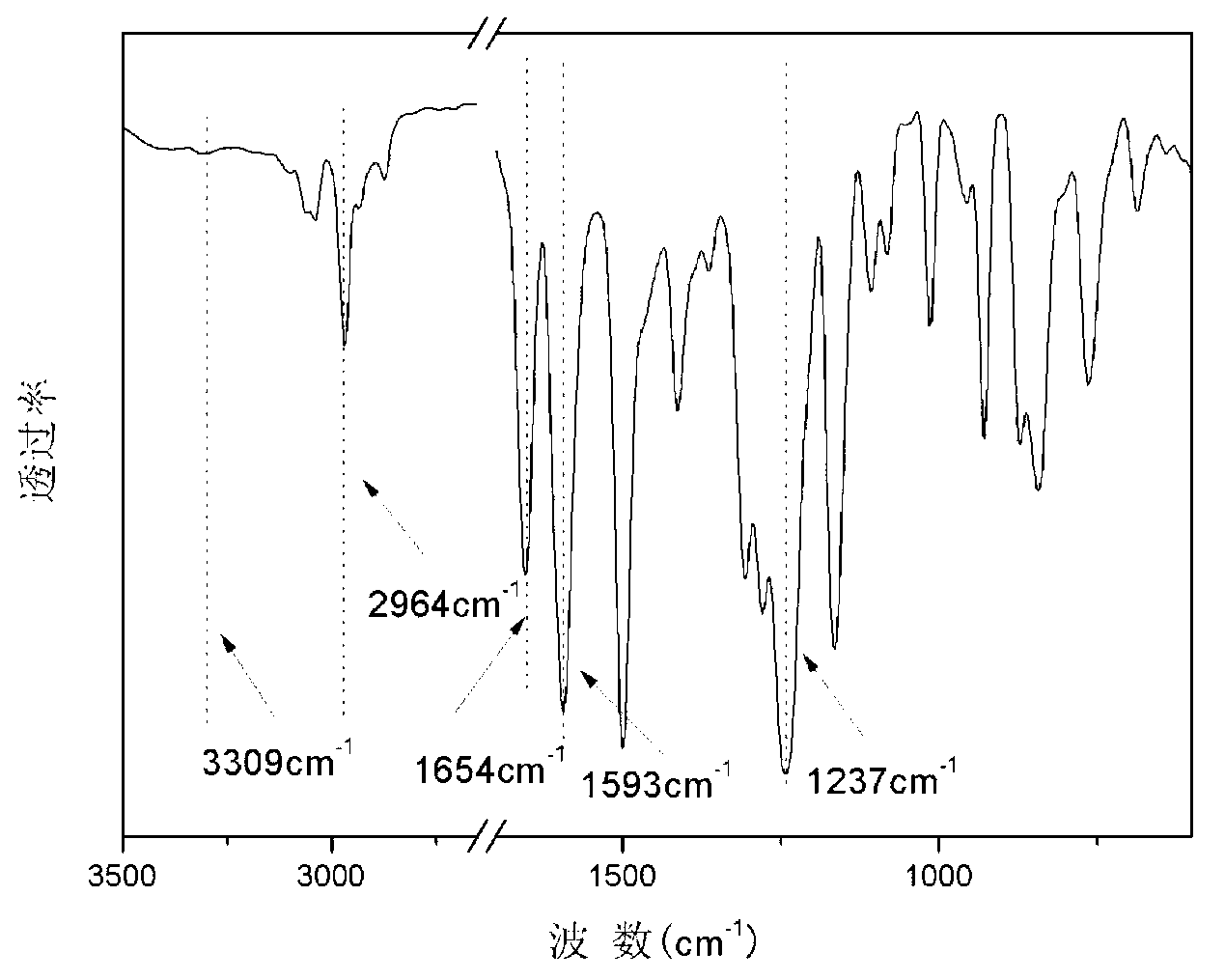

Preparation method of light-resistant water-based polyurethane coating

InactiveCN103436155AGood compatibilityGood light fastnessPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method of a light-resistant water-based polyurethane coating. The preparation method comprises the following steps of: mixing bisphenol S and diisocyanate in the presence of a dibutyltin dilaurate catalyst, and stirring to react at 60-85 DEG C for 1.5-3.5 hours to obtain a polyurethane prepolymer A; adding a hydrophilic chain extender with carboxyl content accounting for 1.2%-4.6% of the weight of A into A, then adding a solvent which accounts for 15%-35% of the weight of A, and stirring to react under the condition of 80-95 DEG C for 1.0-4.0 hours; adding triethylamine according to the condition that the mole ratio of COOH / NH2 is 0.6:(1-1.6):1 for neutralization, stirring to react for 30-70 minutes, and adding water for emulsification to form the light-resistant water-based polyurethane coating. The prepared light-resistant water-based polyurethane is environmentally-friendly and low in cost and can meet the requirement of the market on the property of light-resistant polyurethane.

Owner:HESHAN YIXIN CHEM CO LTD

Moisture-curable polyurethane hot melt adhesive, and laminate and moisture-permeable film using the same

ActiveUS20100104831A1Good moisture permeabilityHigh mechanical strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterMilitary Uniforms

A moisture-curable polyurethane hot-melt adhesive containing a urethane prepolymer obtained by reacting a polyol (A) which comprises a polyester polyol (a-1) obtained by reacting a polyol prepared by the addition of bisphenol A with an alkylene oxide with both an aliphatic polycarboxylic acid and an aromatic polycarboxylic acid, a crystalline polyester polyol (a-2), and a polyoxyethylene glycol (a-3) having a number-average molecular weight of 2000 to 25000 with a polyisocyanate (B); and a moisture-permeable film, which are suitable for the production of sport wear, raincoats, shoes, fireman uniforms, military uniforms, and so on.

Owner:DAINIPPON INK & CHEM INC

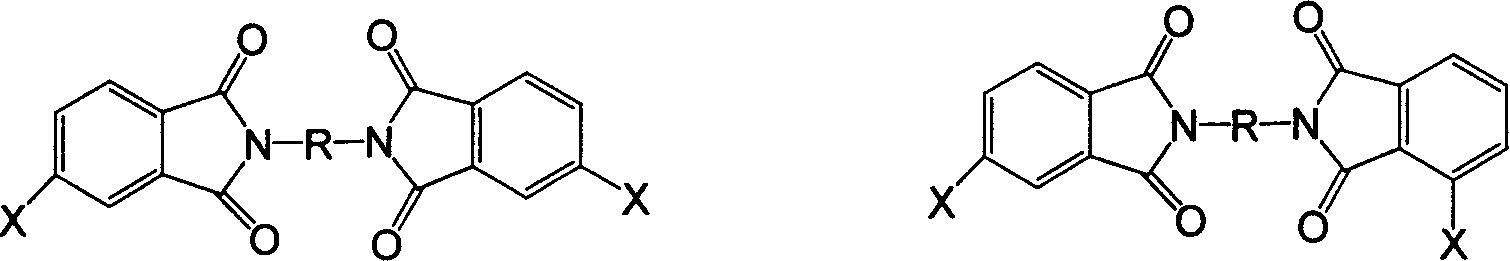

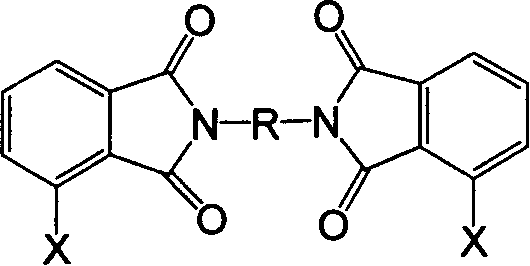

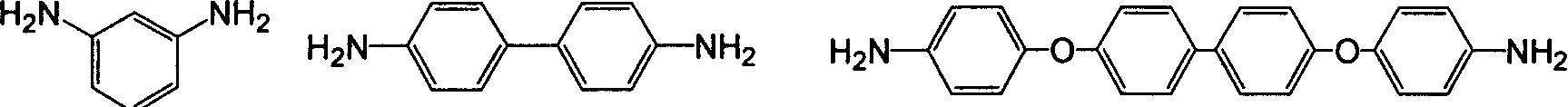

Method for preparing polyether imide copolymer by bisubstituted compound and bisphenol

The disclosed polyetherimide copolymer is copolymerized in dichloro-benzenes with the material with disubstituted phthalimide, diamine as NH2-R-NH2 and proper NH2-R-NH2 and 4, 4-dichlorodiphenyl sulfone. This invention reduces cost, simplifies process, and can recover the solvent conveniently.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

