Double-component aqueous adhesive for automotive interior and preparation method of double-component aqueous adhesive

A water-based adhesive, two-component technology, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of high price and unstable bonding effect, and achieve good bonding strength and good application. Prospect, good initial tack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

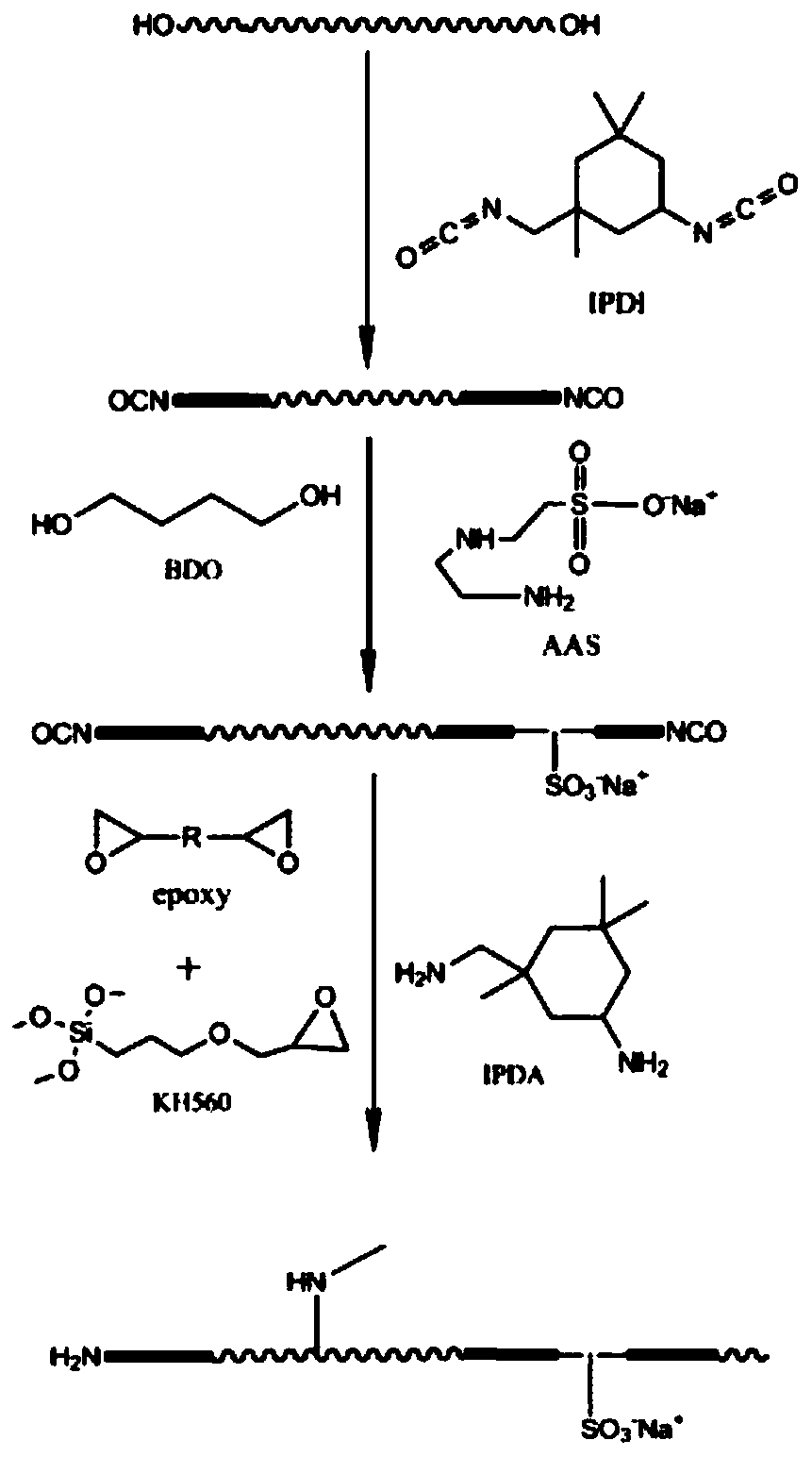

[0051] 1. Add 51g oligomer polyol (PEPA, molecular weight 2000, Huada Chemical Group Co., Ltd.), 24.3g IPDI, 0.19g bismuth laurate catalyst at 50°C, heat up to 85°C for 60min, cool to 60°C, add 12.8 g non-ionic hydrophilic monomer polyethylene glycol (PEG1000), 2.79g small molecule chain extender (1,4-butanediol, BDO), react for 30min, heat up to 80°C for 2h, cool down to 50°C and add 28.6 g acetone, add dropwise 2.08 g of sulfonic acid hydrophilic chain extender sodium ethylenediaminoethanesulfonate (AAS) for 30 min, cool down to room temperature, add 7.0 g of epoxy 828, and stir for 2 min to synthesize a polyurethane prepolymer.

[0052] II. Add 180g of deionized water to the polyurethane prepolymer for emulsification, stir at 1000r / min for 5min, then add 3.65gIPDA dropwise at 500r / min, finish adding dropwise in 20-40min, continue to react for 1h, remove the solvent in vacuum to obtain an emulsion.

[0053] III. Add 1% of polyurethane prepolymer quality non-ionic associative...

Embodiment 2

[0056] Add oligomer polyol under 1, 50 ℃, comprise: 35g polyester polyol (PEPA, molecular weight 2000), polypropylene glycol (molecular weight 2000) 10.5g, 27.5g dicyclohexylmethane diisocyanate, 0.18g bismuth laurate catalyst , heat up to 85°C for 60 minutes, cool down to 