Preparation method of high-modulus heterocyclic epoxy resin

An epoxy resin, high modulus technology, applied in organic chemistry and other directions, can solve the problems of brittleness, peeling, inconvenient operation, etc., and achieve the effect of simple preparation method, good compatibility, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

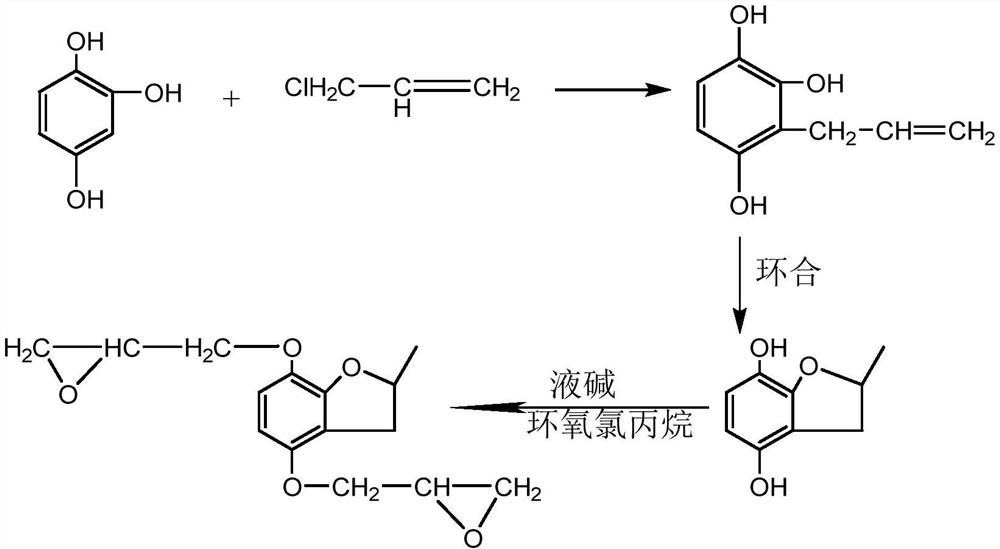

[0026] Embodiment 1: the preparation of high modulus heterocyclic epoxy resin

[0027] 1) Add 126g of 1,2,4-glucinol and 76.5g of allyl chloride into a 500ml four-neck flask equipped with a heating mantle, stirrer, and reflux condenser, and stir for 3 hours at a controlled temperature of 55-60°C;

[0028] 2) Then add 0.0665g of catalyst aluminum trichloride, heat up to 250°C, under negative pressure of 0.4MPa, transposition and cyclization occur for 80min, wash with water 3 times, and dry to obtain 152g of heterocyclic bisphenol;

[0029] 3) Weigh 100g of heterocyclic bisphenol and 100g of epichlorohydrin and heat to 30°C to fully dissolve, continue to heat up to 55°C, add 20g of 30% sodium hydroxide solution, keep warm for 2 hours, and continue to add 50% sodium hydroxide 46g of the solution was heated to 78°C, kept for 4 hours, washed 3 times with water, extracted 3 times with 200ml of acetone, combined the extracts, concentrated under reduced pressure to remove the solvent ...

Embodiment 2

[0035] Embodiment 2: Preparation of cured product of high modulus heterocyclic epoxy resin

[0036] 1) Add 126g of 1,2,3-glucinol and 77g of allyl chloride into a 500ml four-neck flask equipped with a heating mantle, stirrer, and reflux condenser, and stir for 2.5 hours at a controlled temperature of 55-60°C;

[0037] 2) Then add 0.08g of catalyst aluminum trichloride, raise the temperature to 260°C, and under the negative pressure of 0.4MPa, transposition and cyclization occur for 1.5h, wash with water 3 times, and dry to obtain 151g of heterocyclic bisphenol;

[0038] 3) Weigh 100g of heterocyclic bisphenol and 100g of epichlorohydrin and heat to 30°C to fully dissolve, continue to heat up to 58°C, add 22g of 30% sodium hydroxide solution, keep warm for 1.5h, continue to add 50% hydroxide 45g of sodium solution was heated up to 80°C, kept for 3.5h, washed 3 times with water, extracted 3 times with 200ml of toluene each time, combined the extracts, concentrated under reduced ...

Embodiment 3

[0039] Embodiment 3: Preparation of cured product of high modulus heterocyclic epoxy resin

[0040] 1) Add 126g of 1,3,5-glucinol and 77g of allyl chloride into a 500ml four-neck flask equipped with a heating mantle, stirrer, and reflux condenser, and stir for 2.5 hours at a controlled temperature of 55-60°C;

[0041] 2) Then add 0.07g of catalyst aluminum trichloride, raise the temperature to 260°C, and under negative pressure of 0.4MPa, transposition and cyclization occur for 1.5h, wash with water 3 times, and dry to obtain 151g of heterocyclic bisphenol;

[0042] 3) Weigh 100g of heterocyclic bisphenol and 100g of epichlorohydrin and heat to 30°C to fully dissolve, continue to heat up to 58°C, add 20g of 30% sodium hydroxide solution, keep warm for 1.5h, continue to add 50% hydroxide 45g of sodium solution was heated up to 80°C, kept for 3.5h, washed with water three times, added xylene for extraction three times, 200ml each time, the extracts were combined, concentrated un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com