High temperature resistant pressure sensitive adhesive with excellent performance, pressure sensitive adhesive tape and preparation method thereof

A pressure-sensitive adhesive tape and high-temperature resistant technology, applied in the field of pressure-sensitive adhesives, can solve the problems of prone to residual adhesive or ghosting, difficult to achieve high temperature resistance, poor chemical structure uniformity, etc., to achieve excellent initial adhesion performance, excellent compatibility. Effects of Sex and Fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

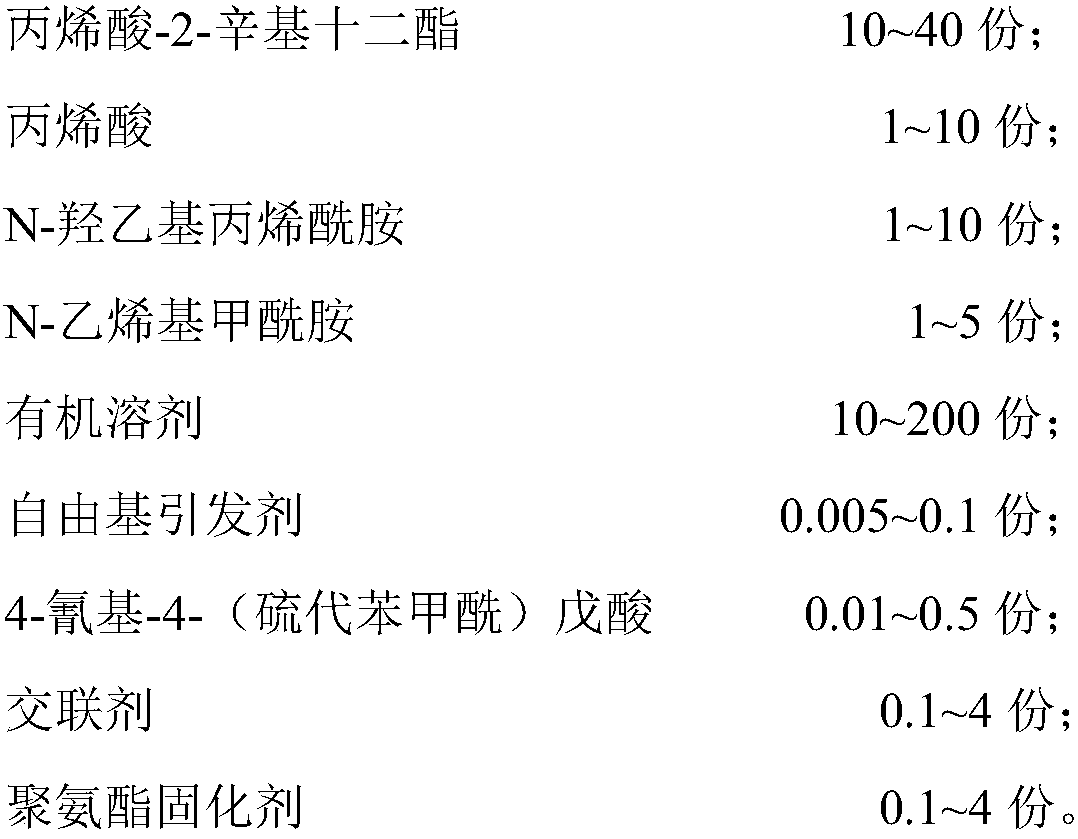

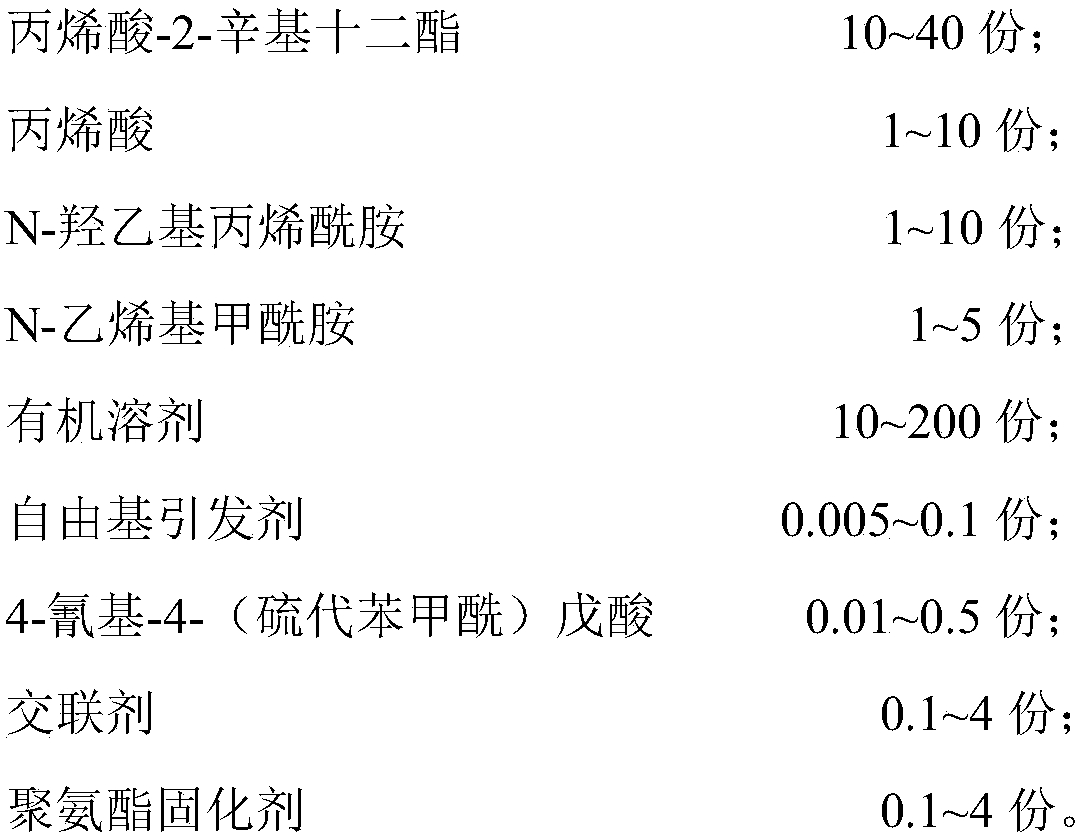

Method used

Image

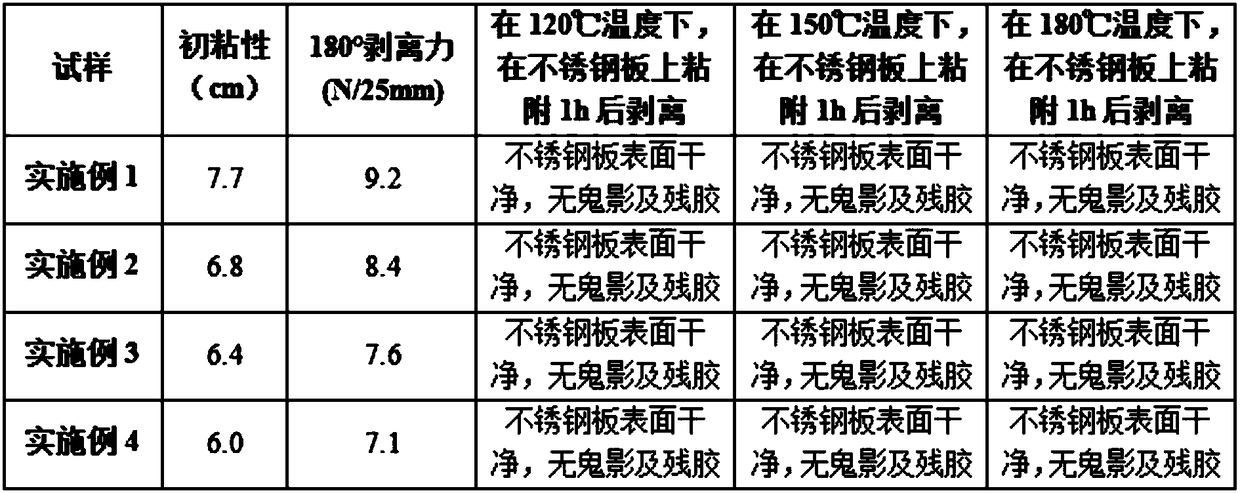

Examples

Embodiment 1

[0026] A high-temperature resistant pressure-sensitive adhesive with excellent performance and a pressure-sensitive adhesive tape applied with the pressure-sensitive adhesive, the preparation process is as follows:

[0027] 1) Synthesis of 2-octyl-1-dodecyl acrylate monomer

[0028] According to the mass parts of the raw materials, 80 parts of 2-octyldodecanol and 20 parts of acrylic acid were dissolved in 100 parts of dichloromethane, and 5 parts of 4-dimethylaminopyridine and 5 parts of 1-(3-bis (Methylaminopropyl)-3-ethylcarbodiimide hydrochloride, the temperature is controlled at 30°C, and the reaction is carried out for 50 hours to prepare 2-octyldodecanyl acrylate.