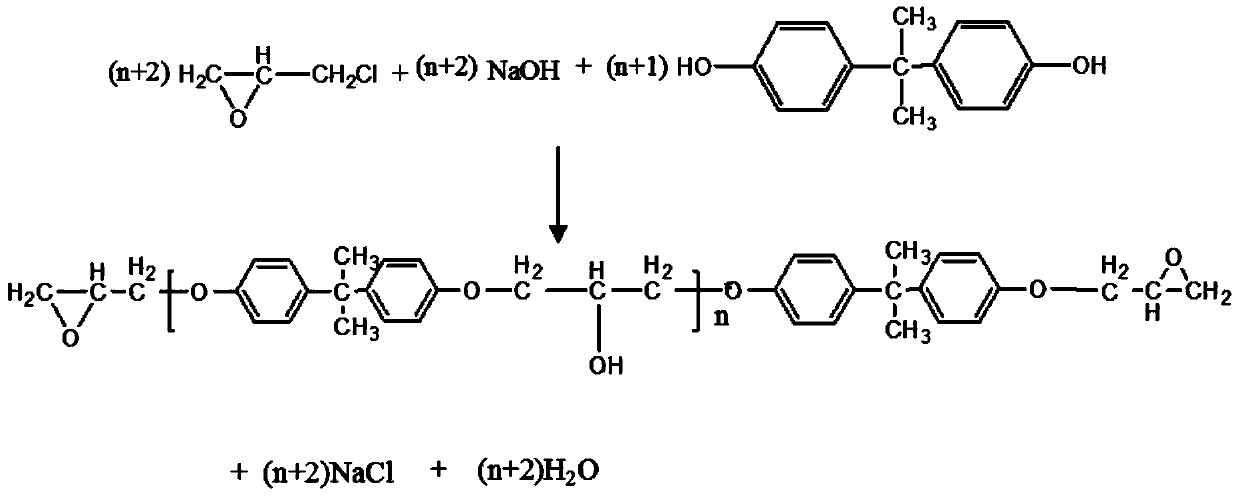

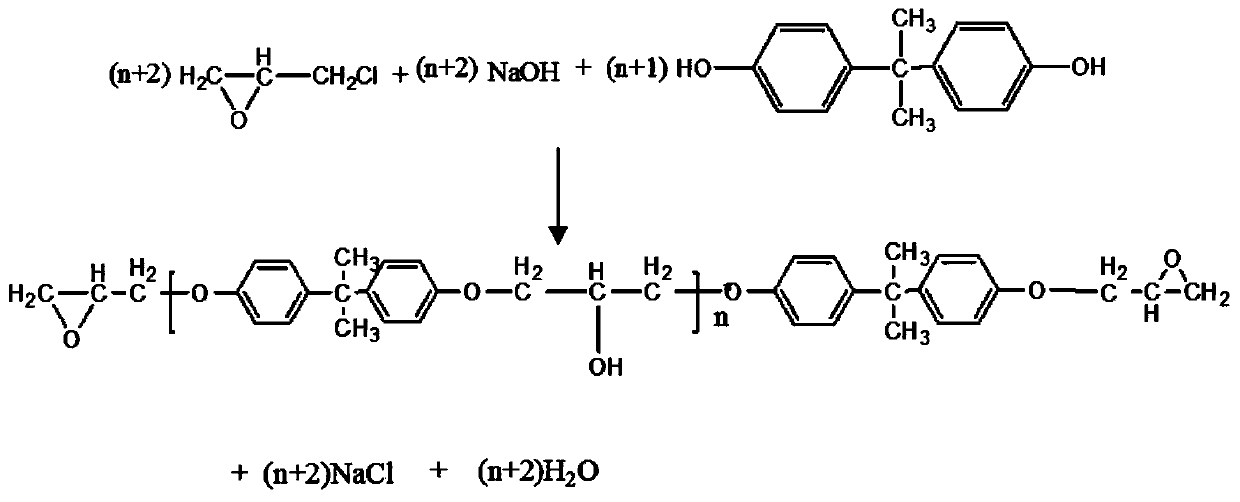

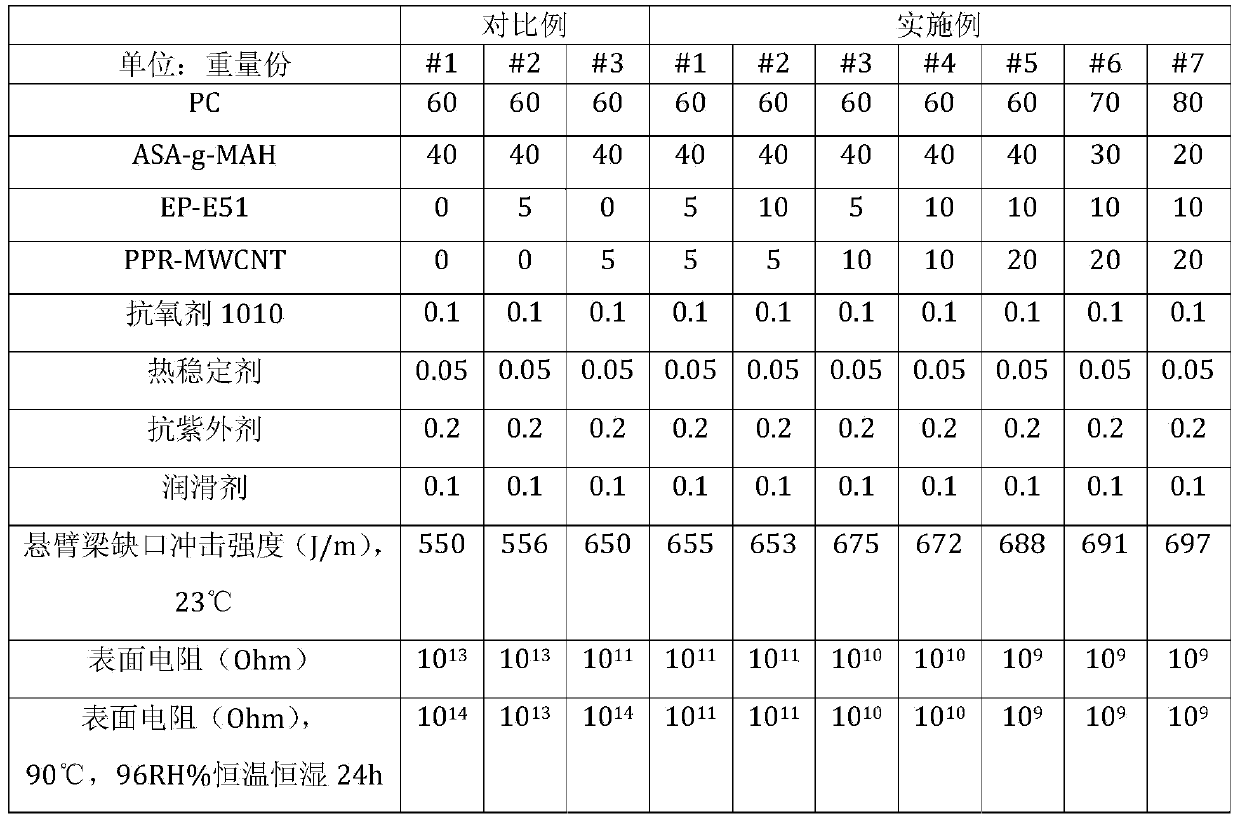

Anti-hydrolysis anti-static PC/ASA alloy and preparation method thereof

The invention provides anti-hydrolysis anti-static PC / ASA alloy and a preparation method thereof. According to the method, condensation polymerization is conducted on PPR-MWCNT compounds and ASA-g-MAH grafted copolymer through bisphenol A and epoxy chloropropane, bisphenol A epoxy resin (EP-E51) and polycarbonate (PC) are obtained and are subjected to blending extrusion, and the anti-hydrolysis anti-static PC / ASA alloy is obtained. The prepared anti-hydrolysis anti-static PC / ASA alloy has excellent anti-static performance and excellent hydrolysis resistance, is suitable for the moist rainwater weather, has excellent impact toughness and lower processing viscosity, is easy to process and suitable for mass production and popularization, and can be oriented to automobile inside and outside ornaments such as an automobile rearview mirror shell body and an automobile door plank and outdoor sport equipment.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

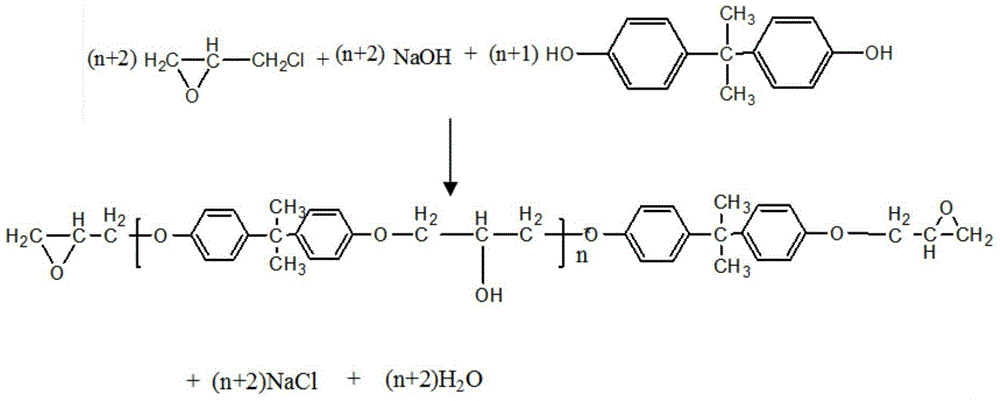

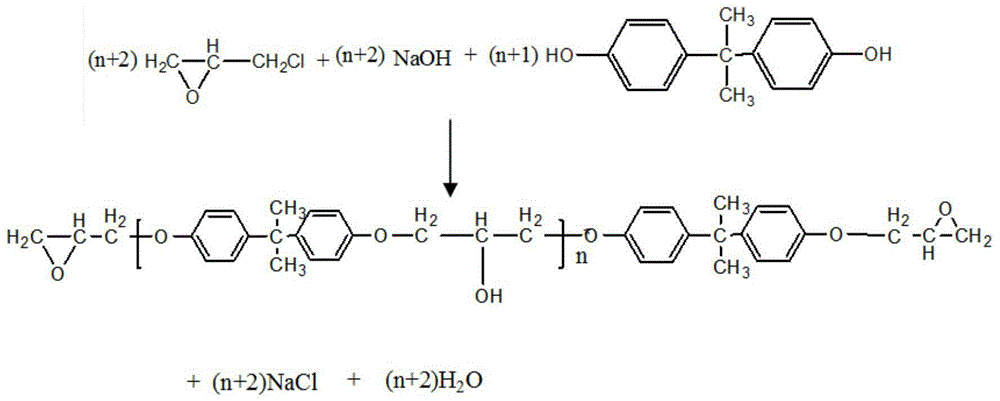

Epoxy resin nanometer montmorillonite composite material and preparation method thereof

InactiveCN102229700AImprove performanceImprove toughnessPowdery paintsEpoxy resin coatingsHeat resistanceMontmorillonite

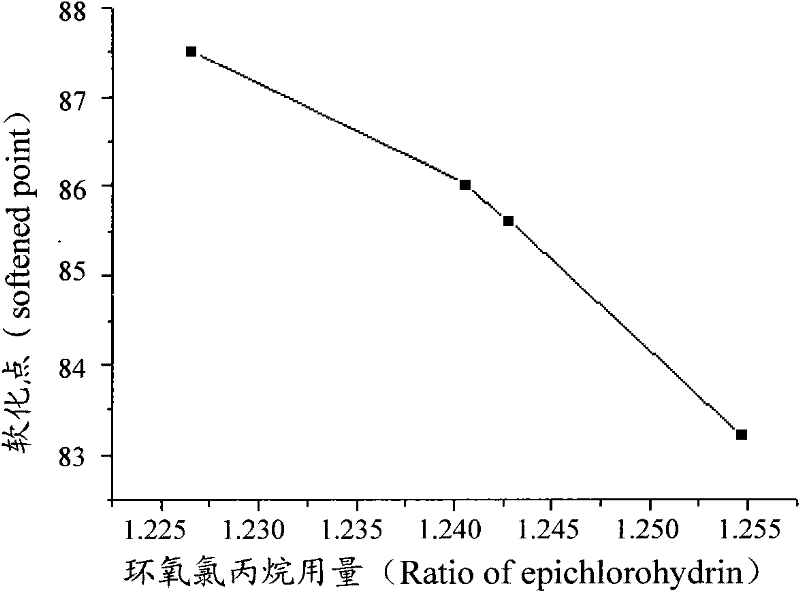

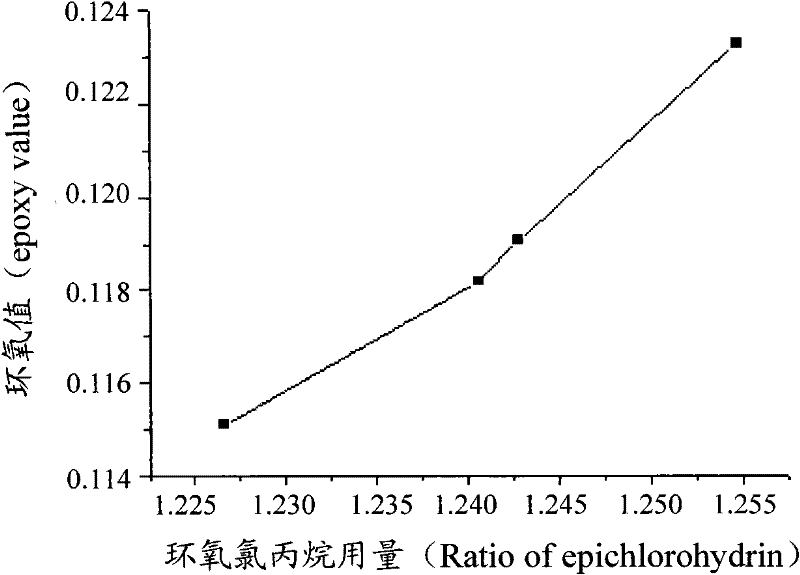

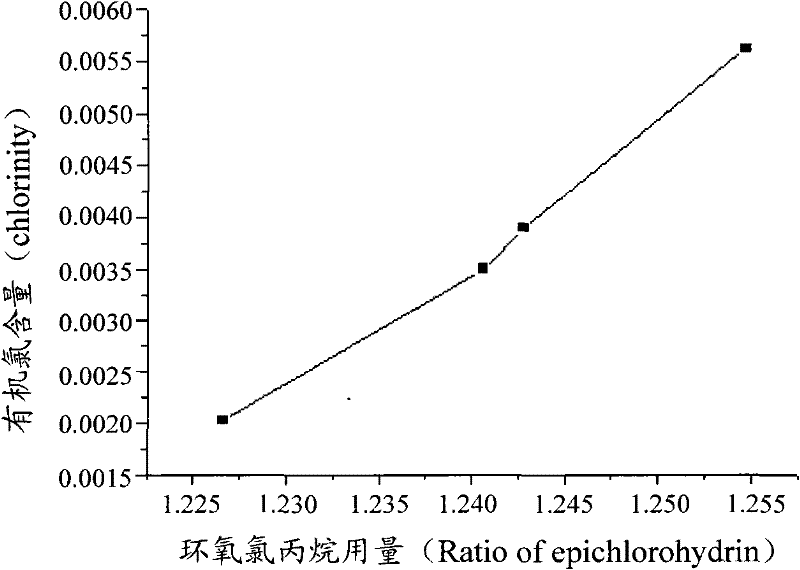

The invention discloses an epoxy resin nanometer montmorillonite composite material and a preparation method thereof. The method comprises the steps of acidizing of montmorillonite, organizing of montmorillonite and synthesizing of the composite material. The components and corresponding content of each component of the epoxy resin nanometer montmorillonite composite material are as follows: the mass ratio of epoxy resin to montmorillonite is in a range of 97:3 to 95:5, the mol ratio of bisphenol A to chloropropylene oxide is in a range of 1:1.2 to 1:1.3, and the mol ratio of bisphenol A to sodium hydroxide is in a range of 1:1.1 to 1:1.3. The epoxy resin nanometer montmorillonite composite material prepared in the invention has excellent overall properties; toughness, impact strength and hear resistance the material are superior to those of universal type epoxy resins; production cost of the material is low; the material meets application requirements for epoxy powdery paints; and the invention has good performance and economic advantages.

Owner:ANHUI SHANFU NEW MATERIAL TECH

Preparation method of heat-resisting modified polyurethane composite

The invention discloses a preparation method of heat-resisting modified polyurethane composite, comprising: adding hexafluobisphenol A and 3-aminopropyl-methyldimethoxysilane into a reaction container, and reacting to obtain silicon-bearing chain extender; mixing well polycarbonate diols, hydroxyl-terminated liquid silicon rubber, nano calcium carbonate, montmorillonite and epoxy resin, adding 1,4-cyclohexane diisocyanate, dibutyltin dioctanoate and butanone, and stirring and reacting to obtain polyurethane prepolymer; mixing well the polyurethane prepolymer with 1,4-bis(2-hydroxyethoxy)benzene, 4,4'-diaminodiphenyl and the silicon-bearing chain extender, and stirring and reacting and then curing to obtain the heat-resisting modified polyurethane composite. The preparation method of the heat-resisting modified polyurethane composite provided herein has a simple process and mild conditions, and the obtained composite has high strength, good heat resistance and excellent ageing resistance and can meet the requirement of use in various fields.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

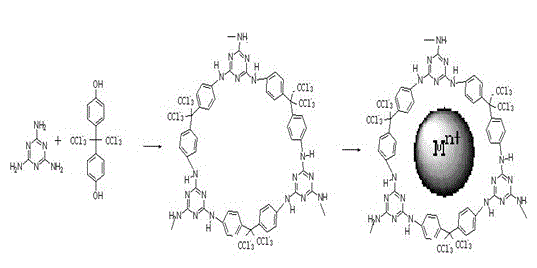

Preparation method of amino group-containing porous material, and application of amino group-containing porous material in recover of waste electric appliance precious metals

InactiveCN104910379AReduce pollutionReduce recycling costsProcess efficiency improvementGreen environmentMelamine

The invention provides a preparation method of an amino group-containing porous material, and an application of the amino group-containing porous material, and relates to the field of materials. The preparation method of the amino group-containing porous material is characterized in that the amino group-containing porous material is obtained through copolymerizing 4,4'-(hexachloroisopropylidene)bisphenol and melamine in an alkaline solution. The amino group-containing porous material can adsorb precious metal ions to make a waste metal treatment fluid repeatedly used, so the process flow is simplified, the precious metal recovery cost is reduced, changing of wastes into valuables is realized, pollution discharge is reduced, and environmental protection and green environment requirements are met. The material can be expected to be massively applied in the future industrial production.

