Epoxy resin nanometer montmorillonite composite material and preparation method thereof

A technology of nano-montmorillonite and epoxy resin, which is applied in the direction of epoxy resin coating, powder coating, coating, etc., can solve the problem of poor performance of epoxy resin nano-montmorillonite composite materials and the inability to provide epoxy resin nano-montmorillonite Soil composite materials and other issues, to achieve good performance and economic advantages, excellent impact strength and heat resistance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In order to overcome the defects in the prior art, the present invention proposes a preparation method of epoxy resin nano-montmorillonite composite material, which comprises the steps of montmorillonite acidification treatment, montmorillonite organic treatment and composite material synthesis. The purpose of acidification treatment is to make the K between montmorillonite layers + 、Na + , Ca 2+ , Mg 2+ The cations are transformed into soluble salts of acids and dissolved, thereby weakening the binding force between the original layers, cracking the interlayer lattice, expanding the interlayer distance, and significantly improving the surface area and adsorption capacity. The H in the acid + In addition to being able to replace the interlayer cations, it can also interact with the aluminum oxide octahedron, and some Al 3+ , Mg 2+ , Fe 2+ Plasma dissolution makes the montmorillonite negatively charged, and the particles become thinner due to the mutual repulsion of...

Embodiment 1

[0045] According to the process steps for preparing epoxy resin nano-montmorillonite composite materials proposed by the present invention, the montmorillonite is subjected to acidification treatment and octadecyltrimethylammonium chloride organic treatment, wherein the organic treatment process of montmorillonite The mass percent of octadecyltrimethylammonium chloride solution in the medium is 6%. According to the same components and component ratios, epoxy resin nano-montmorillonite composites were prepared by in-situ polymerization synthesis and blending synthesis.

[0046] Specifically, it is prepared according to the following composition and component distribution ratio. The molar ratio of bisphenol A: epichlorohydrin: sodium hydroxide is 1: 1.2407: 1.1987. The acidified and organically treated montmorillonite and bisphenol A The mass percentage is 5:95, and the epoxy resin nano-montmorillonite composite material is prepared in the reactor.

[0047] After testing, accor...

Embodiment 2

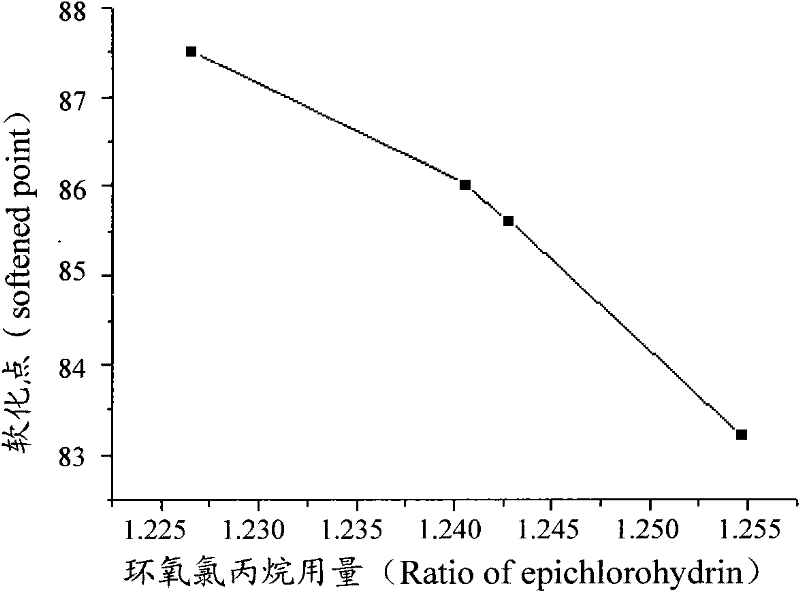

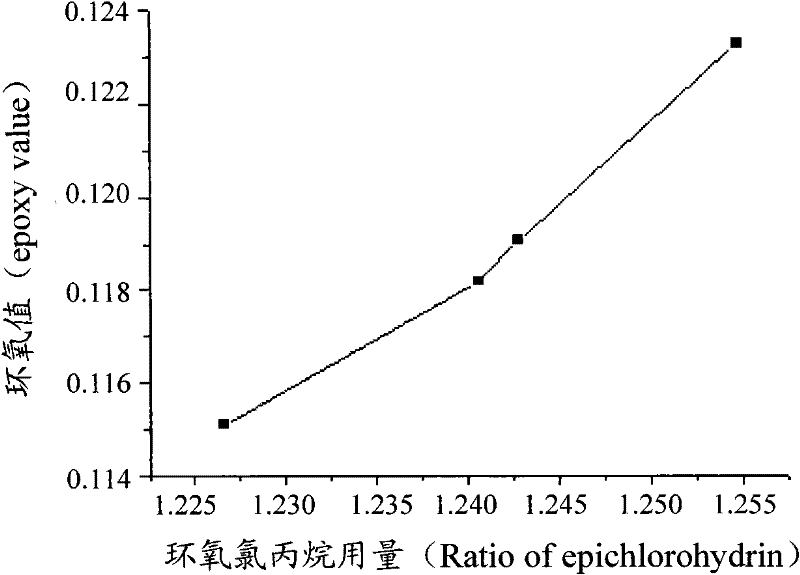

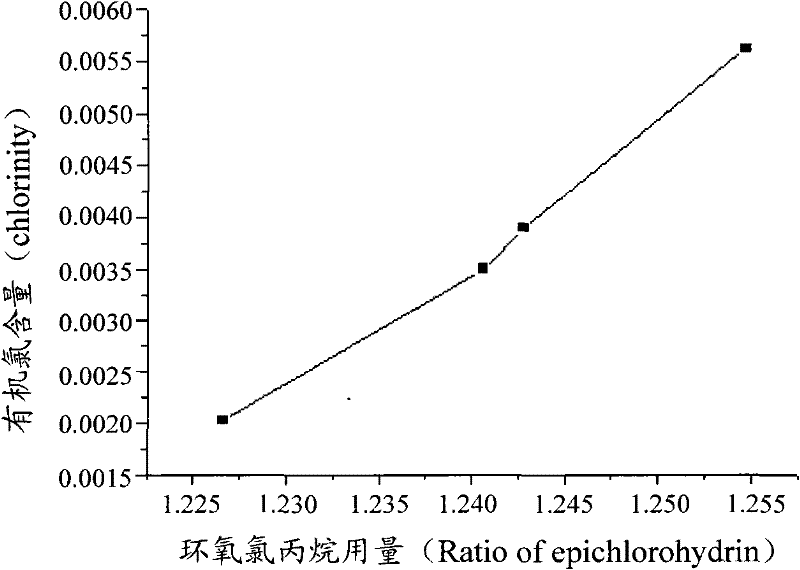

[0062] According to the processing step of preparing epoxy resin nano-montmorillonite composite material proposed by the present invention, when montmorillonite is carried out acidification treatment and octadecyltrimethylammonium chloride organic treatment, in the organic treatment of montmorillonite In the process, octadecyltrimethylammonium chloride solution with a mass percentage of 12% is used, and a co-mixing method is adopted, and epoxy resin nano-montmorillonite composite materials are prepared according to different component distribution ratios.

[0063] (1) Prepare according to the following composition and component distribution ratio: bisphenol A: epichlorohydrin: the mol ratio of sodium hydroxide is 1: 1.2267: 1.1889, the montmorillonite and bisphenol A through acidification and organic treatment The mass percentage is 3:97, and the epoxy resin nano-montmorillonite composite material is prepared in a reactor by blending. After testing, the softening point of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com