Reduction-oxidation graphene-Fe3O4 nano composite, preparation method thereof, and application of reduction-oxidation graphene-Fe3O4 nano composite in absorbing bisphenol A

A nanocomposite material, -fe3o4 technology, applied in the field of nanotechnology and water treatment, to achieve the effect of simple preparation, less material consumption and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

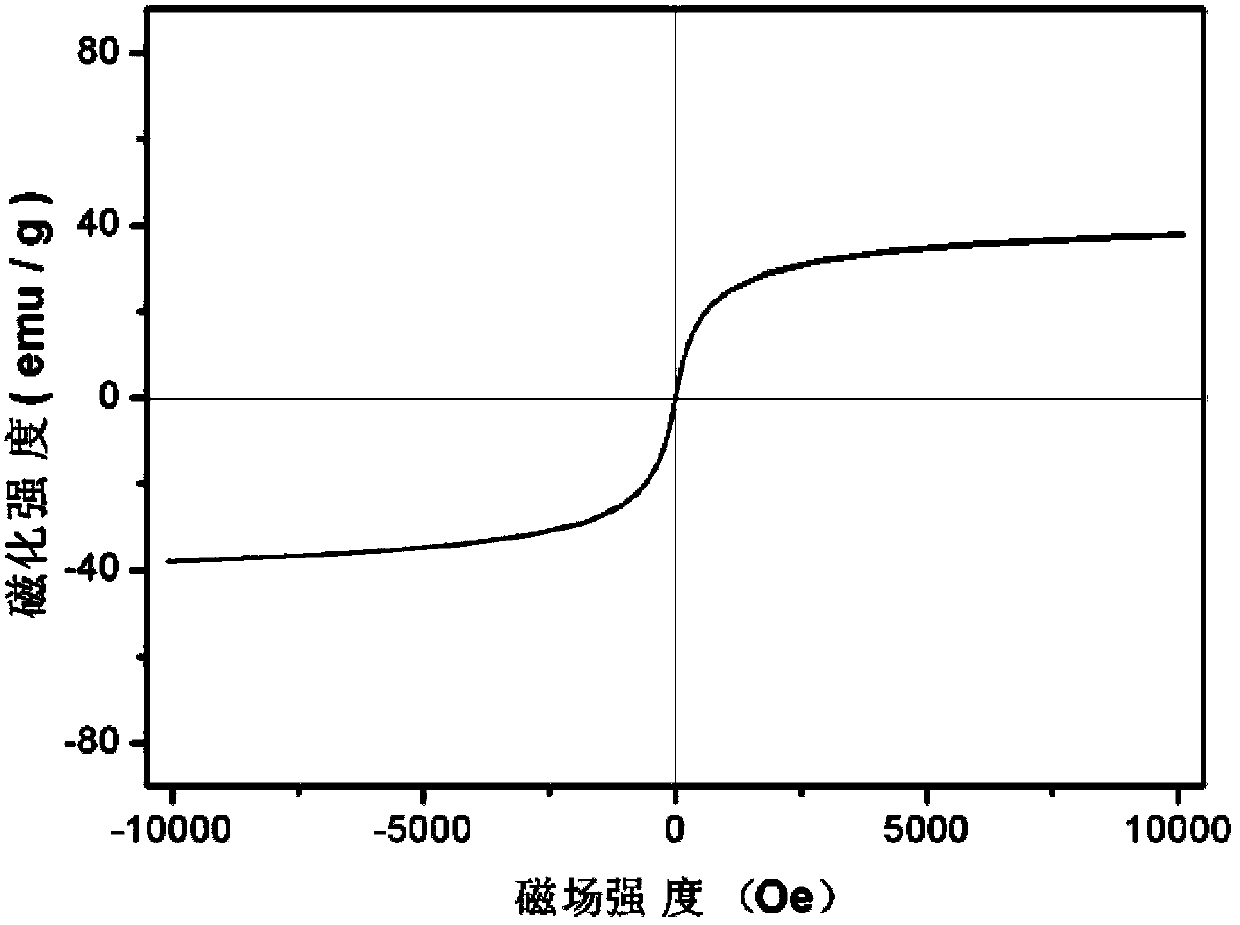

[0028] Reduced graphene oxide is ultrasonically dispersed in double distilled water, added with hydrazine hydrate and ammonia solution, stirred to obtain a uniformly dispersed solution, refluxed in an oil bath at 50-100°C, centrifuged and vacuum-dried to obtain reduced graphene oxide ; 200mg reduced graphene oxide, 172.2mg FeCl 2 4H 2 O and 280.95 mg FeCl 3 Dissolve in 200ml deionized water, then add 1.5mL NaOH (10molL -1 ), the final pH of the reaction system was controlled at 11-12, and then mechanically stirred at 80° C. for 1 hour to obtain a precipitate. The resulting precipitate was subjected to magnetic separation, washed with water and then vacuum-dried to obtain reduced graphene oxide-Fe 3 o 4 Nanocomposites with a saturation magnetization of 36 emu g -1 ,Such as figure 1 shown. Reduced graphene oxide structure into sheet shape, Fe 3 o 4 Nanoparticles are uniformly dispersed on the graphene surface, Fe 3 o 4 The average diameter of nanoparticles is about 10...

Embodiment 2

[0030] Take 50mL of wastewater solution containing 20mg / L BPA, pH=2-8, add 10mg of reduced graphene oxide-Fe to it 3 o 4 The nanocomposite material is stirred and adsorbed at room temperature for a certain period of time, such as 6 hours. The nanocomposite material was removed with a magnet, the content of bisphenol A in the solution after adsorption was detected, and the removal rate of bisphenol A in the solution was calculated. Bisphenol A removal rate and treatment time change curve such as Figure 4 As shown, with the increase of treatment time, the removal rate of bisphenol A in the solution gradually increased, and the adsorption reached equilibrium in about 2 hours, and the removal rate of bisphenol A reached about 96%.

Embodiment 3

[0032] The reduced graphene oxide-Fe adsorbed bisphenol A 3 o 4 After washing the nanocomposite with deionized water once, add 10mL of methanol, shake for 30min, and finally wash with deionized water for 2-3 times, dry it in an oven and put it into use again for the adsorption of bisphenol A. Refer to Example 2 application method. Reduced graphene oxide-Fe after regeneration 3 o 4 After the nanocomposite material is recycled 5 times, its adsorption capacity can still maintain 95% of its original value. Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com