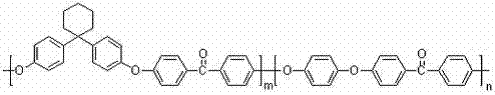

Bisphenol Z containing polyaryletherketone random segmented copolymer and preparation method thereof

A kind of random block, polyaryl ether ketone technology, applied in the field of polymer material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a three-necked flask reactor equipped with a stirring device and a reflux condensation water separation device, under nitrogen protection, add 44.31 g (0.2 mol) of 4,4'-difluorobenzophenone and 19.82 g (0.18 mol) of hydroquinone , bisphenol Z 5.367g (0.02 mol), 120 g diphenylsulfone and anhydrous potassium carbonate 26.40 g (0.197 mol), at 200-300 o Slowly raise the temperature between C and form salt for 2.5 hours, and then at 320 o C polymerized for 4 hours. The reaction product was poured into water for precipitation, crushed, washed with acetone backflush for 5 times, boiled with water for 5 times, filtered and dried (130 o C) Obtain ηi=0.80 dL / g (0.1% concentrated sulfuric acid solution, 25 o C) the polyaryletherketone block copolymer containing bisphenol Z, the productive rate is 95%.

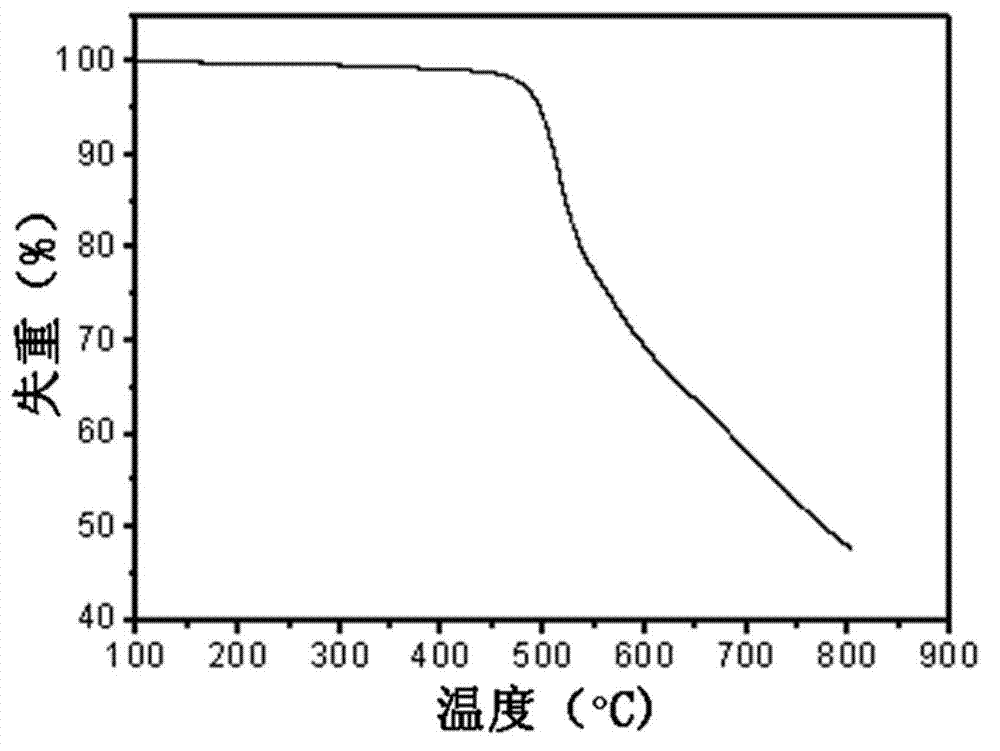

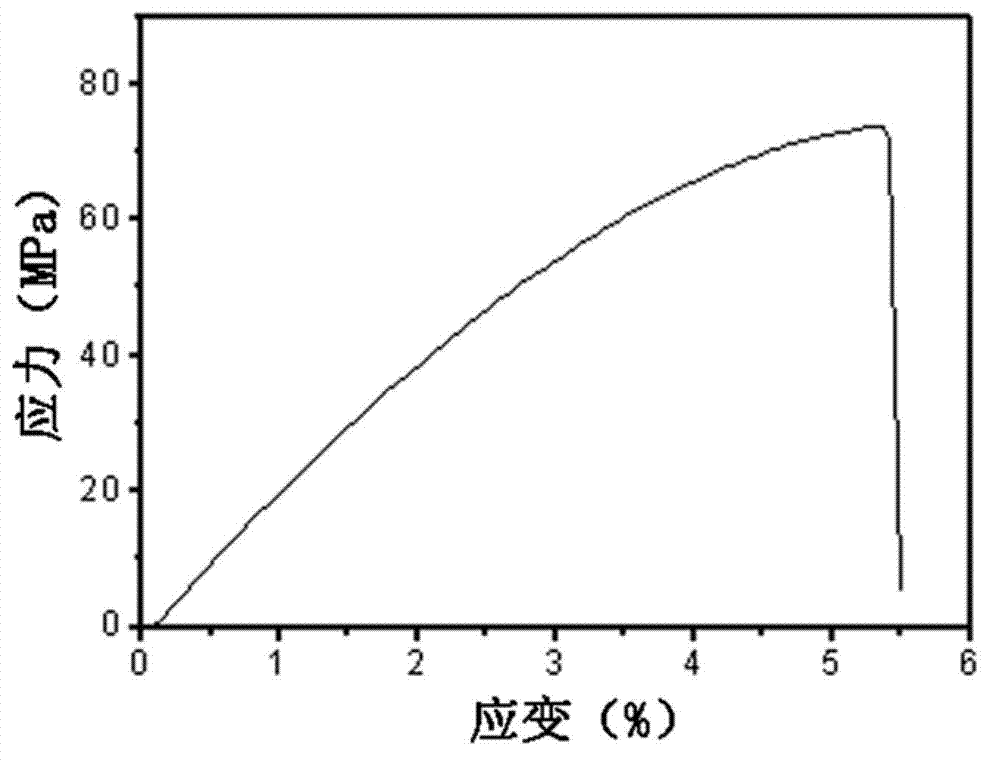

[0023] The thermogravimetric analysis curve and stress-strain curve of the obtained block copolymer are as figure 1 and figure 2 shown. From figure 1 It can be seen that...

Embodiment 2