60°C, add 12.6g PEG1000, 2.5g 1,4-butanediol, react for 30min, heat up to 80°C for 2h, cool down to 50°C, add 27.5g of acetone, dropwise add 2.1g of ethyl alcohol Sodium diaminopropanesulfonate (A95, Beijing Baiyuan Chemical Co., Ltd.) was reacted for 30 minutes, cooled to room temperature and added with 7.0 g of epoxy E-44, 2.02 g of HDI trimer HT-100 (Wanhua Chemical Group Co., Ltd.), 0.87g KH560, stirred for 2min, to synthesize polyurethane prepolymer.

[0057] II. Add 78g of deionized water to the polyurethane prepolymer for emulsification, stir at 1500r / min for 5min, then add 3.72gIPDA dropwise at 300r / min, finish adding dropwise in 20-40min, continue to react for 1h, and remove the solvent in vacuum to...

Embodiment 3

[0061] 1. Add 28g polyester polyol (PEPA), 23.8gIPDI, 0.18g bismuth laurate catalyst at 50°C, heat up to 85°C for 60min, cool to 60°C, add 17.5g butanone, 12.6g PEG1000, 17.5g sulfonic acid Salt diol BY3305B (Beijing Baiyuan Chemical Co., Ltd.) 2.50g 1,4-butanediol, react for 30min, heat up to 80°C for 3h, cool down to 50°C, add 10.8g of acetone, dropwise add 1.75g of silane coupling agent KH550 for reaction After 30 minutes, cool down to room temperature and add 14.0g epoxy E-828, stir for 2 minutes to synthesize polyurethane prepolymer.

[0062] II. Add 174g of deionized water to the polyurethane prepolymer for emulsification, stir at 1500r / min for 5min, then add 6.6gIPDA dropwise at 500r / min, finish adding dropwise in 20-40min, continue to react for 1h, and remove the solvent in vacuum to obtain an emulsion.

[0063] III. Add 0.2% sodium carboxymethylcellulose thickener (Jinan Haoju Chemical Co., Ltd.) of polyurethane prepolymer and 0.1% preservative of polyurethane prepo...

