Method for preparing bisphenol A rosin modified phenolic resin

A rosin-modified, phenolic resin technology, used in inks, household appliances, applications, etc., can solve the problems of difficult to control resin viscosity, increased operation difficulty, large water content, etc., and achieve uniform molecular weight distribution, good miscibility, and softening point. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

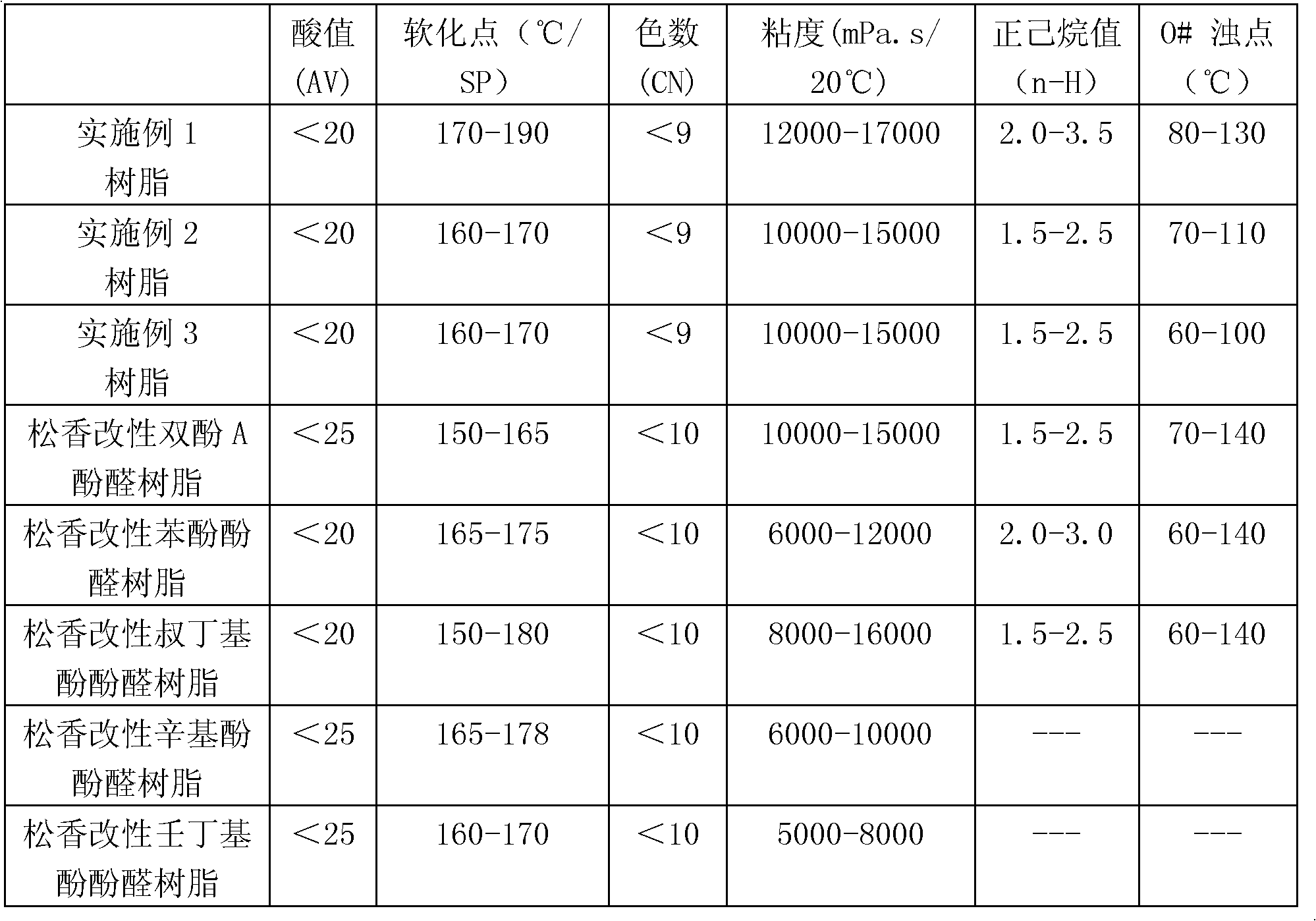

Examples

Embodiment 1

[0020] 1), the dimethylbenzene of 100 weight parts, the p-tert-octylphenol of 150 weight parts, the bisphenol A of 60 weight parts, the nonylphenol of 450 weight parts drop into reactor successively, be warming up to 65 ℃, be incubated 5 minutes, Then add 190 parts by weight of formaldehyde with a mass concentration of 92%, start stirring, then add 2 parts by weight of a 10% weight concentration of NaOH aqueous solution and 60 parts by weight of water in turn, heat up to 90 ° C, the heating rate is 1.0 ° C / min, and heat preservation is carried out. The reaction was carried out until the viscosity of the reactant in the reaction kettle was 10,000 mPa.s, cooled to 70°C, and taken out to obtain a condensation solution;

[0021] 2), drop the rosin of 1000 parts by weight into the reactor, be warming up to 180 ℃, add the fumaric acid of 40 parts by weight, be warming up to 200 ℃ and add the condensation solution that step 1) obtains, be incubated for 15 minutes;

[0022] 3), be war...

Embodiment 2

[0024] 1), the dimethylbenzene of 170 weight parts, the p-tert-octylphenol of 170 weight parts, the bisphenol A of 30 weight parts, the nonylphenol of 400 weight parts drop into reactor successively, be warming up to 50 ℃, be incubated 10 minutes, Then add 180 parts by weight of formaldehyde with a mass concentration of 94%, start stirring, then add 8 parts by weight of a 15% weight concentration of NaOH aqueous solution and 80 parts by weight of water in turn, heat up to 95 ° C, the heating rate is 1.0 ° C / min, and heat preservation is carried out. The reaction was carried out until the viscosity of the reactant in the reaction kettle was 19,000 mPa.s, cooled to 65°C, and taken out to obtain a condensation solution;

[0025] 2), drop the rosin of 2000 weight parts into the reactor, be warming up to 190 ℃, add the fumaric acid of 30 weight parts, be warming up to 195 ℃ and add the condensation solution that step 1) obtains, be incubated 30 minutes;

[0026] 3), be warming up t...

Embodiment 3

[0028] 1), the dimethylbenzene of 150 weight parts, the p-tert-octylphenol of 100 weight parts, the bisphenol A of 40 weight parts, the nonylphenol of 420 weight parts drop into reactor successively, be warming up to 75 ℃, be incubated 10 minutes, Then add 200 parts by weight of formaldehyde with a mass concentration of 96%, start stirring, then add 4 parts by weight of a 10% weight concentration of NaOH aqueous solution and 20 parts by weight of water in turn, heat up to 95 ° C, the heating rate is 1.0 ° C / min, and keep warm The reaction was carried out until the viscosity of the reactant in the reaction kettle was 15,000 mPa.s, cooled to 65°C, and taken out to obtain a condensation solution;

[0029] 2), drop the rosin of 1500 weight parts into the reactor, be warming up to 185 ℃, add the fumaric acid of 50 weight parts, be warming up to 205 ℃ and add the condensation solution that step 1) obtains, be incubated 20 minutes;

[0030] 3), be warming up to 225 ℃, add the glycero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com