Bisphenol A paraformaldehyde phenolic resin and preparation method thereof

A technology of paraformaldehyde and phenolic resin, which is applied in the field of phenolic resin, can solve the problems of difficult processing, harmful substances endangering the environment, etc., achieve the effect of high molecular weight and solve the problem of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

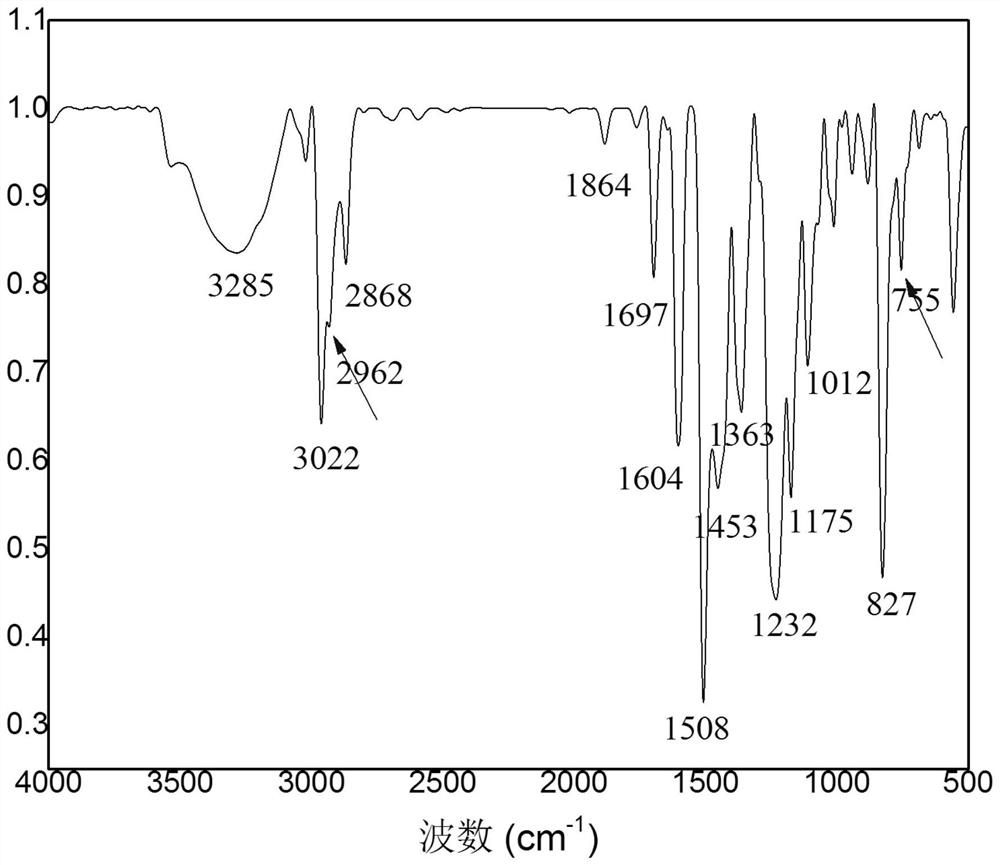

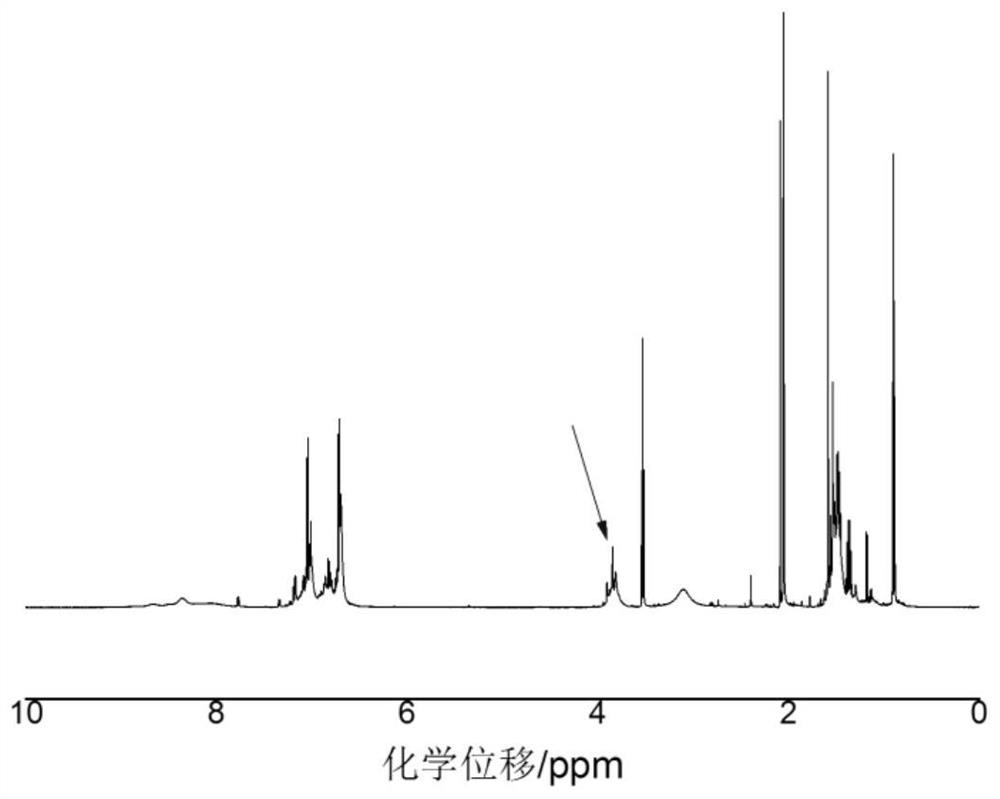

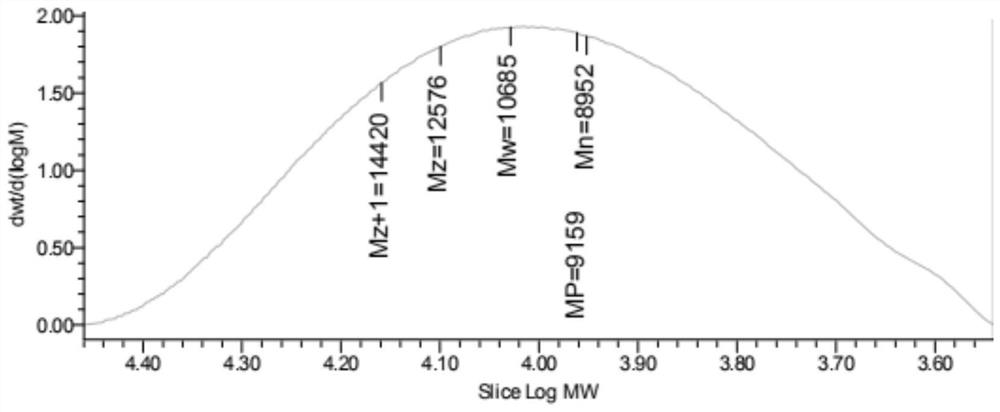

[0033] The preparation method of the bisphenol A paraformaldehyde phenolic resin is obtained through the addition and condensation reaction of bisphenol A and paraformaldehyde, wherein n-butanol is used as a solvent, p-toluenesulfonic acid is used as a catalyst, and the paraformaldehyde contains no water It can avoid the problem of environmental pollution caused by a large amount of industrial wastewater in the production process of phenolic resin, and can synthesize products with high molecular weight.

[0034] Wherein the polymerization process is as follows,

[0035]

[0036] Specifically include the following steps:

[0037] Step 1: Add 11.4g (ie 0.05mol) of BPA and 20-40mL of n-butanol to a 250mL four-neck round bottom flask equipped with a mechanical stirring and reflux device, stir and heat up to 50-70°C.

[0038] Step 2: When the BPA dissolved solution is clear, add 1-4g of paraformaldehyde, 0-3g of distilled water, 0.1-0.4g of p-toluenesulfonic acid in sequence, a...

Embodiment 1

[0043] The preparation method of bisphenol A paraformaldehyde novolac resin of the present invention specifically comprises the following steps,

[0044] Step 1: Add 11.4 g of BPA and 25 mL of n-butanol simultaneously to a 250 mL four-necked round bottom flask equipped with a mechanical stirring and reflux device, stir and raise the temperature to 65°C.