Owner:周卫星

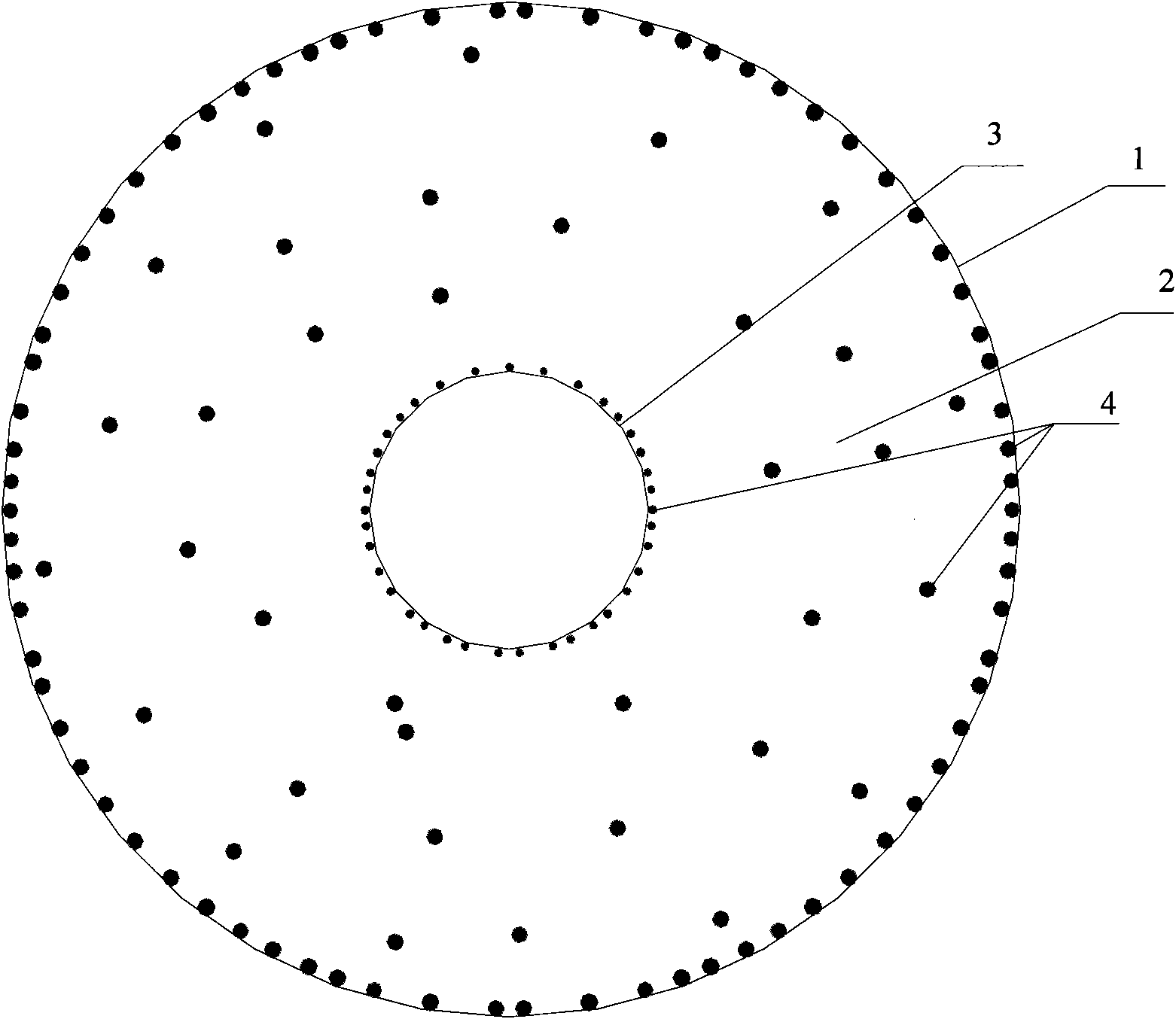

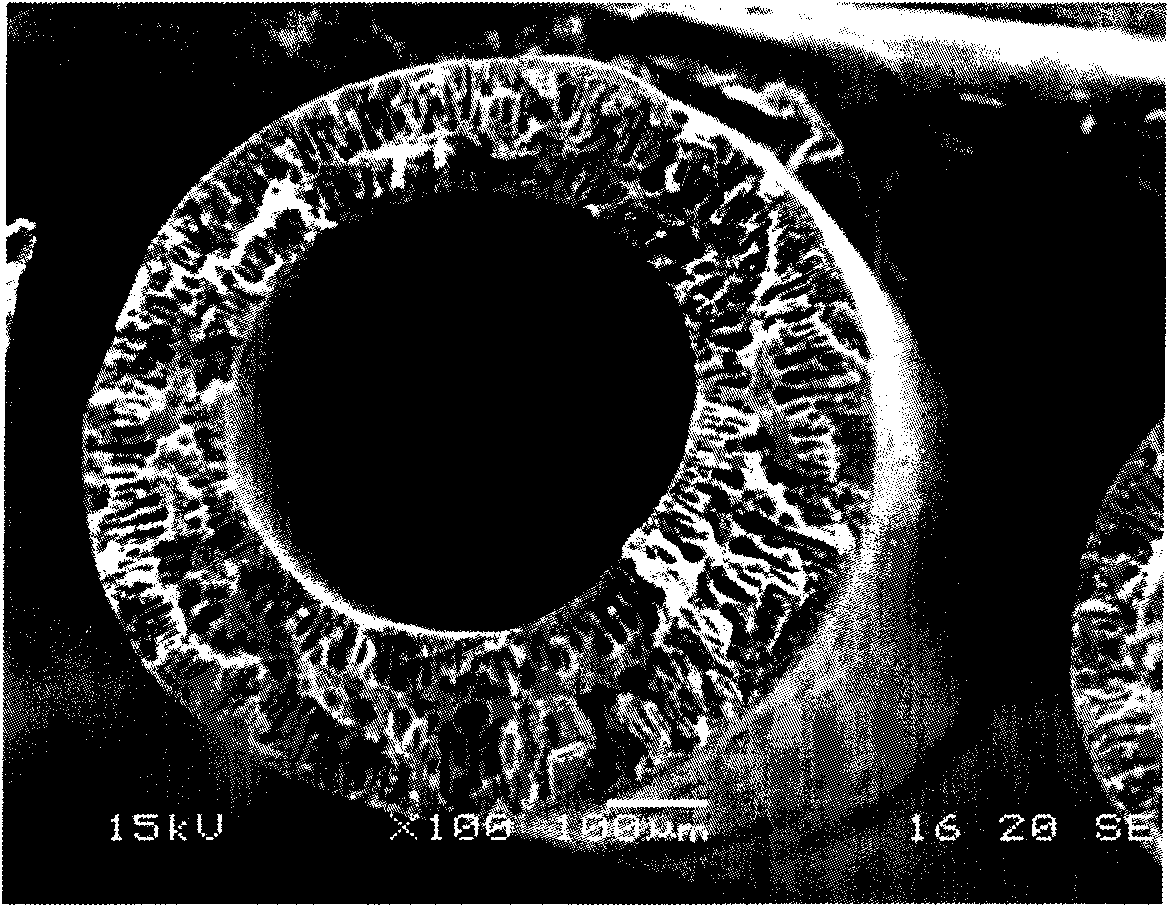

Activated carbon hollow fiber polysulfone membrane and preparation method thereof

InactiveCN101596420ASimple structureReduce direct impactSemi-permeable membranesFiberActivated carbon

The invention discloses an activated carbon hollow fiber polysulfone membrane and a preparation method thereof; the membrane is an asymmetrical three-layer structure which comprises an outer surface layer, a middle support layer and an inner surface layer from outside to inside; the three layers are evenly distributed with activated carbon particles with particle sizes being less than or equal to 10mu m, specific surface area being 1104m / g, void volume being 0.92cm / g; continuous phase of the membrane is transparent bisphenol A polysulfone which is obtained by polycondensation of bisphenol A and 4, 4-dichloro diphenylsulfone and provided with molecular weight ranging from 100000 to 116500. The preparation method has the following steps: mixing the polysulfone, the activated carbon particles and 1-methyl-2 pyrollidone according to the mass ratio of 1:4:5-1:5:5; heating to melt the mixture and then obtaining the activated carbon hollow fiber polysulfone membrane by adopting wet-type spinning process with wet spinning distance being 2m, spinning extrusion volume flow rate being 12-15mL / min and spinning solution temperature being 75-80 DEG C. The activated carbon particles are made of coconut shells, the average grain diameter is less than 10mu m, the specific surface area is 1104m / g, and the void volume is 0.92cm / g. The membrane treatment effect is fine, the treatment time is short and the adsorbability of the membrane is high.