PUM

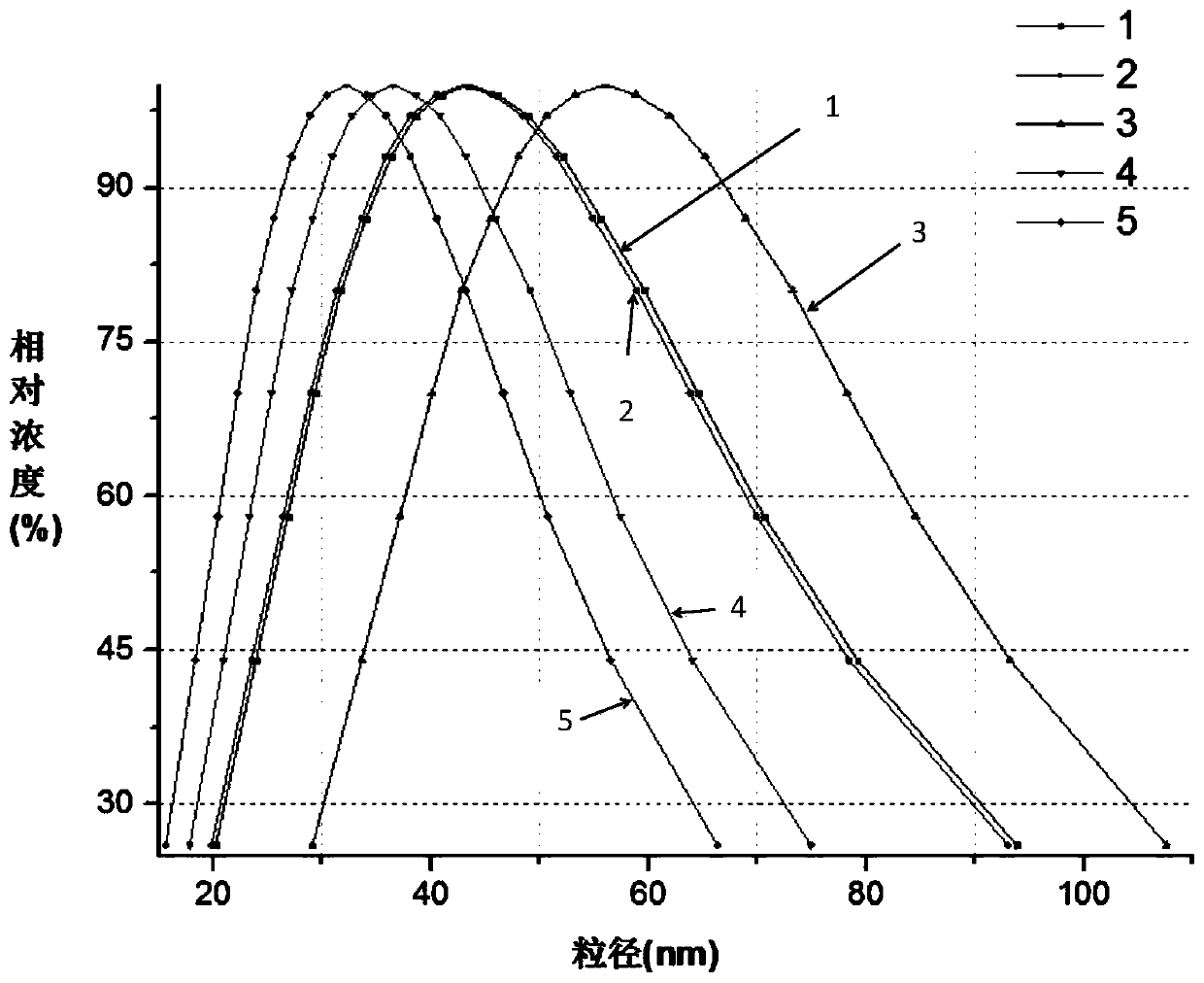

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com