[0045] Step 2: When the BPA dissolved solution is clear, add 1.5 g of paraformaldehyde, 1.5 g of distilled water and 0.25 g of p-toluenesulfonic acid in sequence, and perform addition reaction for 10 minutes.

[0046] Step 3: Heating to 90° C., polycondensation reaction for 6 hours, and obtaining the crude product of bisphenol a paraformaldehyde novolac resin.

[0047] Step 4: Distill the reacted crude product under reduced pressure for 0.5 h (temperature 80° C., rotation speed 60 r / min) to remove n-butanol, water and unreacted paraformaldehyde.

[0048] Step 5: Use a dialysis bag with a molecular weight of 1000 to seal the ...

Embodiment 2

[0054] Step 1: Add 11.4 g of BPA and 20 mL of n-butanol simultaneously to a 250 mL four-necked round bottom flask equipped with a mechanical stirring and reflux device, stir and heat up to 50°C.

[0055] Step 2: When the BPA dissolved solution is clear, add 1 g of paraformaldehyde, 1 g of distilled water and 0.1 g of p-toluenesulfonic acid in sequence, and perform addition reaction for 10 minutes.

[0056] Step 3: Heating to 80° C., polycondensation reaction for 5 hours, to obtain the crude product of bisphenol a paraformaldehyde novolac resin.

[0057] Step 4: The reacted crude product was distilled under reduced pressure for 0.5h (temperature 60°C, rotation speed 60r / min) to remove n-butanol, water and unreacted paraformaldehyde.

[0058] Step 5: Use a dialysis bag with a molecular weight of 1000 to seal the obtained product, place it in 400ml of acetone, and use a magnetic stirrer for dialysis for 8 hours; Carry out drying in the case, obtain the bisphenol A paraformaldehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com