Owner:HOHAI UNIV

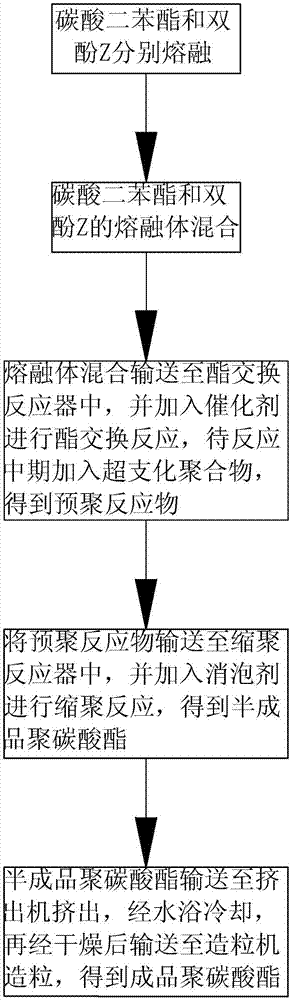

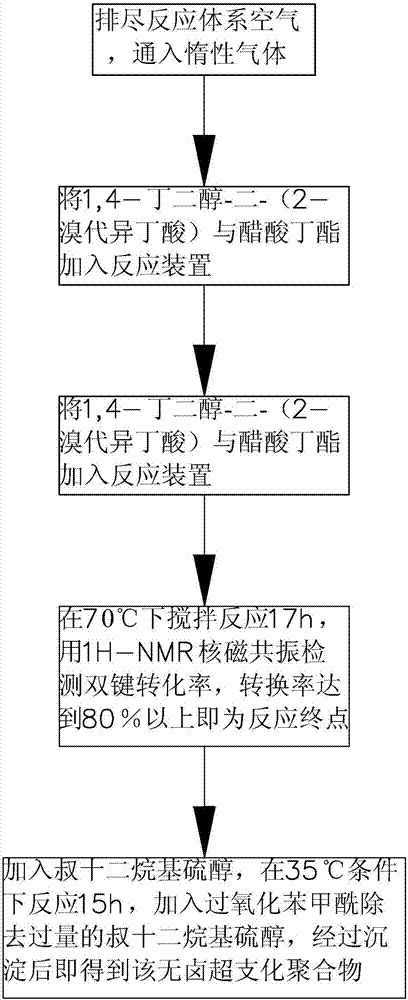

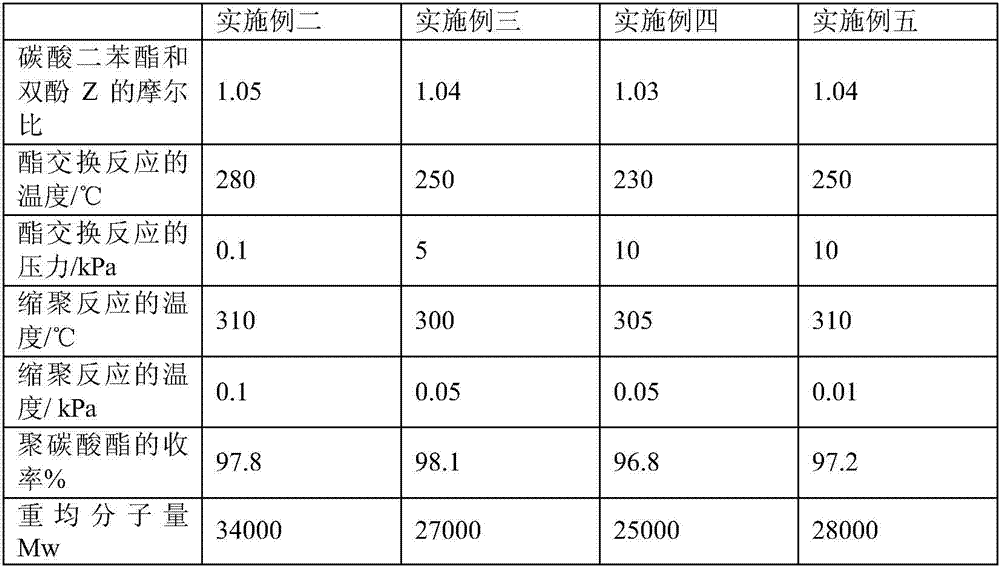

Preparation process of polycarbonate

Owner:NINGBO ZHETIE DAPHOON CHEM

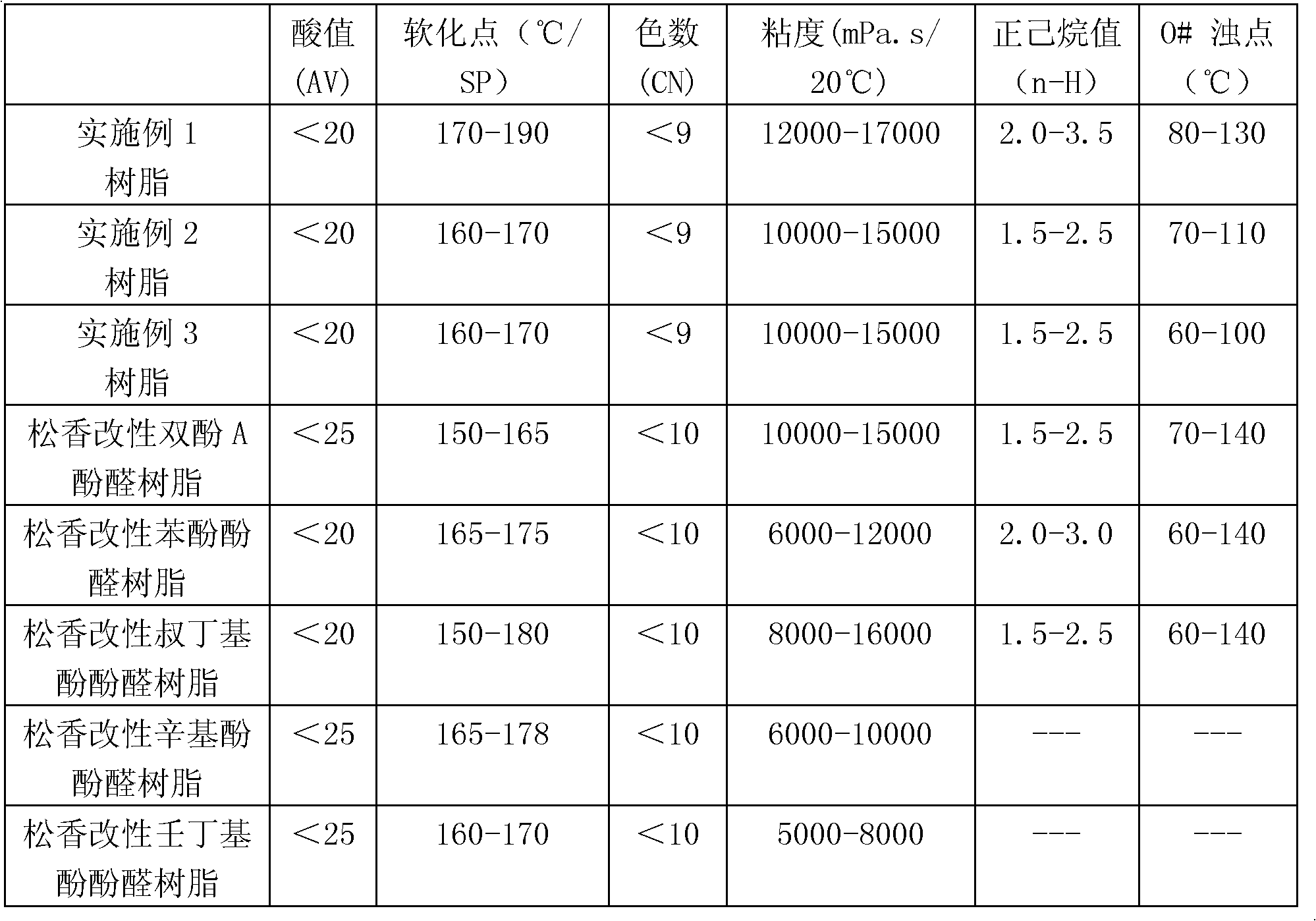

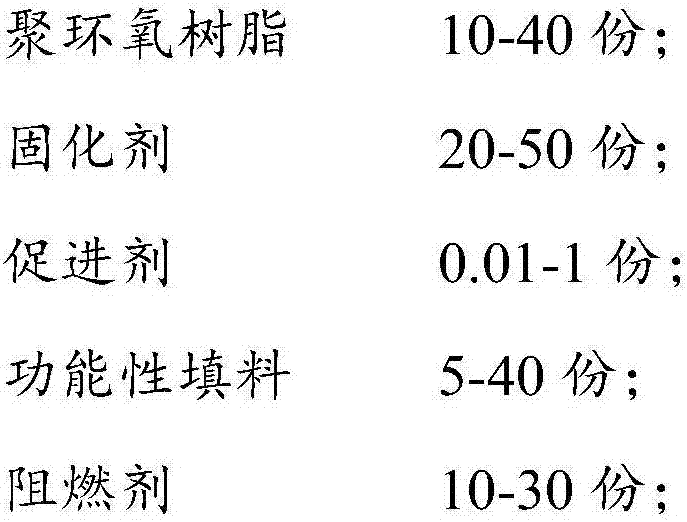

Resin composition and application thereof

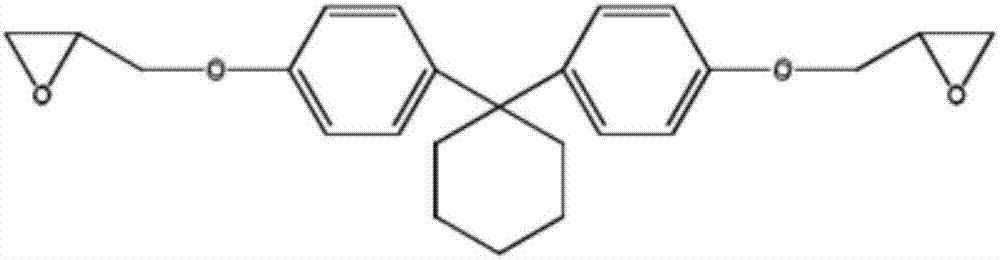

The invention relates to a resin composition. The resin composition comprises, by weight, 10 to 40 parts of polyepoxy resin, 20 to 50 parts of a curing agent, 0.01 to 1 part of an accelerant, 5 to 40 parts of a functional filling material and 10 to 30 parts of a fire retardant, wherein the polyepoxy resin comprises at least one selected from a group consisting of bisphenol Z type epoxy resin and t-butyl modified phenol phenolic epoxy resin, and / or one or more selected from a group consisting of cyclopentadiene epoxy resin, bisphenol A type epoxy resin, bisphenol F type epoxy resin and bisphenol M type epoxy resin. A copper-clad plate prepared from the resin composition has a low dielectric constant (wherein Dk is no more 3.4), low dielectric loss (wherein Df is no more 0.01) and a high glass-transition temperature under the conditions of 1 GHz and RC70. The copper-clad plate can be applied to substrate-like systems to meet requirements of the systems for low dielectric constants of plates.

Owner:无锡宏仁电子材料科技有限公司

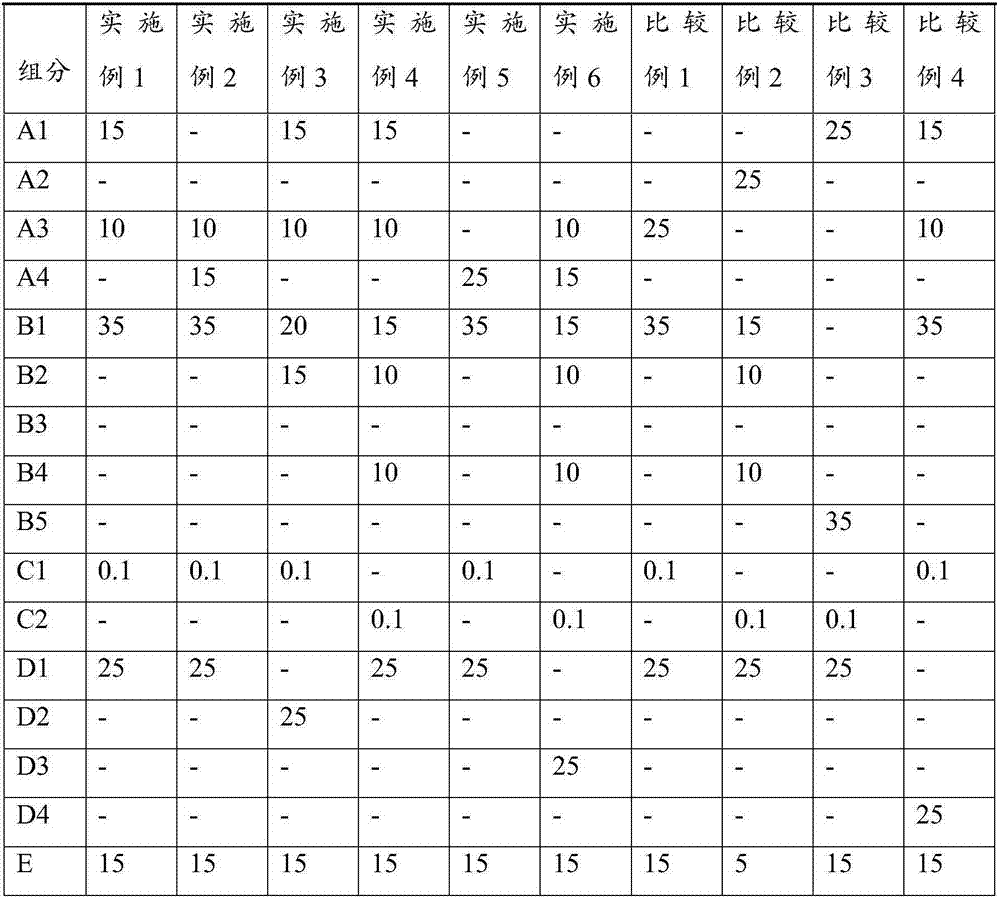

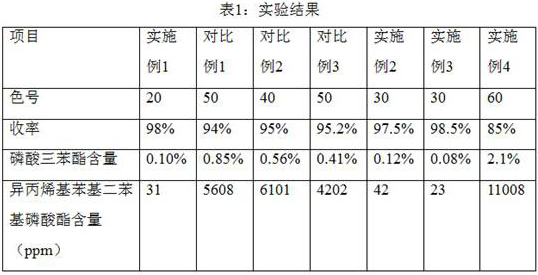

Continuous industrial production method of high-purity bisphenol A-bis (diphenyl phosphate)

ActiveCN112409404AHarmfulImprove responseGroup 5/15 element organic compoundsPhosphoric Acid EstersPtru catalyst

The invention discloses a continuous industrial production method of high-purity bisphenol A bis (diphenyl phosphate). The method comprises the following steps: dividing bisphenol A into two parts, mixing part of bisphenol A with phosphorus oxychloride and a Lewis acid catalyst, adding the mixture into a continuous multistage crosslinking reactor, reacting, and evaporating to remove excessive phosphorus oxychloride after the reaction is ended, adding an organic alkali acid-binding agent into the distillation residual liquid to react with the residual bisphenol A for 1.5-3 hours at the temperature of 115-120 DEG C to obtain an intermediate product reaction liquid, mixing the intermediate product reaction liquid with phenol, feeding the mixture into a multi-stage esterification reactor for esterification reaction, continuously supplying consumed phenol in the esterification process, and obtaining a crude product after the reaction is finished; and sequentially carrying out continuous acid washing, continuous alkali washing, continuous water washing, continuous solvent recovery and filtration to obtain the bisphenol A-bis (diphenyl phosphate) finished product. According to the method,the production cost is reduced, the product yield is increased to 97% or above, the product color number is increased to 50 or below, TPP is controlled to be 0.1%, isopropenyl phenyl diphenyl phosphate is smaller than 50 ppm, and fluctuation of quality indexes of all products is small.

