Pure adhesive film with core-shell structure and preparation method thereof

A technology of core-shell structure and pure rubber, which is applied in the field of pure rubber film with core-shell structure and its preparation, can solve the problems of poor heat resistance of pure rubber film, poor heat resistance of high viscosity, low peel strength of low viscosity, etc. Effects of marketing promotion, solder resistance, peel strength, and heat resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

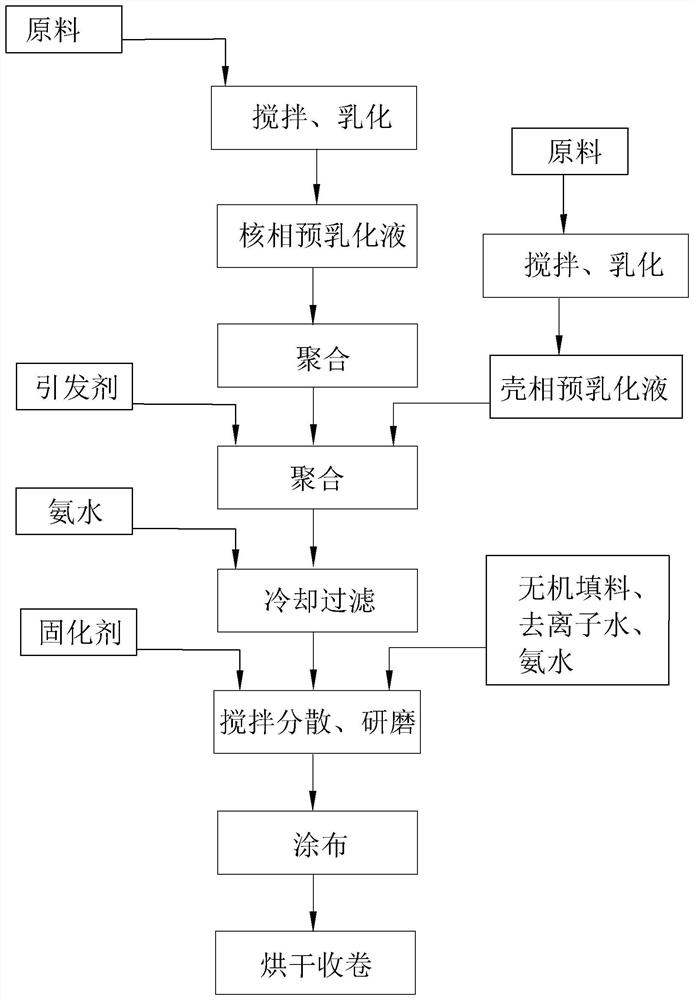

Method used

Image

Examples

preparation example 1

[0064] Preparation of curing agent: Take 9g of phenol, 20g of formaldehyde solution and 0.2g of triethylamine into the reaction tank, heat up to 50°C and stir at high speed for 60 minutes, then heat up to 70°C and continue to react for 90 minutes, after the reaction is completed, cool to room temperature and discharge to obtain solidified agent.

preparation example 2

[0066] The difference from Preparation Example 1 is that the amount of each raw material added is different, see Table 1 for details.

preparation example 3

[0068] The difference from Preparation Example 1 is that the amount of each raw material added is different, see Table 1 for details.

[0069] Each preparation example material addition of table 1

[0070]

[0071] It is worth noting that phenol is preferred in the preparation examples of this application. In other preparation examples, phenols can also be selected from one of resorcinol, m-cresol, dimethylphenol, p-tert-butylphenol, and p-phenylphenol. Aldehyde can also be selected a kind of in acetaldehyde, furfural, preferred formaldehyde in the application's preparation example; Catalyst preferred triethylamine, can also select a kind of in sodium hydroxide, potassium hydroxide, ammoniacal liquor in other preparation examples .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com