[0025] In a three-necked flask reactor equipped with a stirring device and a reflux condensation water separation device, under nitrogen protection, add 44.31 g (0.2 mol) of 4,4'-difluorobenzophenone and 19.82 g (0.18 mol) of hydroquinone , bisphenol Z 5.367g (0.02 mol), 120 mL sulfolane and toluene 100mL, stir to dissolve, add anhydrous potassium carbonate 26.40 g (0.197 mol), stir and heat up to 120 o C salt-forming reaction for 2h, the water generated by the reaction is taken out, and then the temperature is raised to the next reaction temperature range, and toluene is released during the heating process, and the temperature is raised to 200 o After C reacted for 1h, continue to raise the temperature to 230 o C reacted for 4h. The reaction product was poured into water for precipitation, crushed, washed with acetone backflush for 5 times, boiled with water for 5 times, filtered and dried (130 o C) Obtain ηi=0.78 dL / g (0.1% concentrated sulfuric acid solution, 25 o C) the...

Embodiment 3

[0027] The method is the same as in Example 1, keeping the molar number of 4,4'-difluorobenzophenone unchanged (0.2 mol), changing the molar content of bisphenol Z to 0.06 mol, 0.08 mol, 0.10 mol, and 0.12 mol in sequence, while for The molar content of hydroquinone was changed to 0.14 mol, 0.12 mol, 0.10 mol, and 0.08 mol in turn. After the same steps as in Example 1, polyaryletherketone block copolymers with different bisphenol Z group contents were obtained, producing The rate is between 95% and 98%. The inherent viscosity ηi is between 0.60 dl / g and 0.92 dl / g. The obtained product has thermal properties and mechanical properties close to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Inherent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com