[0029] 2) Synthesis of high temperature resistant pressure sensitive adhesive

[0030] According to the mass parts of raw materials, 40 parts of 2-octyl lauryl acrylate, 5 parts of acrylic acid, 3 parts of N-hydroxyethyl acrylamide, 3 parts of N-vinyl formamide, 0.01 parts of peroxide Tert-Butyl-2-ethylhexanoate, 0...

Embodiment 2

[0034] A high-temperature resistant pressure-sensitive adhesive with excellent performance and a pressure-sensitive adhesive tape applied with the pressure-sensitive adhesive, the preparation process is as follows:

[0035] 1) Synthesis of 2-octyl-1-dodecyl acrylate monomer

[0036] According to the mass parts of raw materials, 60 parts of 2-ethyl-1-dodecanol and 15 parts of acrylic acid were dissolved in 80 parts of dichloromethane, and 3 parts of 4-dimethylaminopyridine and 3 parts of 1-( 3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, the temperature was controlled at 35° C., and the reaction was conducted for 60 hours to prepare the monomer of 2-ethyl-1-dodecyl acrylate in Example 2.

[0037] 2) Synthesis of high temperature resistant pressure sensitive adhesive

[0038] According to the mass parts of raw materials, 35 parts of 2-octyl lauryl acrylate, 7 parts of acrylic acid, 2 parts of N-hydroxyethyl acrylamide, 2 parts of N-vinyl formamide, 0.015 parts of peroxide Te...

Embodiment 3

[0042] A high-temperature resistant pressure-sensitive adhesive with excellent performance and a pressure-sensitive adhesive tape applied with the pressure-sensitive adhesive, the preparation process is as follows:

[0043] 1) Synthesis of 2-octyl-1-dodecyl acrylate monomer

[0044] According to the mass parts of raw materials, 40 parts of 2-ethyl-1-dodecanol and 10 parts of acrylic acid were dissolved in 70 parts of dichloromethane, and 2 parts of 4-dimethylaminopyridine and 2 parts of 1-( 3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, the temperature was controlled at 25°C, and the reaction was carried out for 70 hours to prepare the monomer of 2-ethyl-1-dodecyl acrylate in Example 3.

[0045] 2) Synthesis of high temperature resistant pressure sensitive adhesive

[0046] According to the mass parts of raw materials, 30 parts of 2-octyl lauryl acrylate, 8 parts of acrylic acid, 3 parts of N-hydroxyethyl acrylamide, 1 part of N-vinyl formamide, 0.03 parts of peroxide Tert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com