Owner:ZHEJIANG WANSHENG

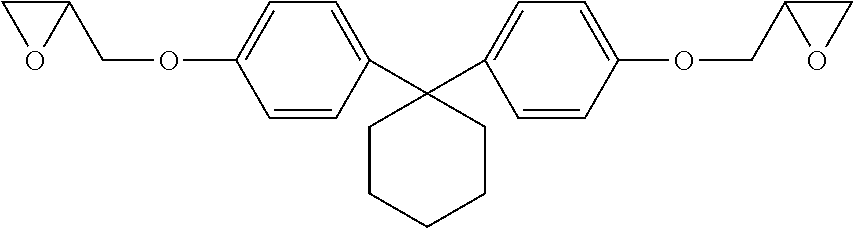

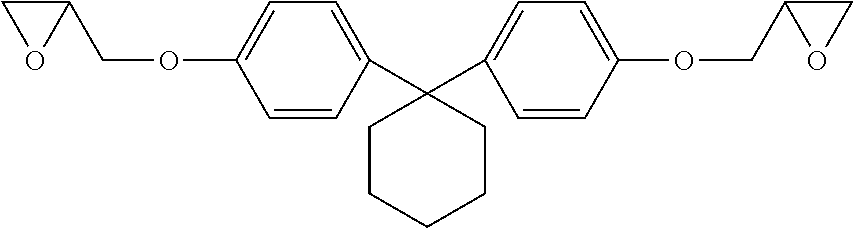

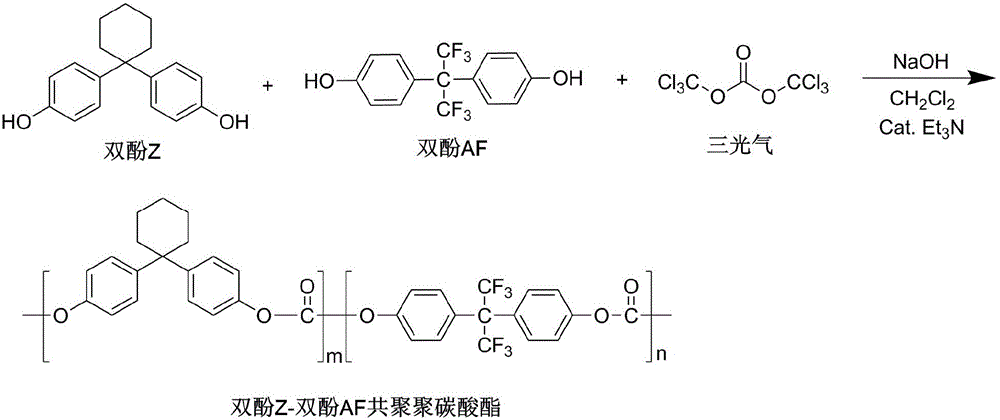

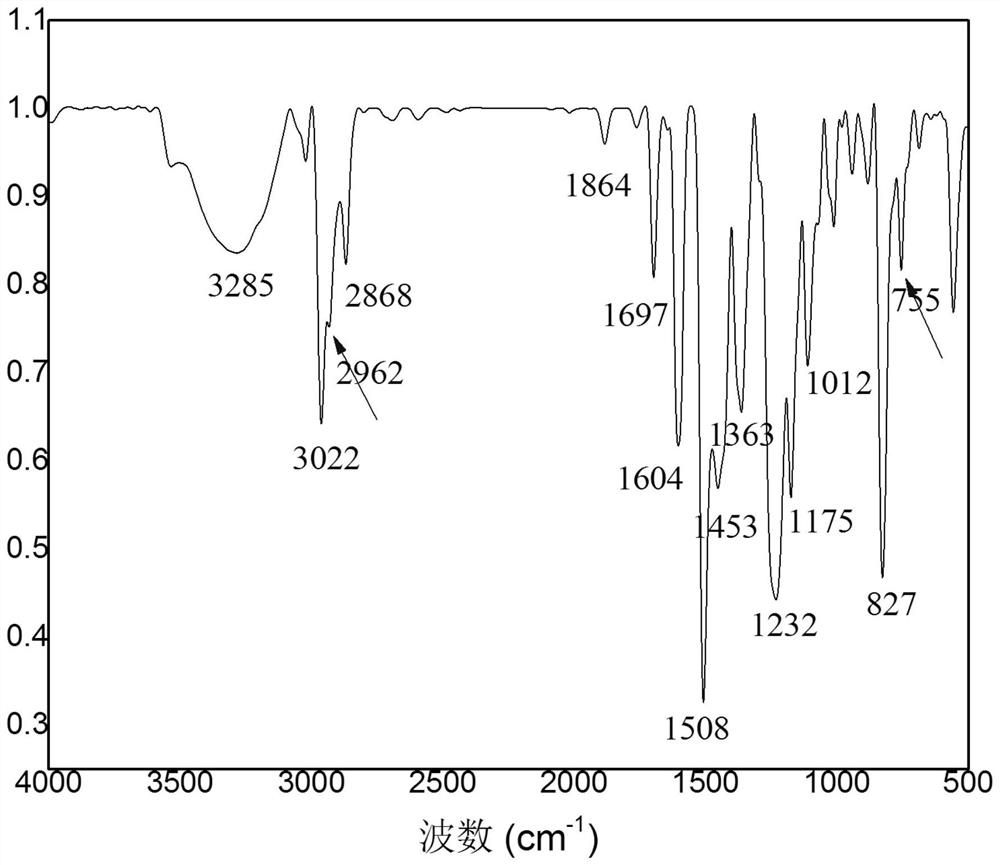

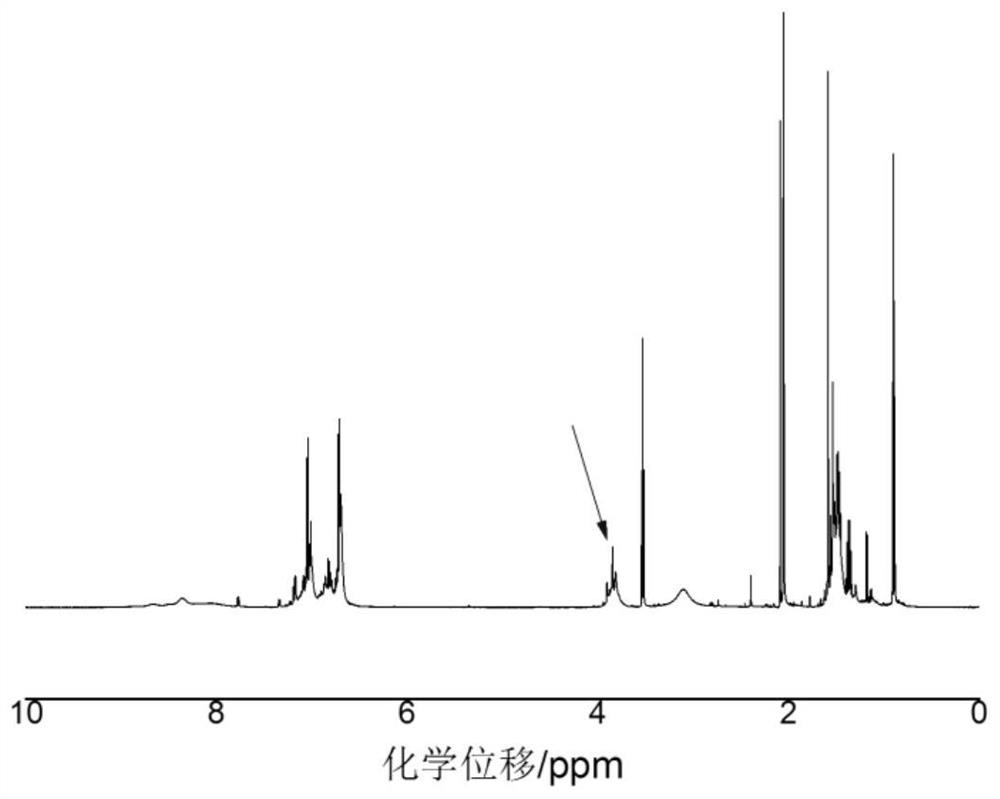

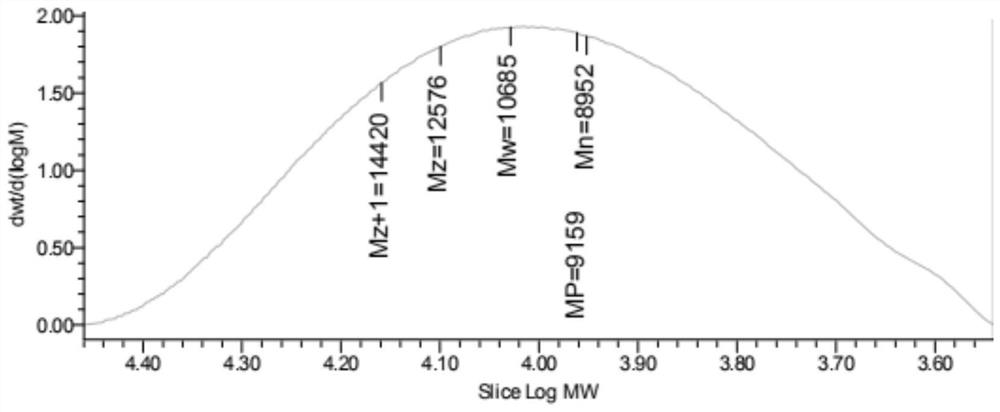

Bisphenol Z-bisphenol AF copolymer polycarbonate adhesive resin as well as preparation method thereof and application

ActiveCN105860048AImprove solubilityModerate molecular weight distributionElectrography/magnetographyAdhesivesSolubilityPolymer science

The invention relates to bisphenol Z-bisphenol AF copolymer polycarbonate adhesive resin as well as a preparation method and application thereof. Bisphenol Z and bisphenol AF are copolymerized in a certain proportion to prepare binary copolymer polycarbonate; and according to needs of different solubility, the bisphenol Z, the bisphenol AF and triphosgene in different proportions are copolymerized to prepare the bisphenol Z-bisphenol AF copolymer polycarbonate. According to the bisphenol Z-bisphenol AF copolymer polycarbonate, the binary copolymer polycarbonate prepared by copolymerizing the bisphenol Z, the bisphenol AF and the triphosgene is proper in molecular weight distribution, is relatively good in solubility, and is relatively low in cost; and the binary copolymer polycarbonate is used as adhesive resin of a carrier transmission material for preparing a carrier transmission layer of an organic optical conductor.

Owner:JIANGSU UNIV OF TECH

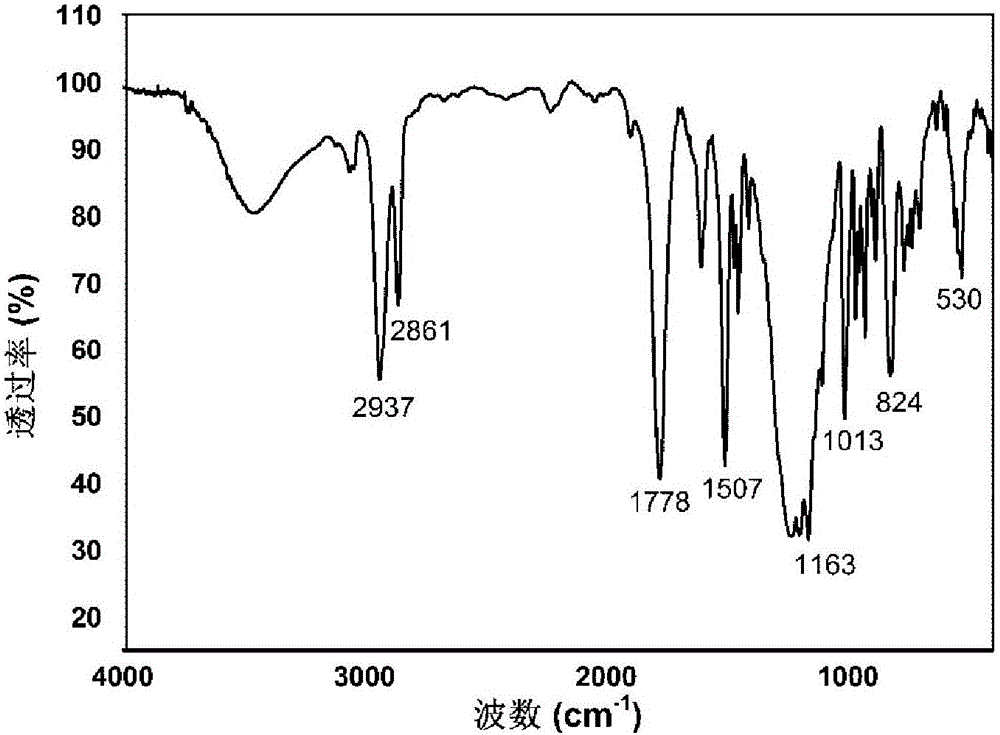

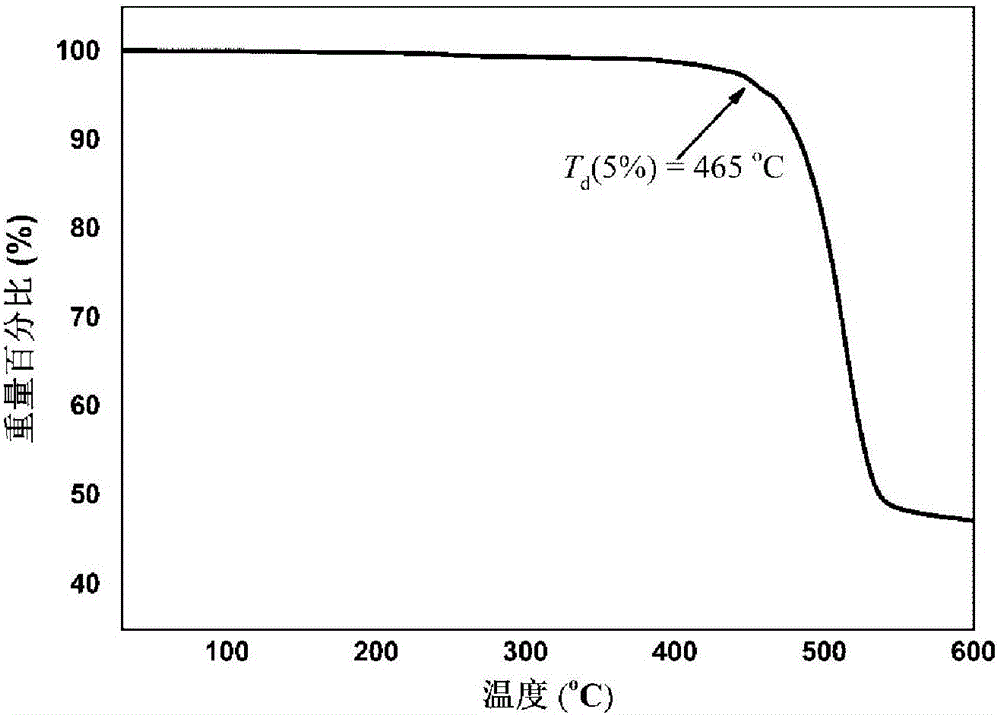

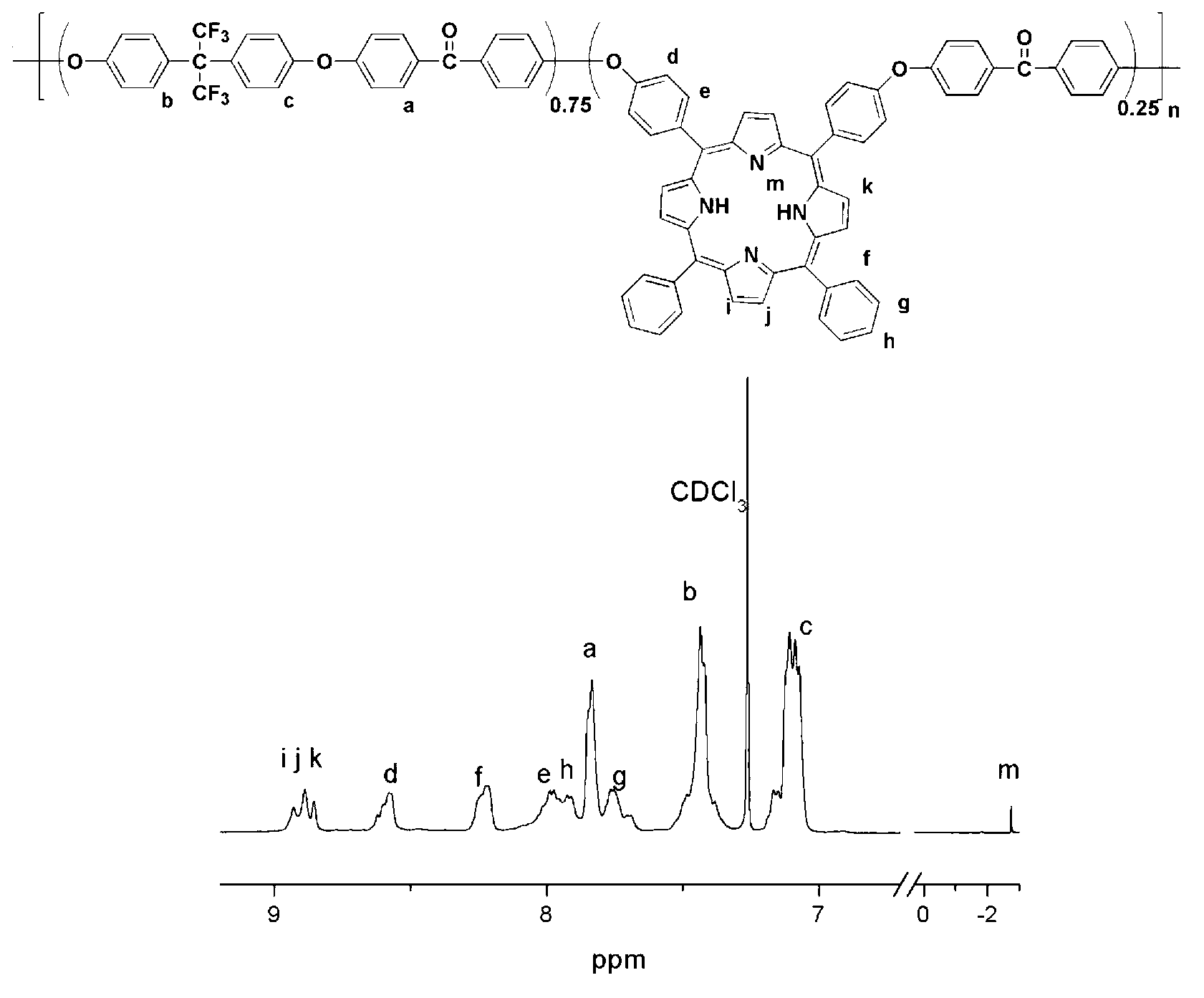

Polyaryletherketone copolymer containing porphyrin structure at main chain, and preparation method thereof

ActiveCN103319707AIncreased dispersionImprove thermal stabilityOrganic chemistryLuminescent compositionsPolymer scienceOrganic dye

The invention provides a polyaryletherketone copolymer containing a porphyrin structure at a main chain and a preparation method of the polyaryletherketone copolymer and belongs to the field of high polymer material preparation technology. Nucleophilic polycondensation is carried out on dyhydroxyl tetraphenyl porphyrin, aromatic organic bisphenol and 4,4'-difluoro diphenyl ketone to prepare the dissolvable polyaryletherketone copolymer. As the porphyrin has significant nonlinear optical effect, excellent thermal stability and chemical stability and is the representative of optical limiting organic dye molecules to be intensively researched by people, by introducing the porphyrin into the main chain structure of the polyaryletherketone, the three-stage nonlinear optical effect and the optical limiting property are provided to the polymer, and the heat resistance of the polymer is improved to a greater degree. A porphyrin-containing polyaryletherketone film prepared by the tape casting maintains better mechanical property and fluorescence characteristic. The polyaryletherketone copolymer containing the porphyrin structure at the main chain prepared by the invention possibly can be used for the fields of laser protection, nonlinear optics, fluorescence response detection and the like.

Owner:JILIN UNIV

Bisphenol A paraformaldehyde phenolic resin and preparation method thereof

InactiveCN112574371ASolve the pollution problemHigh molecular weightPolyoxymethyleneIndustrial waste water

The invention provides bisphenol A paraformaldehyde phenolic resin and a preparation method thereof, n-butyl alcohol is used as a solvent, p-toluenesulfonic acid is used as a catalyst, and bisphenol Aand paraformaldehyde are subjected to addition condensation reaction to obtain bisphenol A paraformaldehyde phenolic resin. The bisphenol A paraformaldehyde phenolic resin is produced by utilizing the characteristic that paraformaldehyde does not contain water, taking bisphenol A as a raw material, taking n-butyl alcohol as a solvent and taking p-toluenesulfonic acid as a catalyst and carrying out addition condensation reaction, the operation is simple, the environment is protected, the production cost is low, the synthetic route is easy to produce, the problem of environmental pollution caused by a large amount of industrial wastewater in the production process of phenolic resin is solved, and the synthesized product has high molecular weight.

Owner:SHAANXI UNIV OF SCI & TECH

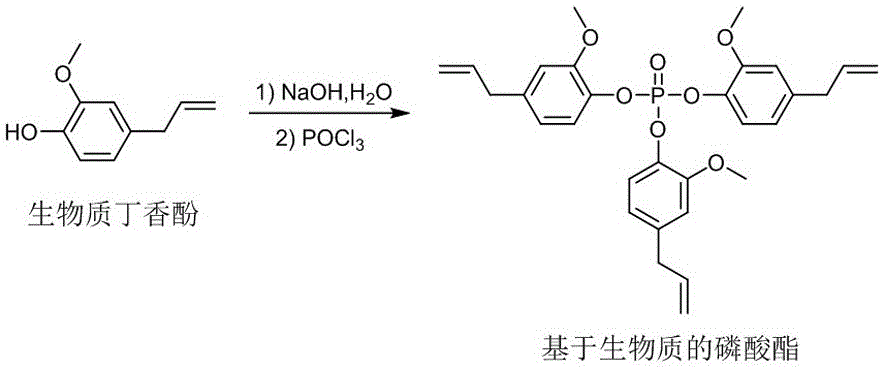

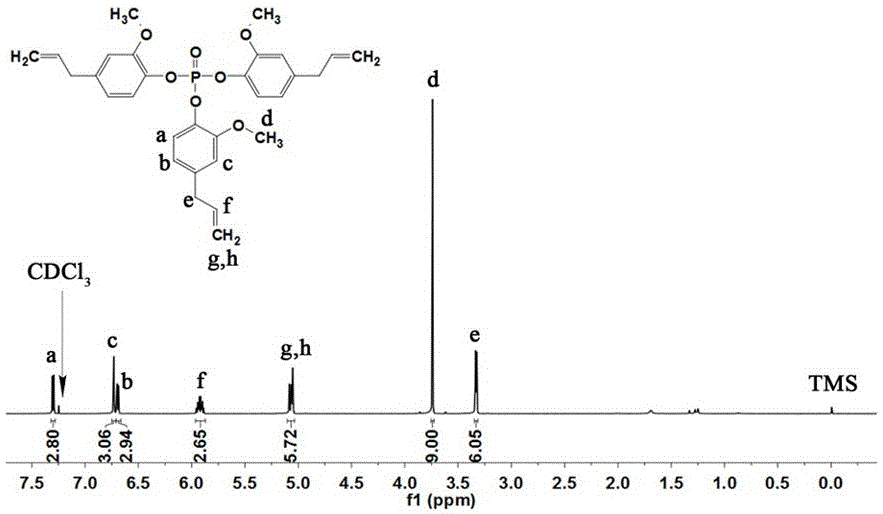

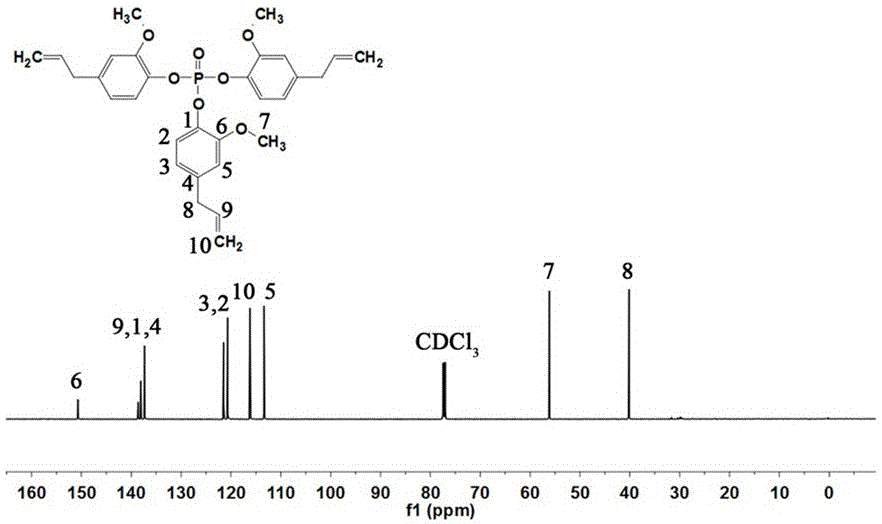

Flame-retardant bismaleimide resin and preparation method thereof

The invention discloses flame-retardant bismaleimide resin and a preparation method thereof. The preparation method is characterized in that full-biomass eugenol is processed into eugenol salt suspensoid under the effect of strong base of alkali metal; a chloromethane solution of phosphorus oxychloride is dropped to the eugenol salt suspensoid to react, so as to obtain a biomass-based phosphate ester flame retardant; bismaleimide and 2,2'-diallyl bisphenol A are mixed with the obtained phosphate ester; the mixture is subjected to solidifying and after-treatment, so as to obtain the flame-retardant bismaleimide resin. Compared with petroleum-based bismaleimide resin, the flame-retardant bismaleimide resin prepared by the method is prepared through a biomass-based raw material, namely, eugenol; the raw material is green and reproducible; the flame-retardant bismaleimide resin remains the mechanical property and processing property of the petroleum-based eugenol resin and is outstanding in flame retardant property. The preparation method has the characteristics of being low in cost, and simple in production process; the preparation method has a wide application prospect in the fields such as the aerospace field, the electronic information field and the electrical insulation field.

Owner:SUZHOU UNIV

Preparation method of bisphenol-A-bis(diphenyl phosphate) flame retardant

ActiveCN109912646AShort reaction timeHigh yieldGroup 5/15 element organic compoundsDiphenyl phosphateAcid washing

The invention discloses a preparation method of a bisphenol-A-bis(diphenyl phosphate) flame retardant. Firstly, bisphenol A reacts with excessive phosphoryl chloride, then, excessive phosphoryl chloride is removed, an obtained product reacts with phenol, and the bisphenol-A-bis(diphenyl phosphate) flame retardant is obtained. The bisphenol-A-bis(diphenyl phosphate) flame retardant is synthesized by a solid super acidic catalyst, so that the reaction time is greatly shortened, the reaction yield is increased, the product needs no acid washing and alkali washing processes, post-treatment steps are simplified, basically no wastewater is discharged, and compared with a Lewis acid catalyst, the solid super acidic catalyst reduces emission of 2.1 tons of wastewater for 1 ton of product.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

Preparation method of phosphorus-modified phenolic resin

The invention discloses a preparation method of a phosphorus-modified phenolic resin, which comprises the following steps: performing polycondensation on p-tert-octylphenol, nonylphenol, bisphenol A and formaldehyde under the action of a catalyst to obtain a phenolic condensation intermediate; and reacting the intermediate with monohydroxy alcohols and organic phosphorus heterocyclic compounds at a preset temperature for preset time under catalytic conditions to prepare the phosphorus-modified phenolic resin. The method solves the problem of complete dependency on the phosphorus-modified phenolic resin imported from abroad in the past, and enhances the heat resistance, binding strength, peel strength, favorable space size, excellent electric properties, mechanical strength and other physicochemical performance indexes of the original phosphorus-modified phenolic resin, so that the phosphorus-modified phenolic resin has relatively good application properties when being applied to the field of electronic chemicals.

Owner:梁劲捷

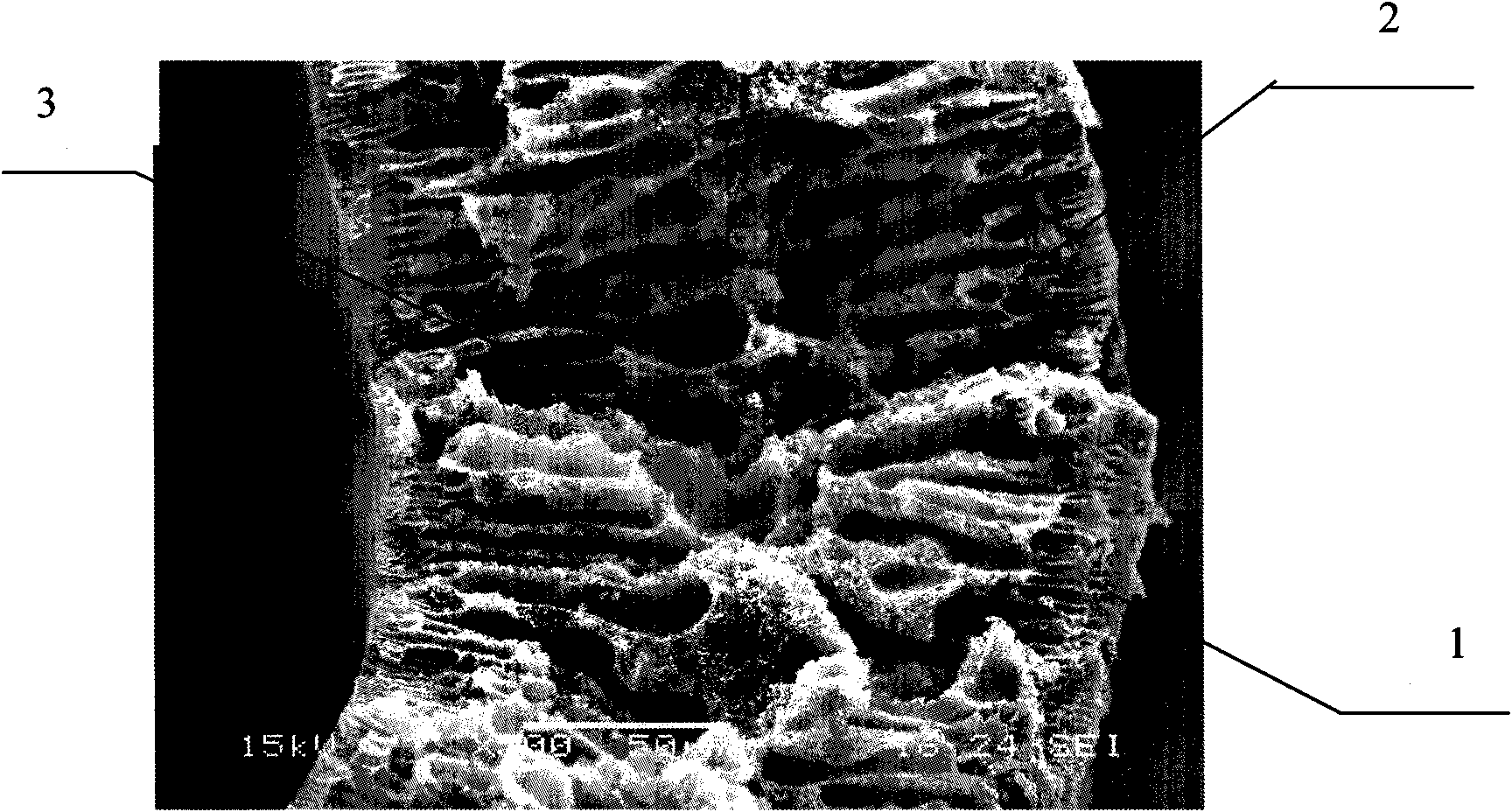

1,4 di[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof

InactiveCN101108807AEasy to manufactureMild reaction conditionsAmino preparation from aminesSolid-state devicesTriethylphosphitePolymer science

The invention discloses a 1, 4-2[4-(N, N-p-Methyl-phenyl-amino) styryl] naphthol and the preparation method and application, which belongs to the technology field of photoelectric materials. The structural formula of the component refers to the drawing and the preparation process of the component comprises that: 1-chloromethyl naphthalene reacts with paraformaldehyde and hydrochloric acid under the catalysis of the phosphoric acid to prepare 1, 4- dichloromethylnaphthalene and then reacts with triethyl phosphate to prepare the wittig reagent; the produced wittig reagent reacts with 4-(N, N-2 p-Methyl-phenyl-amino) aminotenzaldehyde under the action of alkali to gain the starting material. The component mixes with bisphenol A Pc resin or bisphenol Z Pc resin to prepare the hole-transporting layer thin film of the organic photoconductor of function separated type. The invention has moderate reaction conditions and has high photosensitivity of the organic photoconductor appliance as the hole-transporting material.

Owner:TIANJIN UNIV

Preparation of bisphenols salts

InactiveCN1583696AOrganic compound preparationCarbonyl compound preparationInorganic saltsOrganic solvent

Preparation of bisphenol double salts are prepared by reacting bisphenol with alkali in organic solvent inorganic aqueous salt solution, and filtering to directly obtain high purity products with yield>90%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

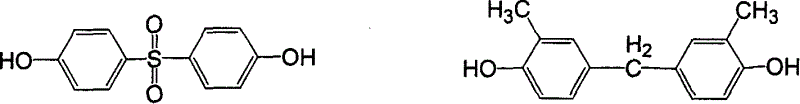

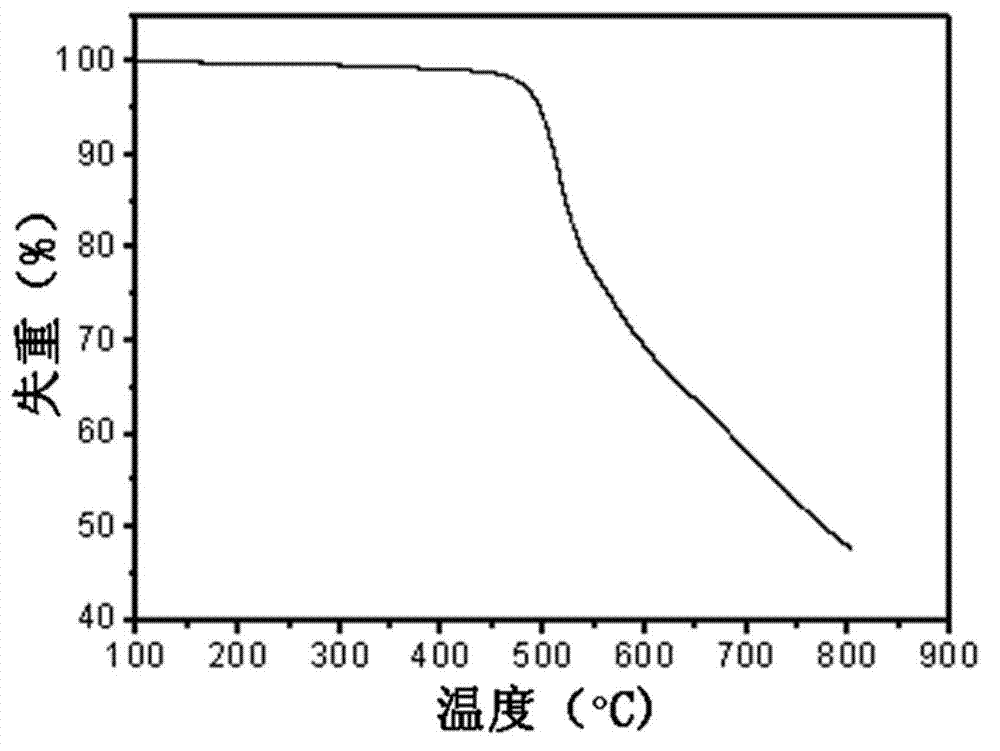

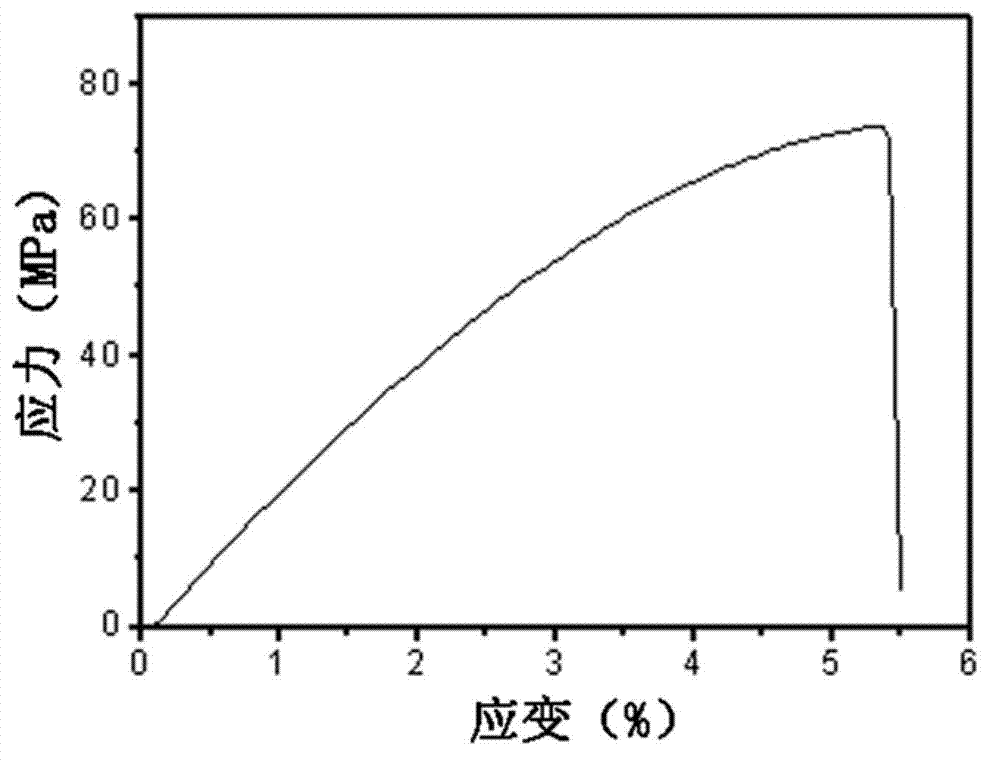

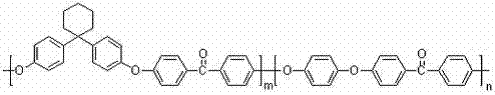

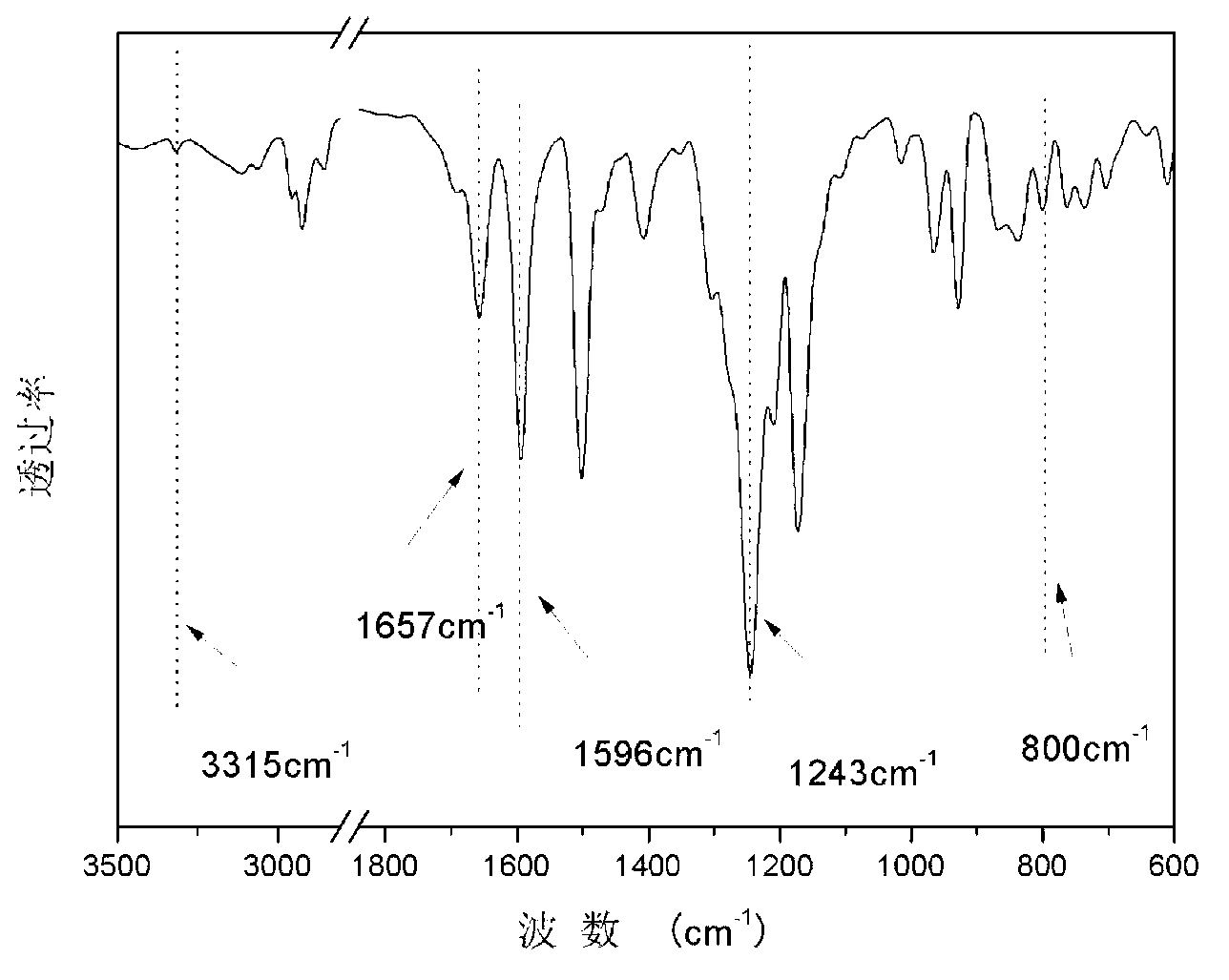

Bisphenol Z containing polyaryletherketone random segmented copolymer and preparation method thereof

The invention relates to a bisphenol Z containing polyaryletherketone random segmented copolymer and a preparation method thereof. The method comprises the following step of performing nucleophilic substitution polycondensation in a reaction medium to prepare the bisphenol Z containing polyaryletherketone random segmented copolymer based on bisphenol Z, hydroquinone and 4, 4-difluoro benzophenone as reaction monomers and an alkali metal salt as a salt-forming agent and catalyst. The bisphenol Z containing polyaryletherketone random segmented copolymer prepared by the invention is good in solubility, thermal stability and mechanical property, the raw materials are easy to obtain, and the preparation method is simple and suitable for industrialized production, so that the copolymer has good application prospect in the fields of functional structural materials, high-temperature-resisting coatings, high-temperature-resisting separation films, solvent coatings, micro-electronics and the like.

Owner:JILIN ZHONGYAN HIGH PERFORMANCE PLASTIC

Method for preparing bisphenol A rosin modified phenolic resin

ActiveCN102558476BRespond as soon as possibleEasy to control temperatureInksPolymer sciencePrinting ink

The invention discloses a method for preparing a bisphenol A rosin modified phenolic resin. The method includes reacting 4-tert-octylphenol, 4-nonyl phenol and bisphenol A with formaldehyde under the alkaline condition to obtain a bisphenol A modified solvent phenolic resin condensation compound, and subjecting the condensation compound to rosin modification, fumaric acid addition and esterification of mixed polyalcohol under the catalyst condition to obtain the bisphenol A rosin modified phenolic resin. The mixed polyalcohol comprises glycerol and pentaerythritol. According to the method for preparing the bisphenol A rosin modified phenolic resin, the prepared phenolic resin has the advantages that the softening point is high, adhesiveness is good, miscibility of the solvent is good, color and luster are light, molecular weight is uniformly distributed, and the phenolic resin is suitable for manufacturing of printing inks and applicable to being components of planographic or gravure printing inks.

Owner:桂林兴松林化有限责任公司

Hydrolysis-resistant and antistatic pc/asa alloy and preparation method thereof

The invention provides anti-hydrolysis anti-static PC / ASA alloy and a preparation method thereof. According to the method, condensation polymerization is conducted on PPR-MWCNT compounds and ASA-g-MAH grafted copolymer through bisphenol A and epoxy chloropropane, bisphenol A epoxy resin (EP-E51) and polycarbonate (PC) are obtained and are subjected to blending extrusion, and the anti-hydrolysis anti-static PC / ASA alloy is obtained. The prepared anti-hydrolysis anti-static PC / ASA alloy has excellent anti-static performance and excellent hydrolysis resistance, is suitable for the moist rainwater weather, has excellent impact toughness and lower processing viscosity, is easy to process and suitable for mass production and popularization, and can be oriented to automobile inside and outside ornaments such as an automobile rearview mirror shell body and an automobile door plank and outdoor sport equipment.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

Preparation method of bisphenol Z and bisphenol Z

PendingCN114436780ALow investment costReduce generationOrganic chemistryOrganic compound preparationCyclohexanonePtru catalyst

The invention discloses a preparation method of bisphenol Z and bisphenol Z. The preparation method comprises the following steps: by taking phenol and cyclohexanone as raw materials and solid acid as a catalyst, carrying out catalytic dehydration reaction, filtering, distilling and recrystallizing to obtain bisphenol Z; the solid acid is ion exchange resin or a molecular sieve. According to the method, a corrosive liquid acid catalyst is not used in the reaction process, and the operation process is simple, so that the requirement on production equipment is not too high. Most importantly, a large amount of water is not needed for cleaning after the reaction, so that the generation of wastewater is greatly reduced, alkali neutralization is not needed, the existence of salt is reduced, and the product quality is improved. In addition, compared with a liquid acid catalyst, the solid acid catalyst can be repeatedly used, so that the investment cost of the catalyst is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

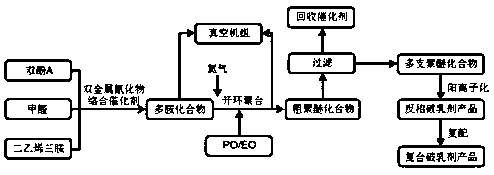

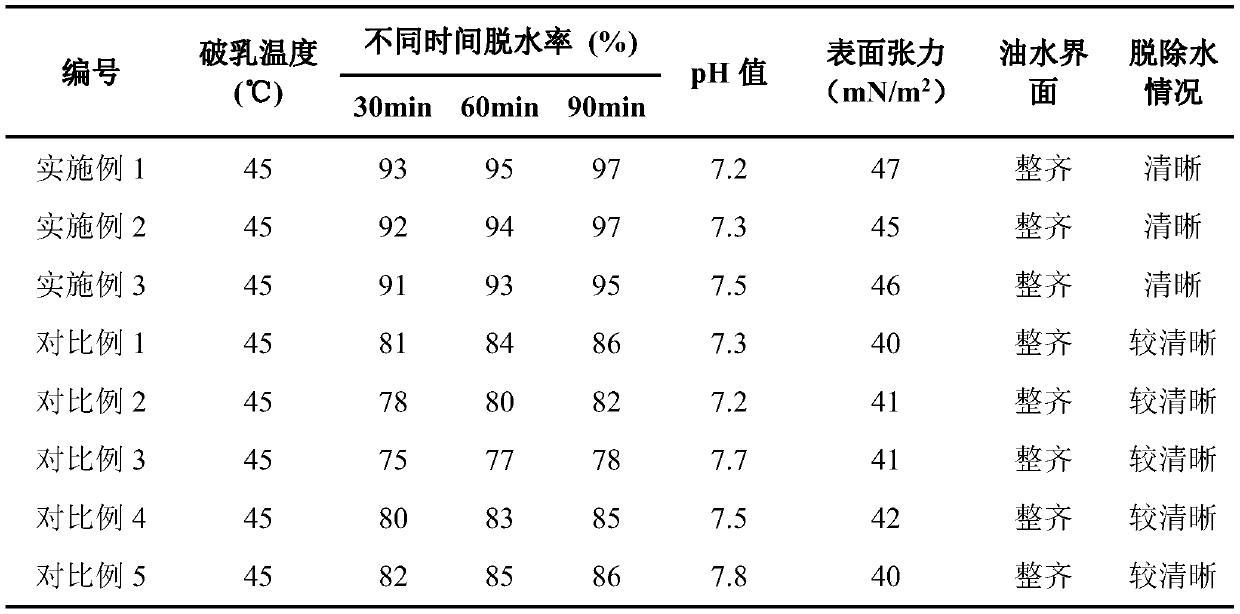

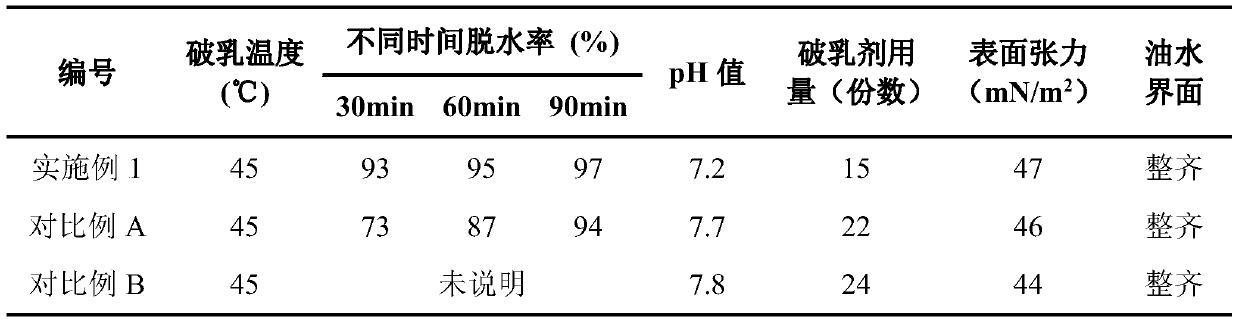

Preparation of demulsifier for rapidly dehydrating crude oil of offshore platform

InactiveCN111303936APromote demulsificationGood demulsification effectDewatering/demulsification with chemical meansHydrocarbon oils treatmentXylyleneDemulsifier

The invention discloses preparation of a demulsifier for rapidly dehydrating crude oil of an offshore platform. The synthesis and improvement process comprises the following step: (1) adding 2 parts of bisphenol A and 5 parts of triethylene tetramine into a four-neck flask, performing stirring and heating until complete dissolution, slowly adding 2.5 parts of a formaldehyde solution with the concentration of 40% in a dropwise manner when the temperature is 35-55 DEG C, conducting heat preservation for 35-45 min, adding 4.75 parts of xylene, increasing the temperature to 100-110 DEG C to removemoisture in the flask, continuing increasing the temperature to 185-195 DEG C to distill out xylene, and performing reaction on the remaining substances sufficiently for 1-2h to generate an initiator. The novel modified demulsifier has a good research prospect in the field of demulsification. The problems that after polymer flooding, produced liquid is high in emulsification degree, the demulsification difficulty is remarkably improved, due to the fact that the space of an offshore platform is limited, the emulsion treatment time of a land oil field can reach one day or even longer, but the treatment time on the sea is far shorter than the land treatment time, and the requirement for the demulsifier is stricter are solved.

Owner:BINZHOU UNIV

Compound polyether demulsifier and preparation method thereof

ActiveCN111592910AEasy to polluteReduce pollutionDewatering/demulsification with chemical meansHydrocarbon oils treatmentPolyamine CompoundBiochemical engineering

The invention discloses an efficient and environment-friendly compound polyether demulsifier and a preparation method thereof. The preparation method comprises the following steps: firstly, reacting bisphenol A with diethylenetriamine and formaldehyde to prepare a polyamine compound; polymerizing the branched cationic polyether with ethylene oxide and propylene oxide, and carrying out cationic modification to obtain a branched cationic polyether reverse demulsifier; and finally, compounding the prepared multi-branched cationic polyether reverse demulsifier with a biological demulsifier, a flocculating agent and a cross-linking agent according to a certain ratio, dissolving with a solvent, and uniformly mixing the components to obtain the compound polyether demulsifier. The efficient and environment-friendly compound polyether demulsifier prepared by the invention is high in demulsifying speed and good in demulsifying effect, the dosage of the demulsifier can be reduced, the damage to the environment is reduced, and the effects of environmental protection and energy conservation are achieved.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

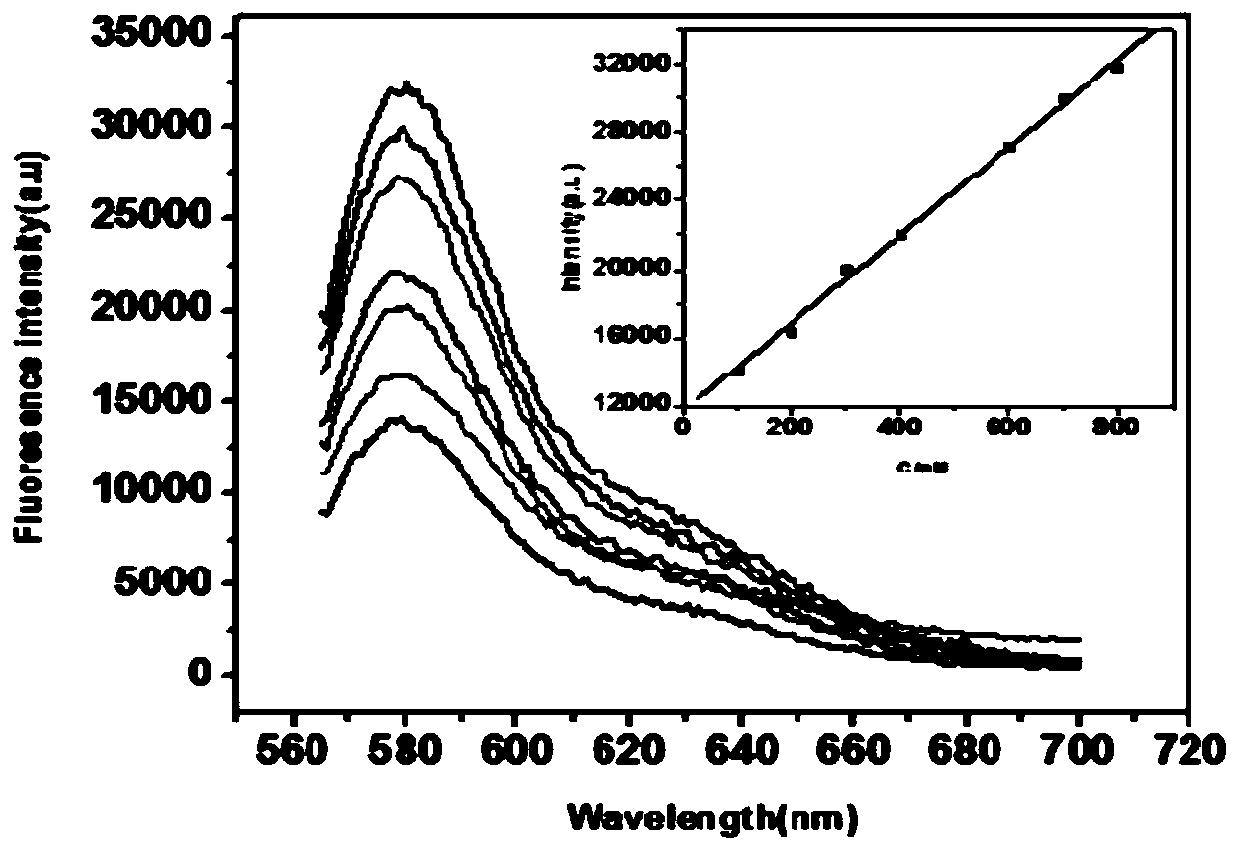

Method for quantitatively detecting bisphenol A

Owner:FUJIAN NORMAL UNIV

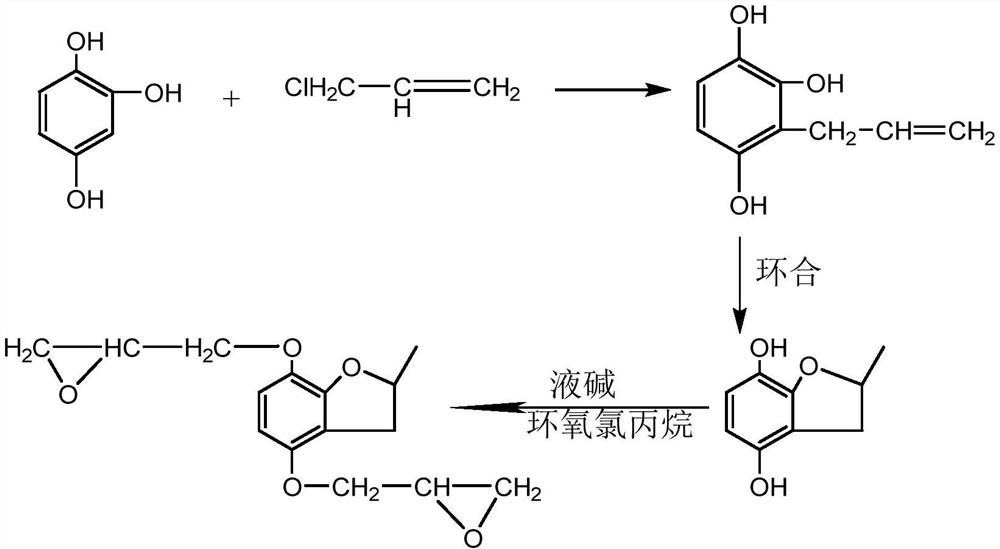

Preparation method of high-modulus heterocyclic epoxy resin

The invention discloses a preparation method of high-modulus heterocyclic epoxy resin. The preparation method comprises the following steps of: reacting benzenetriol with allyl chloride to generate 1-allyl benzenetriol, carrying out high-temperature transposition and cyclization to obtain heterocyclic bisphenol, reacting the heterocyclic bisphenol with epoxy chloropropane under the catalytic action of liquid caustic soda, and carrying out solvent refining to obtain the heterocyclic epoxy resin. After being cured, the heterocyclic epoxy resin has very high modulus, adhesion and weather resistance, has very good compatibility when being mixed with common epoxy resin, and can improve the overall performance of the epoxy resin.

Owner:山东天茂新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![1,4 di[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof 1,4 di[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof](https://images-eureka.patsnap.com/patent_img/3ba46d94-c2e6-4277-a954-1d1e3e55df67/A2007100580250002C1.PNG)

![1,4 di[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof 1,4 di[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof](https://images-eureka.patsnap.com/patent_img/3ba46d94-c2e6-4277-a954-1d1e3e55df67/A2007100580250002C2.PNG)

![1,4 di[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof 1,4 di[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof](https://images-eureka.patsnap.com/patent_img/3ba46d94-c2e6-4277-a954-1d1e3e55df67/A20071005802500041.PNG)